Pumps are used to supply water to a home or water a garden. They come in different types and designs, and each of them has its own area of application. If you need an inexpensive and reliable device for pumping water from a well, deck or some kind of container, pay attention to a self-priming pump. These are relatively inexpensive devices that are installed on the surface and can pump water from a fairly decent depth - 8-9 m. If necessary, the models are supplemented with ejectors, then the suction depth increases to 20-35 m.

General classification

Currently, there are more than three thousand types of pumps. They differ in structure and purpose, and are also suitable for different areas of use. All this variety can be divided into two large groups: dynamic and positive displacement pumps.

Volumetric pumps are devices in which a substance moves due to a constant change in the volume of the chamber, while it is alternately combined with the inlet and outlet. They, in turn, can be divided into:

- membrane;

- rotary;

- piston

Dynamic are models in which water moves along with the chamber due to hydrodynamic forces, while there is a constant connection with the inlet and outlet pipes of the pump. Dynamic pumps are either jet or vane pumps, the latter in turn being divided into centrifugal, axial and vortex.

Below, all these types of pumps, as well as their classification, will be discussed in more detail.

Impellers

The impeller is designed to convert the mechanical energy received by the pump from the drive into hydraulic energy and transfer it to the pumped liquid medium (water, wastewater, sludge, etc.). Radial impellers are made for centrifugal pumps. There are several designs of impellers. Let's look at the main ones.

The most common impeller is the one-way closed impeller, which consists of a front (outer) disk and a rear (inner) disk, which goes to the center of the impeller into a hub, which attaches the impeller to the pump shaft (Fig. 27, a). Between the disks there are blades that have either a cylindrical or spatial shape. Impellers of water pumps usually have 6–8 blades, while impellers of sewage pumps have 1–4 blades.

A double entry impeller (see Fig. 25) has a higher flow rate than a single entry impeller of the same diameter.

An open-type impeller is sometimes used in small pumps; it does not have a front disk and mates with the front cover of the pump with a small gap (Fig. 27, b). Pumps with such an impeller have reduced efficiency due to increased hydraulic pressure losses.

In most cases, impellers are made by casting, pouring metal into a mold, and only in special cases, for large pumps, are the impeller disks and blades made separately by casting or other means and then joined by welding.

For the manufacture of impellers, cast iron is mainly used, which provides sufficient strength, simplifies the production technology and reduces their cost. However, when rotating in the impellers of large pumps, high stresses arise from the action of centrifugal force, which can destroy the metal. Therefore, for such pumps, impellers are made of ordinary carbon steel, the strength of which is much higher than cast iron.

For special pumps pumping liquid media containing abrasive materials, impellers are made of manganese and other alloy steel with increased hardness. In some cases, for special pumps, the surface of the flow part of the impeller is lined, that is, lined with various materials (elastic, anti-corrosion, etc.). To supply a liquid medium with increased corrosive properties, pumps with bronze impellers are used. Acid pumps use impellers made of special alloys (iron-silicon, iron-chromium, titanium). In recent years, various plastics and polymer materials have been widely used for the manufacture of impellers.

Rotary devices

An overview of water pumps is opened by rotary devices. Their fundamental difference is the absence of a valve. In other words, a rotary water pump moves water by pushing it out. This process is carried out by a special working element - the rotor. This is implemented as follows: water enters the working chamber. The movement of the rotor along the inner walls of the working chamber forms a change in the volume of the enclosed space, and water is pushed out according to the laws of physics.

Advantages of rotary pumps:

- high efficiency;

- self-suction of water;

- Possibility of reverse water supply;

- pumping substances of any viscosity and temperature;

- low noise level;

- no vibration.

Of the minuses, it is worth noting that the purity of the pumped liquids must be ensured (without solid inclusions). In addition, the complex design requires expensive repairs.

Due to the ability to work with aggressive and viscous substances, rotary pumps are used in the chemical, oil, food, and marine industries. A subtype of rotary pumps - auger - is actively used in oil production. Another area of application is in public utilities, where they are used to maintain pressure in the heating system, while the pump does not require lubrication or cooling.

Characteristics of surface water pumps

A surface dimensional or mini pump is designed to draw liquid from a source that is located at some distance from the device. Such units can also be used for pumping water from pits and basements when performing construction or repair work. They are often used for watering a summer cottage, for an irrigation system, or for increasing pressure in a centralized water supply network.

The surface unit can be located in the basement, which should be dry and warm, in a separate extension or in a caisson near the well head. Its bottom should be located 0.5 m below the soil freezing level.

Related article:

Fountain pump: the heart of an artificial water source

Operating principle and purpose of the device. Types of units. Criterias of choice. Manufacturers. Installation. DIY pump.

Surface pumps are capable of lifting water to a height of 7-8 m, which depends on the design of the unit. They are characterized by high power and performance. Surface pumps are small in size, making them easy to operate. They are distinguished by their mobility and low cost. Surface equipment can pump water from a shallow source. It is more durable due to the fact that the metal structure does not come into contact with water.

