Without juicy kebab, soaked in aromatic smoke, it is difficult to imagine a holiday in nature. Therefore, every self-respecting dacha owner tries to acquire a barbecue - a simple and convenient device for frying meat and fish.

At first glance, its design does not require any modifications. I made an iron box on legs, drilled holes in it, laid out the skewers and cook for your health. However, already at the first “baptism of fire” of the barbecue, several questions arise:

- I want to remove the smoke during kindling away from the resting place.

- An unexpected downpour can ruin the work of a home cook by flooding coals and meat.

Some are trying to solve these two problems “in one fell swoop” by installing a mobile barbecue in a summer gazebo. This eliminates the need to constantly run to it to check the readiness of the kebab, but fills the gazebo with smoke. The best way out of the situation is barbecues for a summer house with a roof. They protect the fireplace from rain, making the frying process comfortable and fast.

Features of metal structures

Metal barbecues can be either stationary for a summer residence, or mobile or folding. The first option is easier to assemble, as it only requires attaching legs concreted (or simply dug) into the ground. In this case, 2 supports submerged to a depth of 50-70 cm are sufficient.

Mobile structures are installed on more stable supports in the form of a sled or 4 legs. The wheels are attached to the bottom of the supports. Sometimes they install all 4, less often - 2 wheels so that the grill does not move when any pressure is applied to the side.

A folding metal barbecue is a box for coals, the legs of which are either completely detachable or mounted on fixed supports. This design option is convenient for those who like to go out into nature, have picnics, and hikes.

Brick

Construction always begins with a thoughtful layout of the territory.

As a rule, a brick structure is a spacious gazebo with a base. Instead of a conventional device, a unique device is being built with a barbecue, fireplace, grill and hob.

When drawing up a project, it is worth deciding on the dimensions of each element.

In any case, a foundation is required for the construction of a brick structure.

After drawing up the entire project and determining the dimensions of each of the elements, you can begin to work with the ground and prepare all the necessary materials.

You can build a barbecue with a roof by following these steps:

- First you need to dig a hole, which is intended for laying the future foundation . At the bottom of this depression it is necessary to pour a layer of sand no more than 70 mm high. Next, the mesh for reinforcement and prepared formwork are installed. Then the concrete solution is poured. It is important to remember that the height of the foundation must exceed the ground level by at least 100 mm. It is necessary to leave the base for some time so that it completely hardens. It should be noted that the foundation is built not only under the load-bearing walls of the gazebo, but also under the country barbecue with a roof.

- The formwork is removed, and a layer of roofing material is laid on the finished base, which is necessary to protect it from moisture. Next comes the construction of the barbecue itself . The first few rows are laid out with a layer of a continuous structure, and the subsequent ones - according to the drawn up project. The combustion chamber of a barbecue, barbecue or oven is made of bricks and mortar made from sand and clay. For all other elements, a composition based on cement and sand is used.

- After this you can start construction of a gazebo and roof. The pillars intended for support are made of brick. But you can also use metal pipes or wooden poles. The choice of roof shape depends on the design of the gazebo itself and the taste preferences of the owner. The chimney system of the device must end on the roof surface.

- Now you can decorate the built barbecue for the dacha and the provided recreation area. It is recommended to use ceramic tiles as a facing material. For the flooring, you can use tiles or make a concrete screed. Various roofing materials, such as metal tiles and metal profiles, are suitable for finishing the upper structure.

Dimensions and typical diagrams

When making a barbecue yourself, you can focus on the following parameters and features of their calculation.

Width

Determined by the size of the skewers. The length of typical products is 45-50 cm, of which the useful or working length is only 30-35 cm.

Consequently, the maximum permissible width of a typical barbecue is 40 cm. Then the meat will occupy maximum space above the coals, and the heat will not be wasted.

Length

It must be calculated based on the average number of kebabs. The recommended distance between two skewers is 5-10 cm. For 6 skewers, it is better to make a grill 60 cm long.

For a large company, when meat is fried on 10 skewers at the same time, a meter-long grill is suitable. And for barbecue grills, a 40 cm long roasting pan is optimal.

Dutch oven depth

The ideal value is from 15 to 20 cm. For frying meat, a layer of coals 5-10 cm high is enough, and the recommended distance between the skewers and the fuel is 8 cm.

For wood-burning grills, the depth is increased, but then more coals will be required for good roasting.

Grill height

This parameter is selected individually for the chef. It is believed that the brazier should be at the level of a person’s waist, then it will be convenient to work with the barbecue.

Depending on the height of the cook, the height of the grill can vary from 80 to 120 cm.

Frypan wall thickness

For stationary barbecues, the rule works: the thicker the walls of the firebox (broiler) of the barbecue, the better. It is advisable to use metal sheets with a thickness of 5-10 mm. Such a grill will retain heat better and last longer.

If you want to weld a portable structure, sheets 3-4 mm thick are suitable. Then the structure will weigh less.

Additional structural elements

- If you want to improve the design of the fryer, you can use a lid for this. This will significantly improve the fire and the degree of roasting of the meat in case of rain, hail or snow.

- Some people equip the grill with a special hood to ensure the outflow of excess smoke and combustion products. You will forever be able to forget that smoke completely fills the yard and all the free space under the canopy. This will make your holiday enjoyable regardless of the time of year.

- In order for the grill to be attractive and reflect some uniqueness, you can decorate it with a variety of decorative elements at your discretion. In this case, forged products come to the rescue. You can create them yourself if you have the necessary skills and equipment, or you can use the services of qualified craftsmen who offer to make them to order.

