For many, a vacation outside the city means a hot sauna, a delicious barbecue cooked over an open fire, or a quiet evening near a cozy fireplace. For all these pleasures you need well-dried firewood. If you store them haphazardly, the wood will become damp and unsuitable for kindling. The best solution is to build a firewood shed for your dacha, especially since a simple structure can be built in just a few hours from the most affordable materials.

Requirements for firewood storage

Wood is a material that is capricious in terms of storage conditions. Excess moisture leads to dampness and rapid deterioration of firewood. Heating a bathhouse or lighting a stove like this is not the most pleasant experience.

To protect the woodshed from moisture, it is arranged:

- in enclosed spaces with good ventilation - a barn, dressing room, garage or fireplace room in the house;

- outdoors - under a canopy, on a terrace, in a gazebo, an extension or a summer kitchen.

Firewood should not come into contact with wet ground or tall grass, so outdoors it is placed on waterproof bases. The wall-mounted design requires protection from precipitation flowing from the roof of the house directly onto the woodpile.

Fences are made with a large number of slots for air circulation. Do not allow wood to come into prolonged contact with heated surfaces, for example, a sauna firebox or a stove. It is prohibited to store fuel in boiler rooms or other places where sparks from open fire may occur. In addition to optimal storage conditions, it is necessary that the structure be durable, stable and ensure compact stacking of firewood.

By the way, recently subscribers described how to make a rabbitry with your own hands and detailed instructions for creating a chicken coop for 10-20 chickens, it will be very interesting to read.

Firewood holders for fireplaces and stoves

If you have a stove or fireplace in your house or enclosed gazebo, then you need another firewood rack. It can be stationary or portable.

A stationary firewood rack is made in the form of special niches or shelves next to the stove or fireplace, which fit harmoniously into the overall interior.

If during the renovation you did not think about or plan for such a niche, then a portable stand for firewood will be the way out of this situation. It can also be used in small enclosed gazebos.

Forged firewood stands are very original and beautifully made, which can be used not only for storing firewood, but also as a chair-bench.

Baskets woven from wicker are also used as firewood. But they are not durable, so they have not gained much popularity.

Housewives handicrafts sew decorative covers for woodpiles from burlap and weave from thick rope. They look very modern and original.

Using imagination and creativity, craftswomen decorate homemade woodpiles with appliques and embroidery. And you can knit or sew an original design piece.

PHOTO

Similar

Types of woodpiles

The woodcutter can be portable or stationary, in the form of a stand, rack, bowl or shelf. Dimensions are determined individually, taking into account the dimensions of the site chosen for storage, as well as ease of use and safety.

The optimal depth of the woodshed depends on the length of the logs that will be used for kindling:

- for a bathhouse or stove it is at least 50 cm;

- for an indoor fireplace, 25 cm is enough.

The height of the storage should not exceed the height of a person, otherwise it will be inconvenient and possibly even dangerous to use. If it loses stability, the woodpile can collapse and injure a person.

About terminology

Drovyanik is often called drovyanik in certain regions of the Russian Federation and in other Slavic languages. The term “woodshed” is also often used. We will do both, and the third, but first let’s decide what is what:

- A woodshed is usually a woodshed with a door, standing on a foundation separate from the house.

- The woodshed is a simplified woodshed in the form of a canopy attached to the house, resting on a blind area around the house. (Outdated meaning - small firewood dealer peddling from house to house).

- A firewood rack is a stand for a consumable load of firewood for heating a fireplace or a basket for carrying firewood. Often both are combined in one product, see at the end.

Materials for woodshed

For production use:

- wood - boards, round timber, beams, slats;

- wood materials - plywood, OSB, chipboard;

- metal;

- brick;

- blocks;

- roofing materials;

- cellular polycarbonate.

Any available materials, construction pallets, obsolete utensils or furniture can be used. There are no restrictions on their use, but for outdoor conditions, moisture resistance is an important criterion.

Tree

This is the most affordable material for making a woodcutter with your own hands. It is easy to process, and with the help of mechanical fasteners you can assemble any spatial structures.

Wood combines perfectly with any other materials for country house construction. To be used outdoors, lumber must be treated to prevent rotting. They can be coated with waterproof impregnations, paints, and stains. For decoration, forged elements, decorative grilles, and clapboard cladding are used.