A mini-pump for pumping 220 Volt water can be supplemented with automation, which will allow it to work in autonomous mode. In order for the unit to be able to lift water from a considerable depth, the pump is equipped with a remote ejector.

The surface pump for pumping water must be located at some distance from the source

Disadvantages include the formation of a high noise level during operation, a small immersion depth and high sensitivity to pumping contaminated liquid, which will lead to rapid wear of the internal mechanism of the unit.

Important! Some models of surface pumps require filling the line with water to start operating the unit.

Piston models

The piston pump design is based on mechanical displacement of water. This is one of the oldest types of water pumps, but in its modern form its design is much more complex than before. In particular, these pumps have an ergonomic and durable housing, a well-developed base of elements included in it, as well as flexible connection options to the water supply system. In this regard, they are widespread, both in industry and in everyday life.

The pump is a metal hollow cylinder, which, in fact, is a body - it moves liquid. The physical impact on it is carried out by a plunger-type piston, the operation of which can resemble a hydraulic press. The operation of this device is based on reciprocating movements. When moving upward (forward movement), a vacuum of air is created in the chamber, which ensures the suction of water. Water enters the chamber through an inlet with a valve, which at this moment opens the hole. During the return movement, this valve returns to its place and the outlet valve opens. At the same time, the piston squeezes out the water. The most common syringe works on almost the same principle.

There is one drawback to such work - the liquid flows unevenly. To eliminate this phenomenon, several pistons are used at once, which move at a certain frequency, which ensures an even flow.

There are double acting piston pumps. Here the valves are located on both sides, and water passes several times throughout the entire cylinder, that is, the piston, when moving, distils water inside the working space and pushes some of it out of the pump. Due to this, it was possible to reduce pulsation in the pipeline. The double-type design has a disadvantage - it is a more complex system, which makes it less reliable.

The main advantage of piston pumps is simplicity and durability, the main disadvantage is low productivity . In general, this type of pump can be made more efficient, but this does not make sense, since other types of pumps for pumping water can provide greater power at lower cost.

The scope of application of such pumping equipment is quite wide. They allow you to work not only with water, but also with aggressive chemical environments, as well as explosive mixtures. Due to the fact that such devices cannot pump large volumes of liquid, they are not used for large tasks. However, similar pumps are often found in the chemical industry. They can also be used to provide an autonomous water supply system for the home or for irrigation. Another place where such devices have proven themselves successfully is the food industry. This is explained by the fact that piston models are sensitive to the substances passed through them.

Popular water pump manufacturers

One of the popular manufacturers of water pumps is the Italian company Calpeda. It is considered a recognized leader in the global pumping equipment market. The pumps produced by this company are considered the most reliable in the world. They are manufactured using high-precision equipment, highly qualified personnel work in production and, moreover, the company is famous for its good technical traditions. Absolutely all materials and spare parts for Calpeda pumps are made in Italy.

In addition to this recognizable brand, there are also Gardena or Makita, which are also quite recognizable brands. They are stable and reliable companies that today are only increasing their potential.

Membrane devices

A diaphragm pump is a relatively new type of equipment for pumping liquids and other substances. This type of equipment is capable of working with a gaseous medium and does this through a special membrane or diaphragm. It performs reciprocating movements and changes the volume of the working chamber with a given cyclicity.

The device design includes:

- membrane;

- working chamber;

- rod for connecting the diaphragm to the drive shaft;

- crank mechanism;

- valves to protect against backflow of substances;

- inlet and outlet pipe.

Such pumps may have one or two working chambers. Devices with one camera are more common, while devices with two are used in places where higher performance is required.

The work is carried out as follows: when starting, the rod bends the membrane, which increases the volume of the chamber and creates a vacuum effect in it. This phenomenon ensures the suction of the pumped medium. After filling the chamber, the rod returns the membrane to its place, the volume decreases sharply, and the substance is pushed out through the outlet pipe. At the same time, in order to prevent liquid or gas from getting back during the return movement, the inlet is automatically closed with a special valve.

There are models with two valves located parallel to each other. Here the process is carried out in a similar way, only there are two working chambers, and with each movement, water leaves one and enters the other. Such devices are considered more efficient.

Advantages of diaphragm pumps:

- can work with any environment;

- small size;

- quiet operation;

- no vibration;

- simplicity and reliability of design;

- energy efficiency;

- maintaining high purity of the pumped substance;

- low price;

- long service life;

- do not require special or frequent care, they do not need lubrication;

- a person without special education can replace damaged parts;

- have high versatility.

With such an abundance of advantages, no significant disadvantages were identified.

The diaphragm pump is widely used in medicine and pharmaceuticals, on farms (in milking machines). They are used for food production and in the nuclear sector. With their help, dosing pumps are made for use in the production of varnishes and paints; they are used in printing and in various places where there is a need to work with toxic and dangerous substances. It is safe to work with the latter, since diaphragm pumps have high tightness.

