Preserving a crop is sometimes more difficult than growing it. A generally accessible and virtually maintenance-free means for this is the cellar. When built separately, it is also the least labor-intensive and cost-intensive compared to other types of storage for agricultural products, except for pile and underground. But a cellar in an individual household is optimal in many respects:

- Only 1-3 types of root vegetables can be stored in a pile, and in the cellar everything that they eat themselves and keep for sale, from potatoes to delicious smoked meats.

- The loss of goods stored in the cellar is much less than in the pile.

- The pile must be disassembled as soon as the heat has set in, otherwise it will all rot. In a well-equipped cellar, fruits and herbs can be kept fresh until summer, and root vegetables can be kept fresh until the next harvest.

- The volume of excavation, construction and installation work during the construction of a cellar is much less than that of bunker-type storage facilities.

- When building a cellar, you can do without expensive materials and complex technologies - a novice builder can make a good cellar with his own hands using scrap materials.

- The labor intensity of the cellar is quite high, but comparable to laying a pile and much less than for bunker storages. Additionally, the cellar is built once, but the pile needs to be folded/disassembled annually.

- Compared to an underground cellar, a properly constructed cellar is better ventilated, which reduces the likelihood of rotting to an insignificant amount, and is poorly accessible to pest animals.

- The cellar does not require a constant power supply, filling with preservative gas, etc. costly receipts from outside.

- The cellar, if necessary, without any alteration, can be converted into a storage shed for storing large quantities of fruits and vegetables.

- The allocation of land for the cellar is minimal, even zero, as for bunkers.

- The cellar fits quite easily into the landscape design of the site, see fig. Experienced and knowledgeable builders even manage to combine a cellar with a pond, right pos. right there.

- The specific microclimate of the cellar gives some products a special quality.

Cellars on site

You should dwell on the last 2 points. Firstly, you can build a pond in a cellar only if you are a builder and an ace hydraulic builder, because... In fact, having a cellar near bodies of water is strictly contraindicated. True, in our time the trick with a pond can be accomplished by a savvy amateur, if the pond is in a ready-made fiberglass or carbon bowl and is equipped with an overflow. But digging a pond near the cellar will yield a lot of extra land; then you can build an ice cellar, see below, in which apples and cabbage will last until the new harvest.

Secondly, a person completely devoid of the makings of a taster, when tasting it at the market, can easily distinguish jarred cucumbers or sauerkraut from barrel ones, in favor of the latter. But, if you give him a taste of tub-and-barrel pickles, not only vegetables, but also mushrooms, meat, fish, lard, aged in the cellar and home-basement, then he will also easily give preference to cellar ones. And smoked meats stored in the cellar acquire a particularly delicate taste and aroma.

Thirdly, only in the cellar (see below) do homemade kvass, syta, intoxicated honey and fruit and berry alcoholic drinks: liqueurs, beer, etc. ripen properly. And grape wine materials (wine, cognac) generally reach the required level condition only in the cellar with special conditions; We will also touch upon wine and cognac cellars in the course of our presentation.

What kind of cellar to build?

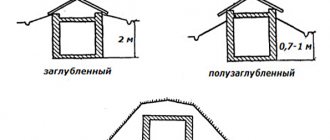

In any climate zone of the temperate zone it is possible to build a cellar of any of the 3 types according to the degree of depth: non-buried, pos. 1 in Fig. , semi-recessed, pos. 2, and recessed.

Types of deepening cellars

As for materials, the structure (box, chamber) of the cellar can be concrete, stone (brick), wood or earthen. We will return to the choice of material when we talk about construction itself, but for now please note: a cellar of any type must be surrounded by a drainage ditch with free flow. A damp cellar is not a cellar, but a rotten heap.

On the ground

A non-buried cellar is the least labor-intensive, but it “feels” soil movements well and stably maintains only the average seasonal temperature, i.e. It can freeze in winter and heat up in summer. The temperature in it can be brought to the average annual temperature (5-15 degrees within the Central Zone of the Russian Federation) by powerful earthen backfill. This execution is possible if there is a lot of soil left from other construction work, but then a larger land allocation will be required. A typical diagram of a non-buried cellar is shown in Fig. Mainly root vegetables are stored in it until spring or for winter sale. It’s easy to build a glacier in a non-buried cellar, because... drainage of melt water does not cause difficulties. In this case, you can store shelf-stable fruits: quinces, winter varieties of apples and pears until the new harvest. Material for construction – preferably wood or concrete, because the brick chamber may crack when the soil moves.

Construction of a non-buried cellar

About the vestibule

The risk of the cellar heating up can be reduced or completely eliminated by equipping it with a vestibule with 2 tight doors. This is how they most often build; a cellar without a vestibule is, in general, a construction hack. The exception is cellars in very cold regions with short summers, where the cellar is more likely to freeze than warm up. The vestibule is made inclined inward, then cold air will not come out of it spontaneously, and warm air will not flow in. But in a non-deep cellar, like it or not, the vestibule will be horizontal, this is another disadvantage.