Metal

A durable, strong woodshed can be built from metal profiles, pipes, corrugated sheets, sheet metal, and fittings. The frame is assembled using welding, bolts or rivets. The outside is sheathed with boards, metal mesh or any other materials as desired. Metal parts are treated with a primer and metal paint.

In the wall-mounted version, the back part of the woodshed is already there. Racks or walls are installed on the sides, and the top is covered with roofing material sloping away from the wall.

Wall-mounted forged firewood

Brick

The brick woodshed is a solid, solid structure. Most often it is provided as part of a complex of an oven, barbecue and barbecue in summer kitchens or gazebos.

Brick is durable, not afraid of rotting, corrosion, and fire. But it is quite heavy, so it requires a solid foundation. It can be poured from concrete, laid out from blocks or bricks.

Polycarbonate

The woodshed made of cellular polycarbonate looks elegant and harmonizes with the surrounding country houses. The material protects well from precipitation, preventing the wood from getting wet. It can be transparent or colored and can be combined with any building materials.

For the installation of firewood, sheets with a thickness of 4-6 mm are used. They are attached to a frame made of wood or metal using roofing screws. The edges must be covered with protective profiles to prevent moisture from entering the cells and rapid flowering.

Non-standard solutions

The woodshed can be built from unusual materials:

- wooden barrels and other used containers;

- unsanded logs;

- sewer concrete rings.

The barrels are placed on their side on a non-rotting stand and firmly secured. After treatment with antiseptics, a simple but convenient woodshed is ready.

An interesting option is a woodpile for firewood made of a concrete ring, imitating the cutting of a huge round log. Manufacturing comes down to installing the structure in a recess and further decorative finishing. To imitate bark, textured plaster with a cement binder is used. The relief is created using a spatula, a roller attachment or fingers. After the solution has set, paint the surface with facade paint. To protect the ends of the rings from slanting rain and snow, you can install shields made of boards or moisture-resistant plywood.

Scandinavian woodcutter

The Norwegian-style firewood box looks very unusual and beautiful. This is a small house with plank walls and a squat, wide roof. The originality of the building lies in the fact that it is a frameless structure.

The boards are laid like crowns, that is, with a remainder. Cuts are made in the end parts of the boards. Each element rests on 2 neighboring ones and is rigidly clamped with a locking connection. There are gaps between the boards for ventilation, which creates a favorable conditions for drying even a large amount of firewood. The roof is made of lightweight material, such as flexible tiles.

In Scandinavian countries, not only utility blocks are built in a similar way. Not very nice objects are hidden in them, for example, transformer booths.

What are there

A sheet of metal will protect the walls from woodworms (wooden ones, of course)

. If you do not pay attention to the size, there are two types of sheds for firewood - attached to the wall of a building or standing separately. It is clear that it is easier and faster to install, but this is not always possible. Or rather, not with all buildings: it is dangerous to build on wooden walls. And not only from a fire safety point of view. With the firewood comes a whole army of wood-boring beetles, which will happily take on your home. Therefore, it is better not to attach woodsheds to wooden buildings, even with wood treated with bioprotection, but if you really want to, then nail an iron sheet to the wall. As in the photo. It should be larger than the size of the woodcutter. Then all the bugs (most of them, for sure) will remain in the firewood.

Free-standing firewood sheds can be completely open - several pillars, a couple of lintels and a roof. The main thing is that the roof is large enough: it is advisable to make larger overhangs. And the rest will be completed by air and sun. They say that they dry no worse than in more closed structures. In regions with heavy snowfall, to prevent snow from getting inside for the winter, sheets of plywood are attached (attached) below. They are removed in the spring.

How are walls made?

More often, woodsheds are built with lattice or slotted walls. It is better if the boards are stuffed at some angle - like blinds. Then, even with oblique winds, little precipitation gets inside. But even if the boards are filled at some intervals, everything dries well.

Boards/slats are placed on the frame mostly horizontally, sometimes vertically; they also make lattices from thin planks or place them diagonally. In any case, there should be a lot of cracks for ventilation.

Vertically stuffed planks are rare. This is a woodshed with a pitched roof

Does the drying speed depend on the method of installing the planks? No comparisons have been made, so it’s difficult to say for sure. But one owner claims that if you lay the boards diagonally (he has 10 cm with a 2 cm gap), with each wall in a different direction, it dries faster and faster: in a month.