Characteristic features of aquarium pumps

An aquarium pump, also known as a compressor, aerator or pump, is designed to circulate water in a tank in order to saturate it with oxygen for the normal functioning of its inhabitants. Aeration is performed around the clock, ensuring a stable air exchange regime. Such pumps are used to mix the upper and lower layers of water in order to equalize the temperature of the liquid, thereby preventing its changes. The operation of the device helps to destroy the oily, unpleasant film that interferes with normal gas exchange.

The operation of an aquarium pump for pumping water is as follows. There is a motor inside the compressor. It takes oxygen from the room and forces it into a tube, pumping it to the sprayer, which is located in the aquarium.

The pump can operate on mains power or independently on batteries. There are one- and two-channel models. The latter option is characterized by durability, small size, low noise and high performance.

Based on their design components, aquarium pump pumps come in vibration and diaphragm types. The first type is characterized by high power and durability. The equipment operates quite noisily, creating vibrations. It is recommended to install a piston unit for aquariums with a capacity of more than 200 liters.

An aquarium pump is used to circulate water in a tank to saturate it with oxygen.

The diaphragm pump makes virtually no noise and has low power consumption. However, such a unit is characterized by poor performance, so it is advisable to use it for aquariums with a capacity of up to 150 liters.

Depending on the installation option, there are surface and submersible 12 Volt water pumps for an aquarium. The first type is attached using special suction cups or clamps under water to the bottom of the aquarium. The surface version is installed outside the fish tank. Only air tubes are supplied to it.

Important! A surface aquarium pump is used for small tanks when keeping particularly demanding fish.

Jet pumps

Inkjet models are the simplest of all possible devices. They were created back in the 19th century, then they were used to pump water or air from medical test tubes, and later they began to be used in mines. Currently, the scope of application is even wider.

The design of the jet pump is very simple, thanks to which they practically do not require any maintenance . It consists of four parts: suction chamber, nozzle, diffuser and mixing tank. The entire operation of the device is based on the transfer of kinetic energy, and no mechanical force is used here. The jet pump has a vacuum chamber into which water is sucked. Then it moves through a special pipe, at the end of which there is a nozzle. By reducing the diameter, the flow speed increases; it enters the diffuser, and from it into the mixing chamber. Here water is mixed with the functional fluid, due to which the speed is reduced, but the pressure is maintained.

Jet pumps come in several types: ejector, injector, elevator.

- The ejector only pumps the substance. Works with water.

- The principle of operation of an injection pump is the injection of a substance. Used to pump out steam.

- Elevator is used to lower the temperature of the carrier, which is achieved by mixing with a functional liquid.

Thus, jet pumps are used to handle water, steam or gas. They can also act for mixing different substances or for lifting liquids (aerolift function).

This type of pump is common in various industries. They can be used separately or in combination with others. The simplicity of the design allows them to be used in emergency situations with water outages, as well as for fire extinguishing. They are also popular in air conditioning and sewage systems. Many jet-type models are sold with a variety of nozzles.

Pros:

- reliability;

- no need for constant maintenance;

- simple design;

- wide scope of application.

Minus - low efficiency (no more than 30%).

What is a 12 Volt water pump?

A special category of pumping equipment includes small 12 volt water pumps. They can be used for watering a vegetable garden, garden, pumping liquid from sources into reservoirs, for draining and flushing a well or well, washing a car, filling and draining artificial reservoirs, aquariums of various sizes.

The 12 volt water pump is no different from its large-sized counterpart. It consists of a housing, impeller and shaft made of stainless steel, a wet-type rotor, bronze elements of the hydraulic system, connecting fittings, and a mechanical cleaning filter, which protects the device from the ingress of large solid particles of debris larger than 0.5 mm.

The 12 volt pump is characterized by compact dimensions, ease of operation, energy independence, since the unit can operate not only from the mains, but also from a battery, resistance of the housing and structural elements to water ingress, absence of noise and vibration during work, and low cost.

Helpful advice! For home use, you can make such a pump for pumping water with your own hands.

12 Volt water pumps are characterized by compact size, energy independence and ease of operation

The productivity of the mini-pump is 15-25 l/min. The unit provides a liquid pressure of 20-40 mm of water. Art. The low-voltage pump can be operated at liquid temperatures from 10 to 80 degrees.

Centrifugal pumps

In this type of device, the main working element is the disk on which the blades are fixed. They are inclined in the direction opposite to the direction of movement. The blade is fixed on a shaft, which is driven by an electric motor. The design can use one or two wheels. In the second case, the blades connect them to each other.

The operating principle of a centrifugal pump is based on the fact that water enters the working chamber through the inlet pipe. The medium captured by the rotating blades begins to move with them. Centrifugal force moves water from the center of the wheel to the walls of the chamber, where increased pressure is created. Due to this, water is thrown out through the outlet. Due to the fact that the water is constantly moving, pumps of this type do not create pulsations in the water supply.