Advantages and disadvantages of a metal barbecue

Advantages:

- simplicity and a large number of design options;

- high assembly speed;

- possibility of self-production;

- relatively low cost when made by hand;

- high maintainability.

Flaws:

- The material is prone to corrosion, so it must be periodically tinted. At the same time, applying a protective coating to the outside of the coal box is useless; strong heat causes the protection to burn off;

- For manufacturing, you must have the appropriate skills and ability to work with tools.

Metal barbecues are popular and convenient; mobile models can be put away for the winter. However, the design itself is not very attractive; the box is covered with soot and does not decorate the area.

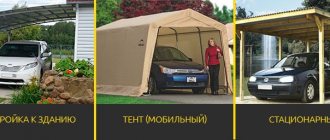

The main types of barbecue with a roof

The choice of a finished device with a canopy will not be limited to a simple design. There are many types of barbecue, among which you can choose exactly the one that will best suit your needs:

- requirements in terms of use and aesthetic appearance;

- financial capabilities of a person;

- taste preferences.

There are many models of grills with a canopy. The main types of devices are:

- barbecue grill;

- with a cauldron;

- barbecue gazebo;

- with stove;

- with an additional table.

Each type described has its own characteristics of use and performs special functions during cooking. Cooking food in this design becomes a real pleasure .

The roof can be created in such a way that all the smoke that rises up comes out through a kind of hood. Although in many cases the roof is created of a sloping type. This design helps precipitation not to stagnate, and additionally installed grooves and mesh create a complete drainage of excess water.

Instructions for self-production

Let's consider the process of assembling a barbecue made of metal. To make a simple model you need a minimum of materials and tools.

Tools and materials

Metal sheets 5 mm thick for the bottom and 3 mm for the walls

Steel pipes for making supports

Metal corner 20 mm for decorating the sides (you can also strengthen the connection between the bottom and the sides)

Grinder with cutting wheel

Welding inverter with a set of electrodes

Shovel or drill for making sockets for supports

Ruberoid, bitumen mastic for lining nests and applying a protective coating to supports

Protective paint for application on the grill

Expert opinion

Valery Garmash

Chef of the Grill House restaurant, griller

As a rule, heat-resistant black paint is used for painting so that the burnt edges do not stand out and create a contrast with the main coating.

Step-by-step instruction

We will show you how to assemble a simple grill yourself. Its design is so simple that any novice craftsman can make it.

For this purpose, a sheet of metal 2 mm thick was purchased from a metal warehouse. We recommend using metal with a thickness of at least 3 mm for the barbecue.

Since this grill (in our example) will not be used very often, 2 mm thick metal will be enough for us. Before starting work, for convenience, we made a small cutting diagram.

To obtain an even cut, you can use a regular iron strip as a guide bar.

When working, remember to use appropriate protective equipment.

Due to their design, homemade clamps are very helpful in work.

Once all the panels are cut, it's time to start drilling the holes. We decided to order a set of step drills for testing.

The optimal height of the grill sides is 150 mm. A row of holes is located at a height of 50 mm from the base. Hole pitch 60 mm. Diameter 12.4 mm.

The first impression of these drills is so far positive. The chips, as expected, come out of the hole in whole ribbons. I use a countersink to remove burrs.

We also place the recess for the skewers in increments of 60 mm.

It is best to process the sidewalls with a bag, pre-compressed with clamps.

When all the parts are ready, you can proceed to welding.

It is very convenient to use magnetic corners to secure parts.

We assemble the box using tacks.

Now you can scald.

It is not necessary to completely weld all the seams. We just wanted to practice welding one more time. We knock down the slag and clean the welds.

From 10 squares we make handles for easy carrying.

We will make the legs of the barbecue from 15 profile pipes, their length will be 80 cm. We trim the blanks using a cordless circular saw.

It will not be easy to get such an even cut with a regular grinder.

The legs will be attached using M6 bolts.

If necessary, this will allow you to store and transport the grill when folded.

To attach the legs, it is most convenient to use a wing nut.

When preparing barbecue, an additional work surface is never superfluous. A small shelf was quickly welded from 10 squares of reinforcement. It is installed in one movement in two sections of 15 professional pipes.

When all the work is completed, we clean all the parts and cover them with heat-resistant enamel. We wait for the paint to dry completely and you can assemble the grill.

The grill turned out to be very durable and quite stable. Its dimensions are as follows: height 80 cm, length 50 cm, width 30 cm, depth 15 cm.

When first ignited, the paint is fired within 15 minutes and it gains full mechanical strength.

The grill turned out to be very successful. Its design is so simple that even a novice welder can make such a grill.

Sometimes an awning or canopy is installed over the barbecue to protect the brazier from rain. The grill can also be painted with heat-resistant paint to protect against corrosion.

Usage: Tips

After each use, the collapsible grill must be cooled and thoroughly cleaned from soot and ash, which will certainly settle on its walls and bottom. It should be said that in no case should you put out the grill or cool it with water. The metal must cool exclusively naturally.

Another important tip is that after the end of the barbecue season, the grill must be disassembled and inspected for deformations. If defects are found, they must be eliminated, and chipped paint should be touched up. In addition, you need to lubricate various moving parts or awnings for the winter, if you used them.

As you can see, making a barbecue with your own hands is not so difficult. The main thing is to accurately calculate all the parameters, and also have minimal skills in working with metals. Thanks to this, you can easily and quickly make the grill of your dreams with your own hands and enjoy amazing kebabs at any time of the year.

The design of the barbecue for quick assembly (without welding or other fastenings) is clearly demonstrated in the video.