About the size of the slots: they are made from 2 cm to 10 cm. But it also depends on the width of the board. If you leave the gaps very wide, snow will sweep in a lot. If there is little snow or you are not concerned about the amount of snow, you can fill the boards less often. It's also more economical.

Beautiful woodshed for the dacha

Not all woodsheds have doors (those with doors are also called “woodsheds”), as in the version in the photo. Often there is not even a front wall: this allows for more active ventilation. The front wall and doors are needed if stealing occurs in your area, but in general you can do without them.

Log location

Now a little about the structure of the woodshed. If it is small and everything fits in one row, then there are no special problems - everything is accessible. But if large volumes are loaded, it is better to divide the area into sectors into which batches of firewood will be loaded. Thus, previously imported and already dried out ones will not be covered by fresh ones.

It is better to divide the area into sections, so that you can go inside

If the woodshed is square, arrange the sections so that you can reach inside to remove the driest logs. To do this, a passage is left in the middle. In terms of depth, it should not be up to the wall, but it is advisable that only one, or maximum two, rows of logs separate you from the wall (and in general it depends on the volume) - this way they will all be accessible. It’s easier with rectangular ones: they are simply separated by non-sectors by a partition. For example, as in the photo.

This is a large shed for firewood - each section fits one car - about 4 cubic meters. The back wall is not solid; if you look closely, there are holes there.

And a little about height. You don’t need a large woodcutter for a (seasonal) dacha. All you need is one or two cubes for heating in the fall/spring, and even then only for the weekend. But if you have to heat a house, and even a bathhouse, you will have to build something solid. Then, regardless of the layout - long or square, the height is about 2 meters. With average height, you can load it almost to the ceiling. but there should be a ventilation gap at the top.

Read about how to make beautiful and inexpensive paths in your garden or on your property here. You can read about the construction of a homemade pond in this article, and about how to turn it into a fountain, here.

Where to put a woodshed in the country

The most convenient place is near a recreation area, a bathhouse or a summer kitchen, so that you don’t have to go far to get firewood. The woodshed should not interfere with movement around the site, reduce the illumination of the plantings, or create discomfort for viewing the surrounding beauty.

The site should not be located next to a body of water - the air contains a lot of water vapor. Do not store wood in a basement or underground where there is poor ventilation and a high risk of fire.

It is also undesirable to attach the storage unit close to the wall of a wooden house. Such proximity can lead to rapid infestation of structures with woodworms, since a large number of pests nest in firewood. A gap of at least 20 cm or a sheet of metal placed between the wall and the woodshed will solve the problem.

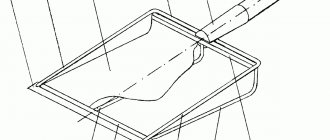

But if the storage cannot be organized closer to the gazebo or summer kitchen, we suggest making a special lightweight stretcher. For production, durable fabric, wood, plywood, wire, and rope are used. The bottom and walls of the future carrier are cut out in such a way that it is possible to stack a certain amount of firewood. Handles are attached for convenience. You will be able to bring a large armful of logs in your hands in one go.

Selecting a location

Place the woodshed away from barbecues and other sources of ignition. You should not build a woodshed near a garden or vegetable garden, as this is usually a rather large structure and shades the area. This should be an elevation (in the lowlands the firewood will become damp) where the wind blows. In this case, it is worth considering the possibility of travel to the building. For fire safety, a distance of at least 4 meters is maintained from the house to the woodshed.

How to stack firewood for long-term storage

At a time when firewood was practically the only fuel, even children mastered the skill of stacking woodpiles. Now this activity is almost forgotten, but the principles are passed on from generation to generation.

If you stack the logs incorrectly, mold and rot will appear on them very quickly. It is important that the stack remains ventilated while maintaining stability.

Basic installation rules:

- At the bottom, a belt of tree cuts, log trims is arranged, or lattice panels are used.

- The first rows of logs are placed at an angle, filling the space with the most low-quality firewood - knotty, difficult to chop, etc.

- Then good logs are used, row by row they fill the depressions between the underlying logs.

- Fill the entire woodpile evenly. For stability, supports are installed on the sides of the stack. In a woodshed with vertical walls, the firewood will lie without the risk of falling apart.

There is no need to achieve too much density. The logs are also removed gradually, starting from the top row, in order to maintain the stability of the entire woodpile.

Some people practice stacking firewood by changing the direction of the rows. First, the logs are laid across the stack, then along. This method is most appropriate when the wood is still completely raw, and the logs are large and have approximately the same size.