In the ground

Construction of a semi-buried cellar

How a semi-buried cellar is constructed is shown in Fig. on right. In the ground it sits above the standard freezing depth (NFD) in the area. This allows you to maintain the average annual temperature in the chamber almost all year round; at the height of summer it rises slightly. You can store everything in a semi-buried cellar, the allocation of land for it is close to minimal, and the excavated soil is almost always enough for sufficiently effective backfilling, so it is preferable to build a semi-buried cellar in the country.

Due to its depth and the presence of a slightly heaving cushion around the entire chamber, a semi-buried cellar is little sensitive to soil movements and can be built from any materials suitable for a cellar. As a result, the semi-buried cellar comes in the greatest number of varieties. Unfortunately, it is only possible to supply a semi-buried cellar with a glacier if there is a drainage system on the site, because... draining melt water into periodically freezing soil can cause an emergency.

Dugouts

Cellar hut

Earthen cellars are very cheap: construction requires very little material, and the appearance fits perfectly into the country landscape, see fig. on right. The structure of an earthen cellar is shown in Fig. below. Depending on the nature of the continental soil (see below), the slopes of the chamber are sheathed with boards; perhaps along stakes driven into the ground, or left bare. The floor will be filled with clay that has been dug from the surrounding areas. It is also advisable to cover the roof with sand from the surrounding area, on top of it with excavated soil, and also lay excavated turf over it. The upper structure of such a cellar will also be an excellent cellar.

Construction of an earthen cellar with a cellar

Storehouses

Storage sheds are earthen cellars of shallower depth, without a top structure and with a thicker earthen backfill. Storage sheds are used to store fruits, vegetables and root vegetables for winter and spring sales, because... In the summer heat, they often warm up. Up to 8-10 types of products that are compatible during storage are loaded into bins. In a large storehouse for 1-2 types of root crops, they are sometimes piled on the floor.

Construction of large and small warehouses

A device large and small, with a camera 2-3 times narrower, is shown in Fig. The length of the chamber is practically limited by the size of the storage area. Ventilation of the warehouse is always exhaust and, highly desirable, with a fistula and catcher umbrellas over the bins, see below. When storing several types of products, their bins are each equipped with its own hood. The length of the support posts is 1.2-1.8 m, depending on the thickness of their logs or beams, 150-250 mm, respectively.

Cellar on the slope

Construction of a cellar on a slope

An earthen cellar on a slope is very effective, see fig. on right. To be able to build it, the continental soil must be non-slipping, clayey or loamy, and dry. Advantages of a dugout cellar on a slope:

- Minimum consumption of labor and materials.

- Almost insensitive to ground movements.

- It is possible to construct a glacier, because drainage of melt water is simple.

- A sloping ceiling with a hood at the ridge allows you to store a variety of products, because... Gases released by vegetables and fruits during storage are lighter than air. In fact, the ceiling of the cellar on the slope is one large umbrella-catcher over all the bins at once.

Note: the construction of any earthen cellar is possible only if there is at least 1.7 m from the bottom of the chamber to the groundwater during the period of its highest standing (see below).

Underground

Bottle cellar

The deep cellar goes into the ground below the NGP, so the average annual temperature in the chamber is stable. It is possible to reduce it to almost zero with a glacier, because... melt water can be drained into permeable, non-freezing soil. This is almost a bunker, only without a layer of soil above the structure. A deep cellar is very expensive and labor-intensive and, unlike a bunker, takes land away from economic use, which is why they are almost never built in the Middle Zone. However, in the southern regions with Mediterranean-type winters, you can sometimes find buried bottle cellars or tandoor cellars, see fig. They are built with adobe (in dry soil), brick or rubble. Thanks to the side sand filling and the upper clay castle, the temperature in the bottle cellar is kept 5-7 degrees below the annual average, i.e. up to 15 degrees. This is enough to store vegetables until spring, and melons and watermelons until the New Year.

Preparing the foundation pit

After preparation, you can start digging a pit. To do this, vegetation, stones and debris are removed from the area. Markings are applied and a hole is dug. Next, the walls of the pit must be leveled manually using a shovel.

It is worth noting that when determining the depth of the pit, it is necessary to take into account the space intended for the entrance, stairs and shelving.

- We buy and install an air conditioner

- Do-it-yourself windmill - the best ideas and instructions for building decorative windmills in the garden and on the site (105 photos)

Do-it-yourself walk-behind tractor - how to make a simple and reliable homemade walk-behind tractor for farming (105 photos)

Also, when building a brick cellar, you need to make allowance for the width of the walls. The bottom of the pit requires compaction. Next, it needs to be covered with gravel and sand.

