Metal tiles are one of the most popular roofing materials today. A special feature of this product is the ease of installation work; in addition, no special construction tools or skills are required. If we take into account the cost and service life of a roof made of metal tiles, then this option is considered optimal for roofing. During installation, it is important not only to take into account the technical characteristics and quality of the finished product, but to choose the color of the metal tile that would match the overall design.

Features of the material

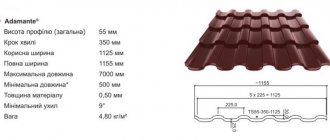

Metal tiles are steel sheets, the thickness of which varies from 0.35 mm to 0.7 mm. Moreover, the rigidity and stability of the roof directly depends on this indicator. The sheets are galvanized on both sides, the outer side is coated with a special compound, polyester or plastisol. The dimensions of metal roofing tiles are as follows: the width of the sheet is usually 1 m, the length ranges from 1 m to 8 m.

The main advantages of the roofing material in question include:

- light weight (no more than 6 kg per square meter);

- ability to easily withstand temperature changes;

- ease of replacing damaged elements;

- resistance to corrosion (subject to certain conditions);

- reliability and long-term operation (up to 50 years);

- relatively low cost;

- color variety.

Tile thickness

According to existing standards, the thickness is approximately 0.6 mm.

For production, steel is taken, which is produced by the roll method. The future sheet is formed on special equipment.

The entire product must have the same thickness.

Due to the absence of thickness deviations from the norm, the product acquires incredible strength. What makes the tiles a resistant material to any external environmental factors.

Manufacturers producing tiles are subject to strict control. To avoid problems with the thickness of the product, the equipment is replaced immediately after it has worn out.

Arrangement rules

When working independently on creating a roof, you must strictly follow the technology for installing a metal tile roof. An inclination angle of at least 14 degrees is allowed.

When installing a gable roof, installation begins from the lower corner of the left side. The next sheet is superimposed on the previous one with an overlap of one wave. If a hip roof is meant, then work begins from the highest point, gradually descending along opposite sides.

The last metal tile sheets must be hung over the final sheathing board by about 5 centimeters. They are fastened with special self-tapping screws of the appropriate color, which have rubberized gaskets. The ridge is covered with special seals, on top of which a metal ridge element is installed.

A variety of additional roofing elements creates gaps that need to be sealed. For these purposes, silicone-based sealant and special sealing tapes are used.

The under-roof space is where cold prevails and condensation can form. Therefore, it is necessary to make a high-quality roofing cake, taking care of the proper vapor and waterproofing components, as well as ventilation.

Transportation and selection of tiles

When delivering such material, certain requirements must be met:

- When loading, gangways are used;

- transport must have a luggage compartment no less than the length of the tile sheet;

- transfer of sheets is possible only in a vertical position;

- store in a dry place and make a small podium under the tiles.

The choice should be made on the material that you need. Based on the characteristics that each type of Monterrey metal tile has. Then you will purchase a quality product that will last for many years.

Tools

For work you will need: a screwdriver with a bat for a roofing screw, a cutting tool, a special strip to maintain the same distance between the sheathing, a tape measure, a tapping cord, a marker, sealant, and a hammer.

Professionals do not recommend using a grinder for cutting sheets, as it will burn the edges of the cut and may leave traces of hot scale on the surface. This will subsequently lead to metal corrosion.

Greens are oxygen

The biggest problem of modern cities is air pollution. Environmentalists believe that one way out of this situation is the arrangement of so-called green surfaces.

Looking at photographs of green roofs that have begun to appear in megacities around the world, you understand that the arrangement of recreational areas is not only a matter of beauty, but also of one’s own health.

Warm roofing cake

The layers of the roofing pie must be arranged in strict sequence. The composition of a warm roof is represented by: a rafter system, a vapor barrier film, a thermal insulation layer, waterproofing, counter-lattice, sheathing and, finally, the metal tile itself.

Rafters and additional reinforcement of their load-bearing capacity make up the roof frame. The vapor barrier releases steam from the room; it is attached to the inside of the sheathing boards. Thermal insulation is placed between the rafters, for example, it can be mineral wool.