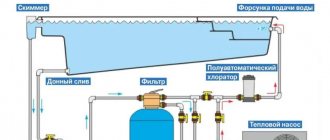

Using centrifugal pumps for domestic purposes allows you to perform various tasks. They are often used to extract water from a borehole or well. The water pumped out in this way can be used to arrange the water supply for the house, and can also be used for watering the site. Using centrifugal-type models, you can ensure the circulation of warm water in the heating system: due to the fact that the pumping centrifugal pump does not pulsate, air will not appear in the system. Various subtypes of such pumps can be used for pumping water from basements or swimming pools, for removing fecal matter, and also as drainage machines.

It is worth noting that simple pumps with a centrifugal system are designed for clean water without solid elements. Various subtypes allow you to work with contaminated environments.

Principle of operation

The owner of a pumping station, who independently installs and maintains the components, needs to know how a centrifugal pump works.

The design of a centrifugal pump includes an impeller with curved blades mounted on rolling or sliding bearings. The housing has a spiral configuration, a supply pipe and a pressure line flange are provided. Before starting, a portion of liquid is poured into the housing cavity to ensure further operation of the pump.

When the impeller rotates, the liquid in the pump crankcase is thrown by centrifugal acceleration to the periphery of the casing. Due to the resulting pressure difference, part of the liquid goes into the pressure line. Due to a decrease in the volume of liquid in the housing, a pressure drop occurs, which helps draw water from the container or well into the suction channel. The performance of the pump and the water pressure in the pressure line depend on the rotor speed.

Axial models

In devices of this type, centrifugal forces are completely absent, and the entire process occurs through the transfer of kinetic energy. In the working chamber, which has a bend, the blades are on the axis. It is located in the direction of the flow. Water moves through the chamber, the axis increases its speed and pressure. Due to this design, the requirements for their production are quite serious. Most often, such pumps are used as a ballast and control system in ships, floating docks and similar equipment.

The main task of such pumps is to pump fresh and salt water. Used for drainage, supply and purification of water. Axial pumps can be very compact in size and installed inside the water supply.

Pump for pumping water: characteristics of the unit

A water pump is a hydraulic unit that extracts, pumps and moves liquid horizontally or vertically. This occurs through the transformation of electrical energy into potential or kinetic energy. The internal structure of the unit depends on the method of energy conversion.

Pump performance is the volume of water that it can pump per unit of time.

Any autonomous or conventional electric water pump, regardless of the type of device, consists of a metal body, an impeller located on the shaft, seals, bearings, a guide device, an electric motor, a casing on it, suction and pressure pipes. The unit body is made of cast iron or steel. It has two holes. The bottom one is used for water intake, where the suction pipeline is connected through the inlet pipe, and the side one, where the pressure hose is fixed, is used for injection.

The main operating parameters of a mechanical water pump include power, pressure, and productivity. The first indicator directly determines the effective performance of the unit and indicates the amount of kW/h that the device will consume. The developed pressure determines the permissible distance over which liquid can be pumped. Here attention is paid to the length of the pressure pipeline.

The depth of liquid rise indicates from what level water can rise. The performance of the device determines the volume of water that the unit can pump per unit of time.

Vortex pumps

Vortex pumps have a similar structure to centrifugal pumps, only in them the water supply is carried out in such a way that when water enters the chamber, it moves tangentially relative to the periphery and moves to the center of the wheel, from where, under pressure and due to the movement of the blades, it again goes to the periphery, and from there discharged through the outlet pipe. The main difference is that with one revolution of the wheel with blades (impeller), the cycle of suction and expulsion of water occurs many times.

This design allows you to increase the pressure by 7 times even with a small amount of water - this is the fundamental difference between vortex pumps and centrifugal pumps. Just like centrifugal pumps, these models do not tolerate solid inclusions in water, and also cannot work with viscous liquids. However, they can be used to pump gasoline, various liquids containing gas or air, and aggressive substances. The downside is low efficiency.

Such pumps are used for different purposes and areas, but their installation is advisable if the amount of substance that needs to be worked with is small, but high pressure is required at the outlet. Compared to centrifugal models, these devices are quieter, smaller and cheaper.

Design features

On the modern market you can find household water pumps of various models, but they all work on a similar principle. The suction of water into the internal chamber of such a pump is carried out due to the rarefaction of air, which is created in it by the main working body of the device, and further expulsion of the liquid through the pressure pipe occurs due to an increase in its pressure. Screw and gear pumps operate on a different principle, in which the pumped liquid, entering the internal chamber, is captured by meshing gears or a screw and moves from the inlet to the pressure pipe.

The pressure with which the flow of liquid is pushed out of the internal chamber determines the pressure in the pipeline system. The latter should be sufficient to ensure the transportation of water over the required distance and its supply to all water intake points.

Submersible pumps for clean and dirty water, equipped with float switches

Classification by food type

All water pumps have a certain method of power - from electricity or from liquid fuel. In the latter case, they are necessarily equipped with an internal combustion engine. A mixture of gasoline and oil or diesel fuel is used as liquid fuel.

Gasoline models are cheaper and quieter. Diesel devices are fueled with diesel fuel. They are more expensive, but the fuel is cheaper. In addition, they are noisier.