About the cellar

The cellar is a wooden upper structure of the cellar, a kind of hut above the cell. Nowadays, a real log cellar can only be seen in an open-air museum (on the left in the figure), but in vain. Firstly, it serves as a thermal damper and stabilizes the temperature in the cellar at the average annual level with a much smaller depth of the chamber. This is already important, because There are few places suitable for building an earthen cellar, and the cost and labor intensity of a stone cellar with a cellar are reduced by an amount greater than the amount of labor and money spent on the superstructure. Secondly, the same smaller depth of the chamber allows you to build a cellar “on high water” instead of an expensive and complex caisson chamber or half-caisson with drainage. And finally, full ripening of home-made Russian drinks is possible only in the cellar. In general, if you decide to build such a cellar (the diagram on the right in the figure), and then take a sip of kvass from the cellar and compare it with a draft keg, not to mention a bottled one, the question can be considered settled.

Appearance and arrangement of a cellar with a cellar

Note: by the way, the production of some branded and foreign traditional drinks, alcoholic and non-alcoholic, includes an aging stage in conditions similar to those in a cellar. In addition to apple cider and Calvados, they ripen in the attic.

Storage without bund

You can build a storage facility that will not differ in appearance from an ordinary outbuilding. This is a ground cellar without embankment. Its construction is also not difficult.

First you need to draw up a plan for the future structure. It indicates the natural dimensions, as well as the configuration of the structure to scale. According to the created plan, you need to mark the site. The top layer of soil is removed. Here you will need to dig a hole about 60-70 cm deep. The soil is not removed from the site. It is folded to the side.

The prepared site must be thoroughly compacted. Gravel or expanded clay is poured onto the bottom. The second option is preferable. It will serve as additional thermal insulation. When this layer is compacted, sand is poured on top. It is also leveled and compacted. Each of these layers should be 10 cm thick. Next, the pit is lined with waterproofing. It should rise over the sides of the pit.

Next, you can fill the base with cement. The screed should be 3-5 cm thick. It is covered with film and watered periodically with water. This avoids cracking of the solution.

You can use brick and mortar instead of concrete. The layer in this case should be at least 10 cm. You can lay the bricks flat on the soaked clay. Each subsequent row is made with an offset.

About ventilation

Ventilation in the cellar is necessary because... During storage, plant agricultural products emit gases, primarily ethylene and aldehyde vapors. Products affect each other with their evaporation, which reduces shelf life, so air must be removed from the cellar, accepting the loss of cold.

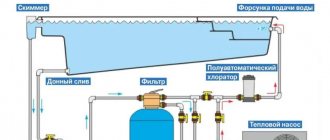

Exhaust ventilation in the cellar

For vegetable storage, exhaust ventilation will be optimal, on the left in Fig. The hood is brought 0.5-0.8 m to the bin that emits the most gases: potato or apple, on the right in Fig. It is highly desirable, as already said, to have its own hood with an umbrella over each bin; in a small cellar they can be combined into one outlet pipe. The flow of outside air is ensured by openings with dampers in the doors.

Smart owners in vegetable stores make a hood with a whistle: instead of simple holes, they equip the doors with whistles, like a kettle boiling alarm, only bigger. The fact is that the release of gases from products decreases closer to the exhaustion of shelf life; this process spreads in the bin or pile from top to bottom. A vacuum occurs in the cellar chamber and the flow of outside air increases. That is, if the fistula “sings” in calm weather, it’s time to sort out what’s stored.

Cellar with supply and exhaust ventilation

In universal cellars, with pickles and preparations in open containers, smoked meats and animal products, supply and exhaust ventilation is necessary, see fig. on right. Its design is similar to basement ventilation, see below, but for a cellar, in order not to pull the pipes high up, the hood should be insensitive to the wind and work only on draft. To do this, its diffuser cap (diffuser) is equipped with a ring seal, as in industrial ventilation.

Completion of the wall structure

After creating the foundation of the above-ground cellar, you need to lay out the walls of brick or foam blocks. The masonry is done in one brick. Internal and external walls are carefully plastered. For this, a cement mixture is used. The outside walls are covered with bitumen. You can also make a layer of thermal insulation (if winters are cold) from polystyrene foam.

Next, the roof is created. In this case, it should be single-pitched. The roof can be made from slabs. It is covered with a layer of waterproofing. You can make the roof from the same material as the cottage. In this case, you will need to build a rafter system. It is covered with hydro- and thermal insulation. Next, a wooden sheathing is made. It is covered with slate, metal tiles, corrugated sheets or other suitable material.

It is also advisable to cover the walls with dry, fertile soil. Climbing plants are planted here. You can also plant low-growing perennial bushes and flowers here. A trench is dug around the building to drain water.