How to fold an oval or round woodpile

Laying without side reinforcements in the form of a free-standing stack is possible. The firewood is placed evenly in a circle or oval, making sure that there is no distortion. The middle is filled in random order.

For stability, it is recommended to lay thin boards or slabs in the transverse direction every few rows. When finished, cover the woodpile on top with roofing material, film or slate.

Finishing

Wooden gazebo-sheds require good regular care. The paint layer should be renewed every six months. You can impregnate the wood with heated drying oil, which is applied in two layers. Cover the top with oil paint or leave it in its natural form. To prevent the wood from rotting, it is better to install a house made of timber for the household needs of a dacha on a special platform - a flat platform made of concrete, boards, or paving slabs.

Photo: terrace with a relaxation room and a utility room with a gable roof

Pots of flowers on the windows, a wall of green climbing plants, and garden furniture will help you decorate your home built by yourself.

Photo: gazebo combined with a barn under a common roof

A veranda for a summer residence made of timber, combined with an outbuilding, will become a place for relaxation from garden work and simply for pleasant time with the family.

It is clear that building from timber is not as simple as it might seem at first glance. It will take time, material costs and physical strength of the owner. But the site will acquire such a necessary structure for a dacha, such as a change house with a veranda, built under one roof. In addition, any work done with one’s own hands warms the soul and increases self-esteem.

How to strengthen the frame

When stacking firewood at a great height, the entire system may become unstable over time. This can happen arbitrarily due to drying of the wood and changes in its geometry. The woodpile can “play” both in the longitudinal and transverse directions. That is why the frame must be securely fastened.

Lateral loads can be significant. To perceive it, the racks are immersed in the ground at least 50-80 cm. If these are metal pipes, they are hammered with a sledgehammer to the required depth. To protect the metal from corrosion, the bottom of the profile must be coated with mastic and dried.

Wooden supports are buried in holes, having previously been treated to prevent rotting. The easiest way is to use a special antiseptic impregnation. But if there are no special equipment at your dacha, you can use the old fashioned way:

- burn the bottom of the pillar at the stake;

- dip in liquid clay;

- install in the hole, fix and fill with the same clay.

This frame will last 5-8 years.

What are they built from?

Before choosing the material from which you will make the firewood box, decide on the purpose and location. Stationary and portable outdoor firewood burners are made of brick, wood, metal, and stone. Indoors, they can be stationary or portable, used for their intended purpose or be part of the decor of the room.

The raw materials from which it will be made depend on this. For decorative firewood holders, dense fabrics, cord, jute, and glass are used. They are combined and decorated with various elements. Forged firewood racks near the fireplace look gorgeous.

Metal firewood rack for a summer residence

A metal firewood holder is the most durable and reliable. It is made from a lightweight aluminum profile, but for a small number of logs. It is possible to make a portable version.

A stationary woodshed made from a steel round or profile pipe or channel will be more reliable. The frame is covered with welded steel mesh. We cover the metal with primer-enamel or a protective layer of varnish. The fireplace may have a decorative stand for logs made of forged elements.

Wooden firewood for a summer residence

Wooden firewood is the most popular. It is easy to construct from scrap materials.

Any wooden blanks (boards, pallets, timber) are suitable for its construction. Making a beautiful woodshed is not an easy task. You need to show imagination and creativity, make the walls carved with beautiful patterns.

They must be ventilated to ventilate and dry the logs.

Foundation for woodshed

In some cases, when storing firewood, a foundation is made of blocks, beams or piles. This is done to ensure free air circulation and also reduce the likelihood of flooding during rain or melting snow.

Most often, the foundation is replaced with ventilated plank flooring. In order to withstand the weight of the wood located above, sometimes reaching several hundred kilograms, it must be strong enough.

Anchors, holders, corners, staples and brackets are used to attach the frame to the foundation. There are 2 installation methods possible:

- Embedded fasteners are installed during the concreting or masonry process, and then the posts are fixed to them.

- If the foundation is made of blocks or timber, the frame is secured in place using metal anchors or screws.

Beam support, galvanized, 140 x 76 x 100 x 2 mm, opened Metalist 1198462

Galvanized or stainless steel hardware is used. When connecting wood to concrete, a waterproofing gasket is required.

How to make a woodshed with your own hands from wood: step-by-step instructions

We propose to build a simple but convenient shed for storing firewood measuring 0.9x1.8 m.