Liquid fuel pumps are otherwise called motor pumps. Their main advantage is ease of use and mobility, that is, they can be used anywhere if there is no electricity.

Electric models use alternating current to operate. The owner of such a pump does not need to worry about the availability of fuel, but care must be taken to ensure the constant availability of electricity, which is not always convenient.

A short video tutorial on pump selection

When choosing an electric water pump for your home, cottage or garden, first of all consider its intended purpose. There is no ideal equipment for “everything”. Consider what main tasks the device will perform, whether it will only work to pump clean water or whether there is a possibility that it will have to lift water with sand and dirt.

When selecting a specific model, be sure to take into account the most important technical parameters: power, performance, efficiency, maximum pressure. If during the calculations you have doubts about their correctness, consult a specialist. As for brands of household water pumps, the brands Wilo, DAB, Gilex, and Belamos have proven themselves well. The market leader is the Grundfos brand.

- Author: irina-jakuschenko

Rate this article:

- 5

- 4

- 3

- 2

- 1

(6 votes, average: 3.8 out of 5)

Share with your friends!

Classification by liquid quality

Different types of pumps have different requirements for water purity. All devices can be divided into three types.

- For clean water. The content of solid particles in it should not exceed 150 grams per cubic meter. These models include surface pumps, as well as well and borehole pumps.

- For moderately polluted water. Insoluble inclusions from 150 to 200 grams per cubic meter. Drainage, circulation and self-priming types. Also some fountain models.

- For dirty water. Solids from 200 grams per cubic meter. Drainage and surface sewerage models.

Bends

Outlet is a part of the pump casing, which generally serves to collect the liquid medium leaving the channels of the pump impeller, convert the kinetic energy of the liquid into potential energy and supply the liquid to the next stage in a multistage pump or discharge it into the pressure pipeline. Bends are available in annular, spiral, and blade types, as well as composite ones.

The annular outlet consists of an annular channel with a constant or slightly increasing cross-sectional area (Fig. 28, a). Ring bends are used primarily in pumps pumping liquid with suspensions.

The spiral outlet is a channel with ever-increasing cross-sections and ending with a diffuser (Fig. 28, b). Such bends are most often used in single-stage pumps, but the possibility of their use in multi-stage pumps cannot be ruled out.

One of the main disadvantages of spiral bends is that in bends of this type, under off-design operating conditions, radial forces arise, leading to an increase in the deflection of the pump shaft in off-design mode. Thus, when the supply decreases, the spiral outlet acts as a diffuser, and when the supply increases, it acts as a confuser. In both cases, this leads to the fact that the velocity and pressure fields along the outlet section of the impeller cease to be axisymmetric.

To reduce the radial force, spiral bends are manufactured with a baffle. This type of bend is called a double spiral bend (Fig. 29).

A vane outlet (an outlet in the form of a guide vane) can be considered as a stationary circular grid located around the pump impeller and consisting of a series of channels formed by stationary blades. The vane outlet consists of two sections: an initial section with spiral channels and a final section with either diffuser channels (in a single-stage pump) or transfer channels (in a multi-stage pump).

Vane bends are used mainly in multistage pumps.

Large pumps sometimes use compound taps, consisting of a combination of a vane tap with either a volute tap or an annular tap.

The drainage has a significant impact on the efficiency of the pump. The more hydraulically perfect its channels are, the larger part of the dynamic pressure it converts into pressure. In this sense, spiral bends have an advantage over bladed bends; their channels compare favorably with the channels of bladed bends.

Classification by location

All pumps are also divided into submersible and external (the more common name is surface pumps). The first type is located directly in the water or partially in it. Models that are not completely submersible are called semi-submersible.

It is worth noting that there are several types of submersible pumps.

- Vibrating - here the work is based on an electromagnetic field and vibration of a special mechanism; these types of pumps require certain installation rules. In particular, there are strictly specified distances to the bottom.

- Centrifugal devices, which were discussed above.

All submersible pumps can have a motor that is already built into the housing, meaning it is underwater. For some models it is located on the surface.

The external pump is located directly next to the reservoir. In this case, the suction mechanism operates through a special hose. The further the pump is located from the water, the more powerful it should be.

Most often, surface pumps are used in dachas and suburban areas. They are highly economical and small in size, which makes them popular for home use. They can be equipped with automation, which makes them completely autonomous.

Advice! When using a remote ejector, you can extract water from an impressive depth.

Submersible pumps

Submersible pumps, among other things, are divided according to their purpose:

- borehole;

- wells;

- drainage;

- fecal.

Boreholes have an elongated shape and are used to extract water from wells. Compact dimensions allow it to be lowered into small-diameter wells, but production can be carried out from very great depths. They are distinguished by high operating power. Use only for lightly contaminated or completely clean water.

Wells are used to pump water from mines and wells. The main difference from borehole ones is their larger size and shallower immersion depth. They are quite powerful and can work with water containing silt, sand or clay. Quite quiet and does not vibrate.

The main task of drainage systems is to pump out contaminated water from basements, trenches, pits and other places. There are varieties with knives for chopping, as well as for working with lightly contaminated environments.