Natural ventilation is provided inside the cellar. The door also needs to be covered with insulation. If desired, you can make an entrance to the storage from the side of the house. This will make using the cellar much more comfortable. If the door is located on the street side, it must be insulated. A small dressing room is set up inside.

Glacier

In a cellar with a glacier, 9-10 months are possible. maintain a temperature of 3-7 degrees per year, and wait out the peak of the summer heat at 12-15 degrees. This ensures the storage of many types of products until the new harvest. At the same time, building a glacier in a cellar is not so difficult, see fig. The glacier bowl is made of waterproof concrete; You can use a bathtub with additional foam or foam insulation. The bath is convenient because the drain siphon does not allow unmelted sludge into the drainage, but in general its volume is small: for a good glacier you need more than 1 cubic meter. m. In a concrete bowl, slush is held by an inclined partition in a condensate collector.

Construction of a cellar with a glacier

Both ventilation pipes of a cellar with a glacier should not “catch” the wind pressure, for which they are equipped with wind-independent diffusers. During normal operation of the glacier, the mass of melting ice slowly sucks in outside air and cools it, cold air also slowly flows to the floor, gradually heats up and goes into the hood. If the spring wind blows properly into the inflow or through the hood, all the ice can melt in a day or two. In addition, the optimal air humidity for storing plant products is 80-90%; the same value is acceptable for livestock products. But without an exhaust hood and in the presence of a source of water vapor in the form of melting ice, the humidity can reach the condensation threshold, which is unacceptable for both.

When constructing a cellar with a glacier, special attention should be paid to drainage. If the cellar is on a dry hill, see below, there are no problems even with a non-buried one: the drainage is discharged to the ground below the slope. But dumping it into freezing soil, even the most porous one, is unacceptable: hidden ice may form, and in the summer this can lead to local suffusion of the soil, i.e. its sudden drawdown in the form of a hole. This hole can be anywhere, incl. and under a residential building.

Types of materials used for internal waterproofing

If you made a cellar in your country house with your own hands from waterproof concrete, then you are unlikely to need additional cladding with insulating material. But for a brick structure you can use the following waterproofing options:

- mastic or bitumen - used in cases where the groundwater level is below floor level. The solution is heated and applied in a thin layer to the walls, resulting in the formation of a reliable waterproof film;

Membrane type waterproofing material.

- penetrating waterproofing is the most expensive, but also the most effective option. It is good because it increases not only the level of resistance of walls to moisture, but also their frost resistance. Also, penetrating waterproofing reliably seals all cracks and micropores, is characterized by a long service life and is quickly installed;

- Cement-based polymer mortar is one of the most reliable and easy-to-apply waterproofing materials. It fits tightly to the walls and reliably protects them from mechanical damage;

- membrane-type moisture insulation - consists of various polymers, among which liquid rubber based on bitumen is very popular.

Note! It is very important to have effective ventilation for reliable waterproofing of a cellar in a country house with your own hands. How to build a ventilation system so that excess moisture does not condense in the storage? The installation of a supply and exhaust system is best suited for this.

Diagram of the thermal and waterproofing of the cellar.

We are building a cellar

The construction of the cellar in stages is as follows:

- Choosing a location;

- Soil research;

- Determining the depth of groundwater;

- Choosing the type of cellar and material for construction;

- Digging a pit;

- Foundation structure;

- Construction of the camera;

- Backfilling from above or erection of a superstructure;

- Equipment: hatch (manhole), doors, shelves, bins, etc.

Place

The best place for a cellar is on a dry slope or slope. A cellar on a hill would also be good. In both cases, if the continental soil is sandy loam, the construction of a glacier will not cause difficulties, see below. On other soils you will have to take care of drainage. A cellar without a glacier can be built on level ground, but an earthen cellar is undesirable.

Is it possible to make room?

Allocating land for a cellar is sometimes difficult, and building a bunker is extremely difficult and expensive. Hence a completely natural question: is it possible to place a cellar under existing buildings? If there is already a basement there, then the question of building a cellar disappears altogether, except perhaps as a storehouse in a commercial economy.

The first thing that comes to mind is home, it’s convenient, you don’t have to go far. However, firstly, the construction of a cellar under an existing house is more complex than repairing the foundation and is possible only when the house has completely settled, i.e. no earlier than 3-5 years after completion of construction. Suddenly the foundation cracked, there’s no getting around it, but about the cellar you need to think and think, there’s plenty of time.

Secondly, a cellar cannot be built under a house on any foundation. For example, columnar, pile and slab constructions definitely exclude the construction of a cellar. In fact, the only type of foundation for a house on which a conscientious builder will undertake to develop a cellar project is a recessed strip foundation, i.e. normal, below the NGP, depth. And then, if the size and layout of the house allows you to maintain a distance from the pit for the cellar to the inner sides of the tape of at least 1 m. But all the same, so much land will have to be allocated for the entrance to the cellar, and its construction will be so complicated, see Fig., that It would be easier to build a separate cellar next to the house. And this is not counting the manual, and no other way, digging of the foundation pit under the building and the mandatory resettlement of residents during construction. It’s another matter if there is no land for a cellar on the site, and the house is just being built. Then you need to include a basement in the project; it will be simpler and cheaper in every way.