Waterproofing the roof under metal tiles is necessary to prevent the ingress of condensation that falls on the back side of the metal. The counter-lattice presses the waterproofing layer against the rafters and creates the necessary ventilation gap between the waterproofing and the sheathing. The sheathing boards are nailed to the counter-lattice, and metal tiles are attached to them using self-tapping screws.

Stages of work

Roofing work with metal tiles consists of several stages. To avoid mistakes, it is recommended to follow their sequence. The main stages are as follows:

- preparatory work;

- checking the rafter system;

- calculations and purchase of materials and additional parts;

- preparation of instruments;

- installation work.

Next, we will consider each stage in more detail.

Preparatory work

The following tools will be useful for installation:

- roulette;

- hammer;

- screwdriver;

- level about 3 meters high;

- metal scissors.

It is recommended to prepare tools in advance Source krovlya-yuga.ru

Before laying metal tiles on the roof, it is necessary to make calculations and prepare sufficient quantities of material. It is also necessary to consider methods for sealing gaps between sheets.

Rafter system for metal tiles

The level of strength of the roof, as well as the level of strength of the structure itself, depends on how correctly the rafter system is constructed. At this stage, the task consists of two stages: make the correct calculations and install the structure. The importance of correct calculations is difficult to overestimate, therefore, they must be treated with sufficient attention.

As already mentioned, a gable rafter system is ideal for metal tiles. To construct such a support, bars of different lengths are used. The angle of inclination of the bars should vary between 15-30°. These are the optimal values.

The next important nuance of calculation is the pitch of the rafter system. The pitch is the distance between two rafter beams. The optimal pitch value for metal tiles should be in the range of 0.6 - 1.2 meters.

The main elements of the rafters are as follows:

- rafter legs;

- racks;

- Mauerlat.

Fastening of various parts of the rafters is carried out using metal strips - tires.

Rafter system for metal tiles Source plotnik.technology

Calculations

Before laying metal tiles on the rafter system, it is important to make accurate calculations. Once the distance between the rafters has been determined, you can proceed to calculating the required material. It is recommended to adhere to the following rules:

- Calculate the length of the roof slope. Measurements should be taken along the roof eaves.

- Counting the number and length of valleys and skates.

- Consider and introduce a drainage system into the plan.

The calculation is made based on the data received. You can calculate it yourself or contact specialized companies. Specialists perform calculations using special computer programs, which ensures maximum accuracy.

It is important to purchase materials in sufficient quantities to complete all roofing work in one stage. If there are interruptions in construction, the unfinished roof will be vulnerable to weather conditions.

When purchasing material, the physical and technical parameters of the material are taken into account.

Calculation must be made before purchasing the material Source lalafo.com

See also: Catalog of companies that specialize in roofing work

Installation of additional systems

One of the important points about how to properly lay metal tiles on a roof is to consider protection from moisture and hail impacts. Protection from rainwater is carried out by installing a waterproofing film or membrane. The selected material should be laid over the rafter system and secured at the edges with a stapler.

It is also important to consider the thermal insulation system. Usually it is carried out in cells that are formed at the corners of the intersection of the beams.

Valleys and their features

The most painstaking part of the work is installing the roof valley. Valleys are an intersection point between two slopes. They are also commonly called gutters or adjacent strips. The difficulty lies in the susceptibility of this area to leaks.

It is customary to distinguish between upper and lower valley structures. The lower structure is responsible for drainage and tightness; upper valleys are often installed for aesthetic reasons.

This is what valleys look like for metal tiles Source stroidom-online.ru

Features of the arrangement are as follows:

- Upper valleys do not require a special approach, since their main function is the aesthetic camouflage of metal tile sections. Installation is also simple: they are screwed to the wave crests using self-tapping screws. Typically, for the upper ends, a material of the same color as the main color is chosen.

- When arranging the lower ends, you can use additional elements for waterproofing. For example, these could be flexible bituminous materials. It is recommended to make the lathing about 20 cm wide on both sides of the junction. The structure is also mounted with special screws or special metal strips.

Work at this stage requires maximum care, since valley defects may not be noticeable during the work process. If the roof is made with low-quality valleys, then the water may not show itself for a long time. But during this time the liquid will negatively affect the rafter system.