The fecal pump does not have significant differences from the drainage pumps, except that they are designed for heavily contaminated water with large solids (about 35 mm in diameter). They also have knives for grinding waste. Such pumps can be either submersible or external.

Surface pumps

The main difference between surface pumps is their location close to the water. They can be divided into several types:

- self-priming;

- automatic;

- pumping stations.

Self-priming pumps come in ejectorless and ejector types. In the first case, water is drawn in by the structure itself, in the second by creating a vacuum in the chamber. They are used for irrigation, delivery of drinking water or for domestic needs, as well as for collecting water from surface reservoirs (rivers, ponds). The water should be clean or slightly polluted.

Automatic pumps are provided with automation, which simplifies the process of use. There is no need to monitor the pump. Automatic pumps are powered by electricity. The machine itself can be installed directly in the model or as a separate system. The main task is to optimize use, as well as a protective function. For example, the device will stop working if the reservoir suddenly becomes shallow, the temperature of the pumped substance increases, or if there is a voltage drop in the network.

The pumping station consists of the pump itself, a check valve, a control system and a battery. Such a device has a rubber bulb installed inside a metal case. Water is pumped into the pear and air around it. A special sensor responds to changes in ambient pressure that occur as the bulb fills with water. When the pressure reaches its maximum, the sensor stops the water supply.

The ease of use of such units lies in their simplicity and functionality, the ability to be used during power outages. They can also provide water to several points at once.

Vibrating pumps for home and garden

For your home, cottage and garden, you can choose an electric vibration-type water pump. Its operating principle is based on the influence of an electromagnetic field created by a coil that draws in a metal core with a flexible diaphragm. By bending, the rubber diaphragm creates low pressure, due to which water is sucked into the hydraulic chamber. When the diaphragm returns to its place, the pressure increases and the valve closes the inlet, so the water is pushed out through the outlet. The constant movement of the diaphragm ensures uninterrupted pumping of water.

Vibrating pumps are used to organize watering and irrigation of plants. They are installed in autonomous water supply systems. A huge advantage of this design is the ability to pump contaminated water, which allows them to be used when pumping wells and boreholes for preventive cleaning. When working with dirty water, the performance of vibration pumps drops noticeably, but they are quite capable of cleaning the bottom of hydraulic structures. Another advantage of the design is its relatively low cost and reliability. The durability of the devices is ensured by a design in which there are no moving or rubbing parts.

If the diameter of the well is relatively large, then you can install a vibration pump, after putting rubber rings on it to “dampen” the vibration

Electric vibration pumps have as many disadvantages as advantages. Devices often malfunction due to power surges. If the home owner decides to install a vibration pump, he will additionally have to purchase a voltage stabilizer. Such pumps are successfully used for pumping water from wells, but it is not advisable to install them in wells, especially small ones, despite the ease of installation. Constant vibration negatively affects the casing structure, and sooner or later the pump will either break itself or destroy the production pipe.

It is not advisable to install the Rucheek pump in narrow casing pipes. This may result in unplanned pump repairs or even the drilling of a new well.

Criterias of choice

When choosing a submersible pump for a well, first of all, they proceed from the main parameter of the source - the volume of supply (flow rate); if official drilling was carried out, this indicator is indicated in the passport for the well.

It should be noted that the flow rate depends on the electric pump used, so if it suits the owners, you should choose a unit with the same value. In addition, the passport provides figures for the static and dynamic level, the height of the casing and its diameter.

When carrying out drilling operations independently, determining the flow rate is not difficult - the water raised by the pump is poured into a container of known volume and the time for filling it is counted.

Surface or submersible

Due to the short distance of the aquifer from the surface of the earth and the small diameter of the casing pipes in an Abyssinian or home-made well, surface-type units are used, the suction depth of which does not exceed 9 m. Also, surface pumps into a water well can be used in artesian or sandy sources, if they static and dynamic level less than 9 m.

Typically, external water intake equipment is located in a single block called a pumping station; it includes a surface centrifugal electric pump, automation elements (relays), control devices (pressure gauge) and an expansion tank (hydraulic accumulator).

Due to the high noise during operation, the selected surface station must be placed in the basement of the house or a coffered pit; the advantages include easy access to the equipment at any convenient time.

Deep centrifugal pump for a well - design using the example of Pedrollo

Submersible pumps are used in cases where the water surface is located at a great depth; compared to surface models, they have higher characteristics, allowing several houses to be supplied with water from a high-performance artesian well, even in domestic use. They are more difficult to install and immerse in the well; this requires special heads and adapters. Since the well pump is out of sight, maintenance and monitoring of its operation is difficult.

In the absence of washing water, the submersible pump fails; if the system does not have an idle relay installed or the unit does not contain built-in protection against winding overheating, any drop in the water level below the water suction holes of the filter will lead to burnout of the electric motor.