Entrance device to the cellar under the house

Thirdly, the temperature in the cellar under the house cannot be kept below 13-15 degrees, because... winter heat loss at home will fall precisely on it. If the temperature in it is forcibly reduced in some way, then there is a high probability that the floor of the house will become damp. Amateurs sometimes build cellars under houses, but this is a lottery: one is lucky, but how many don’t know what to do now? Naturally, they don’t brag about it on forums and don’t post videos.

In fact, the only case when building a cellar under a house is justified is if the wine cellar is in places with consistently sub-zero winters. Then the temperature in it will be just right for the maturation of wine materials. If the temperature in the cellar drops below about 10 degrees, the wine material may “catch a cold”, its taste and bouquet will deteriorate. By the way, it is not necessary to plant vineyards in frosty regions; young wine can be purchased; perhaps distill it and age it at home. The limestones near Moscow perfectly age cognacs, the wine spirit for which is purchased on the Don. But in this case, experienced professionals must design and build the cellar, because... There are no completely identical houses, just as there are no matching fingerprints. To take into account all the available circumstances and develop a project based on them, you need to be a very experienced and competent builder. Yes, amateurs also sometimes build wine cellars themselves, but this is already a double lottery. Even though the design turned out to be reliable, we still need to try what kind of wine is ripening in that cellar.

Scheme of ventilation of the cellar under the house

The garage is another matter. Even if it is heated, no one will keep it above +12, it’s ruinous. In the cellar then it will be +(7-8), which is just good. And in the summer, the garage will serve as a heat damper like a cellar. It’s better, of course, not to try kvass “from the garage,” but warming up the cellar in the summer can most likely be avoided. It’s a shame to break an existing screed, but it’s not a disaster.

In a standard garage of 7x4 m, a cellar of 2x (1.5-1.7) m is placed along the blank rear wall. Taking into account the fact that the edge of its box should be no closer than the same 1 m to the foundation of the garage, the inspection hole will have to be shortened. But, since you most often have to climb into it because of the transmission, this is not so scary: suddenly you need to look from below under the hood, the car can be rolled away. If the body is an ordinary sedan, then there are no problems at all, because There is no need for space in the back to lift the 5th door. In general, a cellar in a garage is somewhat more labor-intensive, but optimal if there is a lack of free land on the site. Let's see how to build it further.

Note: the cellar under the garage must be equipped with separate ventilation from the garage, the same as the basement, see fig. on right.

Priming

To determine the nature of the soil in an attractive location, humus is removed to the underlying (continental) rock in an area of 0.5x0.5 m. The ideal soil for a cellar is dry, slightly heaving; for a cellar with a glacier - permeable for the sake of ease of drainage, but not excessively, so that the runoff does not migrate where it is not needed, combining high heat capacity with low thermal conductivity. Load-bearing capacity is not particularly important, the load is small, but ease of development is important, because You'll have to do a lot of digging by hand.

Types of soils

Rocky soil (item 1 in the figure) is not heaving and has a heat capacity, but is thermally conductive and is very difficult to dig. Clastic (semi-rocky) soil is close to ideal, pos. 2, because it swells little even when heavily moistened, but it is impossible to release runoff from the glacier directly onto it; water in such soils migrates far and unpredictably. Digging in clastic soils is also not easy.

The best soil for a cellar is sandy loam, pos. 3. It satisfies all the conditions of “ideality”, except for heat capacity, but it can be increased by filling the chamber from above; The slopes of the earthen cellar chamber in sandy loam must be strengthened with wooden panels. Loam, pos. 4, worse: conducts heat well and, being waterlogged, swells greatly. It is better not to build a cellar in loam on level ground.

Completely unsuitable for cellars as load-bearing soils, sand, pos. 5, and clay, pos. 6. But they will be great for backfill and pillow. Natural self-dug sand is good because it is not divided into fractions, and this is what is needed to build a cellar. If there is dry peat in the vicinity, pos. 7, it can (and should) be placed on the very first layer of top backfill, counting from the chamber; the clay with sand and turf is then “pushed apart” to accommodate a layer of peat. It is an excellent heat insulator and desiccant; food stored in a cellar with peat lasts much longer.

Silty soils, pos. 8. They can be recognized as dry by their dull gray, somewhat dusty color and putrid, musty, muddy odor, which intensifies when the sample is wetted.