For installation you will need:

- 4 blocks for the foundation;

- 4 boards for logs 1.75 m long;

- 2 boards of 90 cm for the bottom trim;

- galvanized screws 90 pieces;

- flooring boards 18 pieces;

- 4 racks of 1.2 m each;

- three-inch screws 16 pieces;

- rafter boards with an oblique end, 2 pcs. length 100 and 96 cm;

- boards for the top trim of the frame to support the rafters, 2 pcs. length 173 cm and 2 pcs. 76 cm each with an end cut at 30°C;

- 2 boards for rafters 94 cm with a bevel at both ends at 30°;

- plywood 100×190 cm;

- waterproofing area of 1.85 m²;

- soft tiles 1.85 m²;

- 12 boards 90 cm long for side walls;

- boards 178 cm long;

- 2 boards of 193 cm and 2 boards of 100 cm, cut at both ends at 30°.

Work order:

- Place the blocks in the corners of the woodshed and level them. The distance between the outer edges of the blocks is 90 and 180 cm.

- Mount the frame for the base by laying the boards on edge and fastening them with long screws. Each connection will require 2 screws.

- Secure the floor boards with self-tapping screws to the frame at regular intervals (insert a thick nail or strip).

- Install the frame posts, 2 per corner, fix the top trim boards, connecting the nodes with screws.

- Cut the side rafters and intermediate boards at 15°.

- Install the rafter system. Make the step between the beams the same.

- Secure the plywood to the rafters using self-tapping screws.

- Cover the entire surface with roofing felt.

- Lay and secure the tiles.

- Cover the frame with boards at intervals of 2-3 cm.

- Nail wind boards around the perimeter of the roof.

You can decorate the woodshed to your liking. Wood logs, which were made according to these drawings and a description of the step-by-step installation process

Homemade woodsheds: photo

There are many more similar buildings. The differences are small, the principle is the same: the frame is covered with boards with different gaps. There are several examples that were built by the owners of dachas or private houses themselves.

Woodshed attached to a barn at the dacha

To build it, only two pipes were needed, which were dug into the ground and concreted. Two beams were then attached to them. Similar beams were installed on the wall of the barn. Boards were stuffed between them and the roof was secured (cuts of corrugated sheets). To prevent the firewood from lying on the ground, they placed bricks and a sheet of old plywood on them. To make such a canopy, you can use leftovers from construction or buy pallets and disassemble them. Just the right size.

A simple woodcutter for a summer house

The second canopy was made of the same type. It is further divided into sectors in which firewood of different sizes is stored. The foundation for this structure was also not made; the fertile layer was removed, covered with sand, and compacted. Paving slabs were laid. There are bars on it that serve as supports for the crossbars on which the firewood of the lower compartment lies. It turned out neat.

A small firewood shed for a summer house, divided into sectors

Standing separately

The slope of the roof is organized in an unusual way: the front pillars are made higher, there is nothing unusual about this. But there are grooves cut into them that hold the rafters of the pitched roof. That is, the roof does not rest on the top trim, as usual, but on the side pillars. With a light snow load, this design is quite viable; with heavy snow, the roof is unlikely to survive.

These are two about photos explaining the construction process

And this is what happened. The first serious construction is a woodshed with your own hands, and already it’s so good!

You might be interested in reading How to Make a Wooden Gazebo. It can be built in the same style as the woodshed, so everything looks cohesive.

You can read about what a wooden fence can be like in this article.

Firewood cover

A woodpile stacked outdoors in the open air can be protected from precipitation with a simple device. You will need a piece of durable tarpaulin, such as a used awning or canopy, strong nylon thread, scissors and a sewing machine.

Before starting work, you need to test the machine and adjust the thread tension and seam width. Optimal seam quality is achieved with maximum tension on the upper thread and minimum tension on the lower bobbin thread.

Manufacturing algorithm:

- Fold the tarpaulin in half and sew a zig-zag stitch at equal intervals. Take the width of the pockets so that you can put a log inside (about 30 cm). Make bartacks at the ends of the seams.

- If it is difficult to stitch the outer layered edges, it is better to cut them off and remove the grommets with a flat-head screwdriver.

- A piece of tarpaulin that is too wide can be cut in half. Don't forget to tack the seams.

- Insert as even, identical logs into the pockets as possible, and cover the stack with a tarpaulin.