Pump performance - determination method

As noted earlier, surface models are more effective when used at small distances of the water surface from the surface of the earth; such pumping equipment is better suited to independently constructed wells. When drilling wells yourself, there is no data on the speed at which the source is filled with water, but based on this information, the desired model of the future pump is selected. In this case, you cannot cope without an electric pump that takes water from the source, so you will have to temporarily borrow or rent it.

Vibrating submersible pump for a well - device and appearance

When determining the flow rate of a source with a surface electric pump, it is placed as close as possible to the well and the pressure pipe is immersed in water; at the output of the electric pump, the water is poured into a container of known volume, while measuring the time of its filling.

Let's say an ordinary 20 liter canister is filled in 60 seconds, converting this time into hours, we get a flow rate of 1200 liters per hour, which corresponds to the standard counting units of 1.2 cubic meters per hour. If after some time (1 hour) the water in the source drops below the level of the suction pipe and does not appear at the outlet, the electric pump is turned off and the well is given time to replenish its water reserves. A shut-off valve is installed at the outlet of the pipe from the pump and after some time the electric pump is turned on again, reducing the water flow with a tap, the presence of which is also monitored for an hour.

Thus, by means of several experimental intakes of different volumes of water, the amount of liquid per hour that can be pumped out by a well pump is determined; the technique can also be used in the case of determining the flow rate of a well with a submersible electric pump.

Lifting height - what factors to consider

A water pump in a water supply system must perform three tasks: lift water from a source, deliver it through pipes to the consumer, overcoming their hydraulic resistance, and provide the system with a given pressure for the operation of automation and home appliances (washing machines and dishwashers). It is these components that make up the formula for calculating water pressure, which will be discussed below.

Screw deep well pump - device

Immersion depth

The depth of immersion under the water surface is a passport parameter taken into account when installing a submersible electric pump; surface types are located on the ground and the data is not included in their technical characteristics. To determine the immersion depth that the selected unit should have, the static and dynamic levels are measured.

The static level is the distance from the surface of the earth to the water surface in a calm state of the source, the dynamic level is determined when an electric pump operates at depth for an hour, it is also equal to the distance from the surface of the earth to the water surface.

All measurements of water levels are made using a long dry rope with a weight, it is lowered into the well until a splash sound is heard and then the distance between the edge of the wet area and the surface of the earth is measured.

The selected submersible model must have a immersion depth in its passport specifications equal to the distance between the static and dynamic levels with a margin of 3–5 meters. This will allow the electric pump to be located far enough from the silted well bottom when using sand wells and thus improve the quality of the water taken.

Also, when the water level drops in dry weather or when the source silts up, a reserve of several meters will ensure uninterrupted operation of the electric pump. Another advantage of placing the electric pump further away from the bottom is saving money on materials and choosing a cheaper model with fewer technical requirements.

Casing parameters

Well diameter

The borehole diameter plays an important role in determining the dimensional parameters of the selected unit; it must fit into the channel with a small gap between the pipe walls. The standard diameter of manufactured submersible electric pumps is about 75 or 100 mm; for these sizes, taking into account the wall thickness, casing columns with an outer diameter of 90, 113 and 125 mm are suitable.

What to look for when purchasing

When communicating with a specialist, it is worth indicating the type of work for which you are going to purchase a pump. Draining the ground before laying the foundation of a house and installing a water supply to this house are completely different tasks that require different techniques. In this case, it is not necessary to buy both pumps - if the work is one-time, one of them can be rented.

Next you need to compare prices. Do not choose the cheapest models - as a rule, they either have little power or a short service life. Contrary to the prevailing stereotype, the country of manufacture does not greatly affect the quality of the product: many European brands actually produce spare parts in China, and the country of assembly can be any. At the same time, the price for a well-known brand is much higher, and the quality is approximately on the same level as a less advertised company.

To make it easier to make a choice, when purchasing, pay attention to the following characteristics:

- volume of fluid moved;

- pressure;

- power;

- efficiency;

- working environment parameters.

To ensure that the equipment lasts longer, we advise you to carefully read the instructions and guarantees provided by the store. Not all pumps are designed to operate without interruptions and maintenance, and if used incorrectly, the seller has the right to refuse repairs. If, despite following all the recommendations, a breakdown still occurs, contact the service center.

How to bring water from a well into a house with a deep pump

Having purchased a suitable pump, you can begin arranging a water supply from a water source. This will require pipes through which water from the well will flow into the house. The diameter of the pipes should be 25–32 mm. Experts advise buying polymer products, as they do not corrode and are easy to bend. Further, during the work process, the pipes will be installed in the soil to a depth of 30–50 cm. To arrange water with your own hands, you will also need a septic tank. To make it easier to maintain, you will need to purchase a drainage pump.