More valleys for metal tiles Source staltd.ru

Installation of chimneys

Another important part of the task of how to properly lay metal tiles is the arrangement of chimneys. Here it is also necessary to organize a water protection system. For these purposes, it is recommended to make two protective layers:

- In addition to protecting against moisture, the upper structure also serves a decorative function. To do this, metal strips should be installed in chimneys in grooves. This design allows liquid to flow from the bar to the common surface.

- It is recommended to make the lower part from flexible materials. This part allows water to drain into a long metal plate connected to the valleys.

Horse

A roof ridge is a horizontal rib installed at the top joint of the sheets. Shapes can be different: simple geometric or convex. The skates are installed using long self-tapping screws. The dimensions of the hardware should be 2-3 cm greater than the wave height of the coating. Roofing ridges are sold ready-made.

Skates for metal tiles Source marketudachi.ru

Junction strips

Another point that should be considered before installing metal tiles is the planks adjacent to the wall. They are installed at the joints between the wall and the creeping edges of the rafter system. They are bent metal strips of the same color as the main part of the metal tile.

If the gaps between the wall and the rafter system are large, then it is recommended to use additional seals made of foam rubber or rubber. This solution provides additional sealing and reliable fixation of the slats. The strips are fixed to the ridges of the metal tile sheets.

Snow guards

In some areas, due to climatic conditions, it will be necessary to install snow guards on the roof. Snow caps tend to form even on completely smooth roofs. When the thickness of a snow layer reaches a certain height, there is a risk of collapse. When the snow begins to thaw, icicles become a risk factor. In such cases, snow holders help. They do not allow the snow layer to descend sharply.

Snow holders look like this Source tsmnn.ru

These structures are necessary to keep snow from falling off the roof. There are three types:

- tubular;

- lattice type;

- plate type.

Plate-type snow holders are recommended if climatic conditions do not require an abundance of snow. Such parts are easily screwed to metal ridges and are not designed for heavy loads.

Large loads are well withstood by tubular and lattice snow retainers. They are fixed to the sheathing of the beam system. The need for snow holders is determined based on climatic conditions and taking into account the angle of inclination of the roof slopes.

When installing snow holders on metal tiles, the first step is to install the brackets. The distance between them should be at least 30 cm. The line of fastening of the brackets should be along the sheathing bars, which will take the load. Gaskets are placed on the upper and lower holes.

Cold roofing pie

A waterproofing layer is spread along the rafter legs, which is pre-fixed using a construction stapler. Then the counter-lattice is stuffed. The sheathing boards are attached to it, then the metal goes on.

As in the case of a warm pie, in this case it is also necessary to ensure proper ventilation of the metal tile roof. It is achieved thanks to the counter-lattice, which provides a gap between the waterproofing film and the sheathing boards.

For the roofing pie under consideration, an additional vapor barrier layer is not required. The technology itself is used extremely rarely, since a roof without insulation produces large heat losses and does not cope well with noise. It is possible to insulate the ceiling, which serves as the ceiling in the house.

What color of metal tiles to choose

Due to the fact that the color palette of metal tiles is quite wide, each potential consumer will be able to choose exactly the shade for arranging the roof that best suits the design. As practice shows, psychologists have long proven that colors can have a fairly strong effect on the subconscious and human psyche.

If you approach this matter responsibly, the color of the metal tiles intended for roof decoration will have a beneficial effect on the emotional component:

- Blue, cobalt, ultramarine - these colors symbolize inner harmony and wisdom; as practice shows, such a choice allows you to relax. Such options are chosen by purposeful and selfless people. At night, with the right lighting, the roof looks quite advantageous.

- Cherry, red wine - metal tiles in a similar design were previously preferred by people from the upper strata of society. Such colors are able to convey the temperament, strength and power of the owner of the living space. Many psychologists argue that such options can develop self-confidence.

- Red-brown, terracotta - at the moment, metal tiles of these colors occupy a leading position. This is due to the fact that this design closely resembles natural products made from clay. The ideal option is a combination of beige, sand and pale yellow tones on the roof. These color solutions are a symbol of stability, prosperity, and can have a significant impact on active actions and communication.