Groundwater and material

An earthen cellar can be built at least 1.5 m above groundwater, a brick cellar - at least 1.2 m, and a monolithic concrete cellar at least 0.7 m. The depth of the aquifer surface is determined during the period of highest groundwater; in the central zone of the Russian Federation this is the end of April - the first half of May.

A test for water height is made on the same site where the soil type was determined. Conducting test drilling is difficult and difficult, but in this case an old “detector” made of wool with an egg will help out. They don’t need to look for drinking water, because... It “catches” first of all the dirty high water, but for the cellar you just need to “catch” the highest water.

The “detector” is prepared in the evening. To test, place a piece of clean new, unworn felt the size of a plate or a piece of wool of the same size 3-5 cm thick on a site without humus, and a fresh chicken egg on it. The best thing is freshly picked and warm. In this case, the egg checks the moisture absorption of the soil, because emits water vapor. The “device” is covered with a thick cap (cauldron, pan) and its edges are pressed to the ground; Covering them with soil won't hurt.

The next morning, preferably immediately after sunrise, they look at what happened there. The results are interpreted as follows:

- The egg and wool are dry - you can build any cellar.

- The egg feels damp to the touch, the wool is dry - you can build a brick or concrete cellar.

- The egg is dry on top, the wool feels damp to the touch - the cellar is only concrete.

- The egg is covered in dew, the wool looks damp, and when you squeeze it in your fist, even a little water is squeezed out - you can’t build a cellar.

Note: if the cellar has a door and not a hole, then the entrance is oriented to the north. It is also highly advisable to orient the door of the upper structure to the north.

About cellars on high water

Scheme of anti-pressure waterproofing

It happens that a cellar is needed, but the water in the area is high underground. In this case, it is also possible to build a cellar by installing pressure-resistant waterproofing. But this work is by no means for an amateur: the insulation scheme is developed by specialists based on on-site survey data, and there are no universal standard solutions as such. Secondly, this work is difficult and expensive. For example, in Fig. on the right is one of the pressure insulation diagrams. We emphasize that there is only one, tied to specific local conditions. Successful amateur buildings should also be selected for the basis in consultation with specialists: there are no identical local conditions; What's dry there will get wet here.

Pit and base

It is better to rough-dig the cellar pit, of course, with an excavator, but the hole is brought into shape manually. They dig with their hands using a “plow”, scraping off the loosened soil with a shovel to a dense “matter”, i.e. continental soil. The shape of the pit is an overturned truncated 4-sided pyramid; so it is necessary that the bottom and side backfill counteract the forces of heaving. A cube box in a pit, especially a brick one, will have to be reinforced by reinforcing the seams and corners, which is expensive, labor-intensive and far from 100% reliable. The reserve for backfilling for stone and concrete cellars is approximately 0.7 m in depth, counting from the lower surface of the chamber floor; width - 0.5 m at the bottom and 0.7-1 m at the top. Enlarging it won't hurt in any way. For a wooden cellar, a hole is dug to size and stakes are immediately driven close to the walls, to which the lining will be attached. The depth of driving into the mat is from 30-40 cm.

Note: the pointed ends of the stakes are burned over a fire until charred to a depth of 0.5-1 cm, turning continuously. If it catches fire, extinguish it in the sand; Do not fill with water! Then impregnated with oil protective compounds for wood; you can use mining. A water-polymer emulsion, a lifesaver in many cases of working with porous materials, will not last long in the ground.

Next, the bottom of the pit is covered with sand to a depth of 20-25 cm and, after sprinkling lightly, tamps it down. You can use a tamper or a hand roller for garden paths. A 1:1 mixture of sand, not sorted into fractions, with fine crushed stone screenings is poured onto the sand cushion, i.e. the backfill should contain all fractions from the smallest grains of sand to grains the size of a sunflower seed or pea.

The second backfill is leveled horizontally with a rake or scraper on the handle and compacted without wetting. Finally, very hot, almost boiling bitumen is poured over it evenly from above until a “mirror” is formed. But you can’t overfill it; the layer of bitumen above the backfill should be 3-4 mm. This is the base of the cellar; further depends on the material of construction.

Box

Earth and tree

If the cellar is earthen, then an adobe floor is formed over the hardened bitumen. When covering a chamber with wood, the panels are first installed, and then the floor is filled.

Brick and stone

For a brick cellar you need dense, dark, well-burnt iron brick. Bulging and warping (“propeller”) by 3-4 mm, i.e. no more than a third of the thickness of the masonry joint, not a hindrance; It is important that you draw less water into yourself. Even better, but more expensive, would be concrete foundation blocks or shaped blocks made of waterproof concrete, see fig.