Having prepared everything you need, you can start working. The algorithm of actions is as follows:

- First of all, you need to equip the pipe coming out of the well with a head;

- Next, you need to install the caisson. To do this, you will need to dig a hole next to the well and place a plastic container inside it;

- After this, you need to install the pump in the well. To do this, you need to pull a hose onto its nozzle and secure it securely with a metal clamp. After this, the hose, cable and safety rope are tied with electrical tape in increments of 1.2 m. Then the pump body is tied with a steel cable, and the unit itself is lowered into the water. During installation, the device should not swing, otherwise hitting the wall will cause pump malfunctions;

- Next, you need to connect the hose to the underground pipes. All joints must be treated with sealant and tied with FUM tape;

- Before burying dug trenches, the water supply should be checked. To do this, you need to start the engine for a while and observe the amount of water flowing from the pipes. If the pump performance does not decrease, you can dig trenches.

It is very important not to damage the unit while lowering it into the well. This must be done very slowly and carefully. Otherwise, an expensive repair of the device may be required, or a complete replacement of the deep-well pump.

Connection and service of a well pump.

Before lowering it into the well, the Aquarius pump must be prepared:

– The pressure pipe must be connected. The type of pipe to be connected depends on the needs for which the Aquarius pump is planned to be used. You can use an irrigation hose if the well pump device will be used for irrigation or water intake, or if it is planned to be used for work in conjunction with a hydraulic accumulator in a stationary installation - a metal or plastic pipe.

– Installation of a check valve. When connecting a pump that operates in a closed pressure water supply system, it is necessary to connect a check valve. A check valve is not installed during production. There are two connection methods: by inserting into a pipe at a distance of less than 1 m from the outlet pipe or by installing the valve directly into the pipe. According to experts, the best choice is a valve with a brass seat.

– Attaching the cable. The cable is passed through special slots on the body and securely fastened. The cable can be used both from nylon and steel. It is strictly forbidden to lift or lower the pump by the wire. From practical experience it follows that it is best to secure the wire in the pressure pipe using brackets designed for this purpose - this will make lowering and raising the device easier and virtually eliminate the possibility of mechanical damage. After this, the well pump device is connected to the outlet.

– the device is carefully lowered into the well under strict control over the degree of tension of the pressure hose and electrical cord. The device is secured at the required depth with a cable. The pump can be used.

Even taking into account the high reliability of the Aquarius pump and the fact that it can operate uninterruptedly for many years, it is recommended to remove it from the well twice a year and inspect it for damage. Examine it from the outside. It is unacceptable for the engine axis to jam during rotation, which should be light and soft . If no jamming of the axle is detected and the device uninterruptedly pumps water at the required pressure, it should be installed in its place.

If there are any concerns about the correct operation of the device, the examination should be continued. The design of the well pump provides for the possibility of systematic inspection and, if necessary, replacement of rotation bearings. It is recommended to inspect the condition of these parts, the oil seal and check the oil level. If this is necessary, it is worth changing the oil seals and bearings, and adding oil to the required level.

It is worth looking at the motor windings and determining if there is any damage or signs of overheating. Disassembling an engine is a delicate matter: after all, the wire insulation becomes brittle and easily damaged after some time. The pumping part does not require special maintenance, but if the pressure of the device drops significantly, it would not hurt to change the impellers - perhaps the reason is their wear.

Where can I buy?

To find a supplier of pumping equipment, you can safely look on the Internet. Knowing the desired indicators, it is not difficult to choose a brand and model, as well as get advice from professionals. For this purpose, it is better to consider large firms or companies that are official dealers. Moreover, they don’t take money for it. After you decide on the brand and model, you can look for a selling organization with the best price, location, delivery, installation capabilities, warranty and post-warranty service.

The choice of offers is huge: from spontaneous markets to official representative offices of famous brands. It is worth remembering that chasing the best price is not always justified, since the time will come when you will be faced with issues of warranty and post-warranty service.

Let you always have clean and tasty water, and in sufficient quantity. Clean water for you, comfortable living and coziness in your home.

Overview of borehole pumps for water supply

Deep well pumps must be selected based on a combination of parameters. This equipment is purchased for many years, so the main requirement is its high quality. The performance characteristics of the best models of borehole pumps for water supply are presented in the following table.

| Table of characteristics of deep-well pumps | |||||

| Pump name | Diameter, inches | Productivity, m³/hour | Head up to, m | Price, % | Country of manufacture |

| Rucheek-1 | 4 | 1,0 | 60 | 100 | Belarus |

| Unipump | 4 | 1,8-4,8 | 52 | 400 | China, Russia |

| Belamos TF | 3 | 1-3,3 | 60 | 720 | |

| Aquario | 3 | 1,5 | 60 | 1120 | Italy, Russia |

| ESPA | 4 | 4,2 | 60 | 1240 | Spain |

| Pedrollo | 9,0 | 135 | 1400 | Italy | |

| TWU | 3 | 3,8 | 70 | 1400 | Germany |

| Lowara | 4 | 1,4 | 105 | 1440 | Italy |

| Gardena | 4 | 1,5 | 60 | 1560 | Germany |

| Grundfos | 3 | 1,5 | 80 | 2000 | Denmark |

| Wilo | 3 | 2,6 | 88 | 2000 | Germany |

We hope that the recommendations outlined above will help you purchase the necessary equipment for pumping water. The following video clearly demonstrates the rules for selecting and installing a well pump.