- Green, emerald - these colors are natural. Metal roof tiles in this design are a symbol of calm, freshness, and balance. The green color palette can relax emotionally, has a beneficial effect on the nervous system, and brings harmony and understanding to the home. According to psychologists, people who prefer such metal tiles are sociable, friendly to others, they are quite calm and balanced.

- Gray and graphite are colors that symbolize justice and restraint of character. Gray can have an impact on intellectual work; in addition, this option is universal; if necessary, it can be combined with any other tones on the roof.

Before choosing any option, many experts recommend paying attention to the overall design. This is due to the fact that the roof must fit harmoniously.

Attention! Today, metal roofing tiles in chocolate, red-brown and dark green shades are popular.

Installation of the valley

The planks are fastened with an overlap of 20-40 cm. In this case, it is necessary to move from the cornice to the ridge. The end of the lower cornice strip is formed under the side. Near the ridge, a seal is made on the last strip.

Sheets of metal tiles suitable for the valley are cut approximately 7 cm from the axis of the laid plank. The valley itself is fixed with self-tapping screws, the cut edge of the metal tile is attached at the points of contact with the strip.

It is possible to decorate the edges of the cut metal tile sheet using special overlays. The latter are laid starting from the bottom of the roof, the overlap should be approximately 10 cm. The overlays prevent snow from blowing under the sheet cuts and make it easier for water to roll into the valley.

Video description

This video shows a detailed description of the installation process:

- Attaching the ridge strip

Fixation is carried out along the ridges through one wave. Here you will need long screws.

- Installing a decorative end strip

If installation of snow holders is planned, then they are installed at this stage. Depending on weather conditions, several types of such systems can be used. It is important to take care of the reliability of their fixation. If the fixation is not reliable, then the parts may break off under the pressure of snow and damage the roof, which will require expensive repairs. These nuances should be taken into account at the stage of learning how to properly lay metal tiles.

The nuances of finishing a chimney pipe

After installing the waterproofing, a special gutter is installed around the pipe and on the entire surface of the slope, which will serve as a water drain.

Interior doors in the house - which ones to choose? Review of the best models of 2022. 125 photos of new designs- Entrance doors to the house - which ones to choose? Review of the best models of 2022, design examples + 120 photos

- 8 by 8 house layout - the best design projects of 2022. Instructions for beginners + 100 design photos

The entire design requires compliance with some general rules:

- fixing the apron involves the use of a sealant;

- the apron itself should cover the top of the wave of the metal tile sheet;

- The inner apron is attached first and fits into the installed gutter, followed by the outer one.

A properly installed metal roof is strong and durable. If you follow the technology for laying sheets, as well as arranging the entire roofing structure, including insulation, you can get an excellent roof over your head. And your photo of a metal tile roof, posted online, will help novice builders easily cope with this stage of building their own home.

Photo of colors of metal roof tiles

During the construction process, you can get lost in the variety of colors. In addition, looking at the finished product, it is quite difficult to understand exactly how it will look on the roof of the building. In this case, an excellent option is to study photos with the colors of metal tiles.

Benefit

The National Geographic channel devoted a series of programs to the benefits of eco-roofs. Among the positive aspects the following were noted:

- Birds that seemed to have left them forever began to return to the cities;

- greenery has ennobled the appearance of neighborhoods with reinforced concrete buildings;

- residents of houses with green roofs began to use them as greenhouses and provide themselves with fresh herbs and vegetables;

- The roofs of houses have become a place for walking and relaxing in the fresh air in stuffy and polluted cities.

Modern wonder of the world

The use of new technology makes it possible to build something similar to the gardens of the mythical Semiramis.

Today, green roof siding has become very popular, which has a number of advantages:

- tightly covers the roof area with vegetation and protects the roof from high or low temperatures, damage and moisture;

- green spaces retain up to a quarter of precipitation using them for irrigation;

- turf and soil act as thermal and noise insulation, protecting the residents of the house from city sounds and maintaining a comfortable temperature inside the building.

The most important advantage of environmentally friendly roofs is their ability to create additional space for recreation, free from harmful substances, which is extremely important in modern cities.