Masonry cellar made of blocks

The laying is carried out along a bitumen surface. The first row is placed with a poke, i.e. the bricks are laid crosswise, the corners are laid out along the short side, see fig. on right. The next rows are placed in spoons with a simple chain ligation of the seams. In a properly constructed pit, half a brick of masonry will be enough. If you want to lay the walls in brick for safety, then the scheme is usual: a butt row after 4-5 spoon rows. If a staircase opening is needed, its framing is placed with fence-style pillars, in a brick with an empty core, the same fig. It is advisable, if you have something, to reinforce the seams, as when building a cellar in a garage, see below.

Brickwork for the cellar

After the finished masonry has dried, the outside of the box (preferably from the inside too) is soaked generously, twice, with bitumen mastic. Modern ultra-deep penetration stone primers are even better, but expensive. Primers that simply penetrate deeply are not suitable. Further work is carried out after the primer has completely dried; for bitumen it takes a week or two, depending on the weather. During this time, protect the box from rain by stretching a tent over the pit with a film with gaps above the ground.

Concrete

For a concrete box, it is better, of course, to order water- and frost-resistant concrete of medium plasticity, but you can get by with homemade one. The composition is also common: cement M400, sand of medium (1 mm) fraction and fine crushed stone 1:2:4. Water – 170-190 liters per cubic meter of finished solution; more on the floor, less on the walls.

First, the base is filled with 40-50 mm of concrete; It is good to add a plasticizer to the solution for it. When the footing has set, a reinforcement frame is assembled, common to the floor and walls. The reinforcement scheme is standard; floor 150 mm thick, walls 200-250 mm. It is very convenient to use plastic reinforcement; then the frame is pre-assembled at the top and simply placed in a hole on a hardened concrete base. This will make the entire monolith more reliable.

Having assembled/installed the frame, the formwork is installed. First the floor is poured; as soon as it grabs, the walls. You can’t delay, just like with the concrete base: the entire monolith must be poured long before the concrete gains strength, otherwise it won’t be a monolith. The walls are poured in layers, in the same order as when laying a strip foundation. Since vibration compaction is not applicable in this case, the poured walls are bayoneted, the same as when building a foundation.

It is better to pour the monolith in spring or autumn: in hot weather, the concrete will “mature” too quickly and the monolith will turn out to be fragile. After setting, the monolith is moistened as required for concrete work. After gaining strength (20 days at +15 and 7 days at +25), they are treated with bitumen mastic, like a brick, or, better, with an ultra-deep primer, but on concrete. The final stage is the formation of the floor screed.

Wood work

The construction of any chamber is completed by the flooring of its upper floor. Most often, the cellar is covered with a slab in 2 layers crosswise; this is strong enough for a cellar and cheap. If provided for by the selected design, make a log floor in 1-2 rolls. All wood for the cellar must be treated with oil compounds or treatment; boards for the internal lining of a wooden cellar too.

Top fill

The hill above the cellar is poured according to the scheme of the selected sample. Clay in it is waterproofing and a cold accumulator; sand is a heat insulator. You don’t have to stand on ceremony with them: the thicker the better. The thickness ratio of the layers is approximately 1:2 or 1:3 (clay:sand). The role of peat has already been mentioned; 20-40 cm is enough. Turf directs surface runoff to the sides.

Arrangement

The cellar vestibule will be the simplest and cheapest, prefabricated panel with foam insulation. Suddenly, this part of the building is completely repairable. It is better to make a cellar made of logs or timber; other upper structures - according to the project or selected sample.

Ready cellar hatch

Special mention must be made, firstly, about stairs and hatches. The staircase to the cellar, if it is not an extension, must be made either in stringers, or between the walls of the vestibule, on the left in Fig. below. Stairs with hanging steps, on the right there, can be beautiful, but in the cellar they are very dangerous.

Cellar hatches with lifting mechanisms (see figure on the right) are available for sale. They open/close with a light touch. However, if you’re not too lazy to push yourself a little, you can make a cellar hatch yourself from leftovers and scraps. Its diagram is in Fig. left. Insulated cellar doors can be made in the same way.

Construction of a homemade insulated cellar hatch

Secondly, electrical wiring. The cellar, according to PTB, is a particularly dangerous room in terms of the degree of electric shock. The power supply in these is 12 V and not a volt more. In the basements of apartment buildings, the wiring is 36 V, but there are no sockets, there is a light switch outside a particularly dangerous room, and residents do not have access to electrical work in underground structures, but they have a utility electrician at their disposal.

The cellar must be powered from a 220/12 V isolation transformer wound with copper on iron. Electronic inverters do not provide proper separation of 220 and 12 V circuits. Between the windings of the transformer there must be a static screen (an open coil of copper or aluminum foil), electrically tightly, i.e. soldered or welded, connected to the magnetic core of the transformer. The magnetic core itself is also tightly connected to the house grounding bus or to a homemade grounding circuit; A couple of pins will be enough in this case. But grounding the transformer through a three-pole Euro socket is unacceptable!

The nuances of arranging a cellar with your own hands at a high groundwater level

When choosing a location for storage, it is very important to take into account factors such as total soil moisture and groundwater level. The lower it is, the easier it will be to build the structure, and the less often repairs will be needed. If we are talking about a free-standing structure, then you should choose the highest place on your site. It is best to determine the groundwater level when it is at its maximum, that is, in spring or autumn. If there is a well or borehole on the site, then you can determine the maximum elevation using them, otherwise you will have to drill a well separately. It will be somewhat more difficult to build a cellar if groundwater is close. How to do this as efficiently as possible? First of all, it is necessary to pay great attention to the waterproofing of the structure. Also, with increased soil moisture, for better waterproofing of the cellar from groundwater, it is worth using building materials characterized by increased resistance to water. In this case, you should not use wood or plywood, but rather give preference to concrete and brick.

Scheme of a separate cellar: 1 - foundation; 2 - steps; 3 - protective fence; 4 - walls; 5 - ceiling vault; 6 - ventilation; 7 - waterproofing; 8 - bulk soil.

Helpful advice! You can also check the groundwater level using folk signs. To do this, you need to leave a piece of wool and a chicken egg at the construction site, and cover them with a clay pot on top. If in the morning there is dew on both the wool and the egg, then groundwater is close, but if there is only dew on the wool, it is far away.

Cellar in the garage and under the house

It's time to remember the promised cellar in the garage. In a similar way, a cellar under a house with a hole from the room is built, but then you will have to break the floor, break the ceiling, and carry out cubes of earth in buckets when digging a pit. The figure shows step by step how to build a cellar under a garage:

Building a cellar in the garage

- Build a brick box as described above, because concrete work in such conditions is unrealistic;

- Masonry joints are reinforced with perforated steel strips 2-4 mm thick. It is convenient to use press and stamping waste. This is necessary because it is extremely difficult to construct a normal foundation pit with slopes and anti-heaving backfill under an existing building;

- Steel pins are embedded in the seams of the top row of masonry, and a strip of the same strip is welded to them. There is no point in placing stronger mortgages, because... there will be no wind or other operational loads tending to raise the ceiling. A center beam made of a tee or 2 welded corners from 60x60 to 100x100 mm and a hatch opening from the same or smaller, up to 40x40 mm, corners are welded to the tape;

- The frame of the concrete floor is assembled by welding. The frame stiffeners are assembled from the same strips connected by 12-16 mm reinforcing bars. At the same stage, ventilation and metal conduits for wiring are installed;

- From below, formwork is mounted from 40 mm boards on supports made of timber or logs from 150 mm. The installation pitch of supports is up to 600 mm. The formwork panel is covered with waterproofing in advance;

- The formwork should be 30-50 mm away from the stiffening ribs, as required, but the pipes and corrugations should sit tightly in it, for which purpose the gaps are coated with cement-sand mortar;

- Fill the ceiling 30-40 mm above the stiffeners. As they gain strength, 40-50 mm of foam plastic is laid, retreating from the edge of the slab by 50-60 mm. It is impossible to push the foam tightly; it will soon crumble due to temperature deformations. Sometimes mice are blamed for this, but what should they do in the garage? Insulation stabilizes the temperature in the cellar. Immediately assemble the reinforcing mesh of the floor screed using all the same strips laid flat; the strips are fastened with soft wire, a hatch is installed and the screed is poured;

- The arrangement of the mesh under the screed is shown in more detail.

Note: the depth of the pit for a garage cellar is calculated so that the screed on the ceiling is flush with the floor screed. Absolute accuracy, of course, cannot be achieved, so the floor screed is poured locally with a thickness of 30-120 mm. It is advisable to stay within 50-70 mm.

Construction of the walls of the structure

Walls above ground level (in the absence of a hill or artificial mound):

- They are constructed from 2 layers of boards stuffed onto a frame with layers of insulation (glass wool, sawdust, crushed stone, etc.) and roofing felt (moisture-proof layer). On top of the boards, on nails or large lathing, it is recommended to let perennial climbing plants grow (hops, frost-resistant grapes, vines, etc.).

- When building a ground cellar with a gable roof, everything said in this section remains true, since if the walls are shorter than the tallest member of the family, then it will be convenient for him to use the cellar only in the middle of the basement.

Video on how to easily make an above-ground cellar with your own hands:

Just in case

No cellar is guaranteed against water. Subsurface runoff and perched water are insidious and capricious; they wander underground in the most bizarre way. What kind of repairs the cellar will need if it gets damp is another question. First you need to remove the water; Maybe after this it will be possible without repairs. Specialists charge a lot for draining a flooded cellar, so it’s better for a home handyman to first try to drain the water himself; it won’t get any worse. One of the available ways to drain a flooded cellar/basement is to discharge water into the underlying aquifer. How to make it, see video: