In recent years, tandoors have become closer in popularity to more traditional barbecues, although they require more complex and costly arrangements. Most often, they are not limited to just a complex for cooking in the open air - a zealous owner will definitely provide for the installation of a canopy for his tandoor. If earlier we wrote about how to make an oriental stove at the dacha with your own hands, today we will supplement it with a canopy from bad weather.

What is tandoor

Read also: How to make fried milk

A tandoor is a roasting oven. The first stoves appeared in the countries of Central Asia, where they spread everywhere. A number of countries are famous for tandoor dishes:

- Uzbekistan;

- Armenia;

- Kazakhstan;

- Kyrgyzstan;

- Turkmenistan;

- Azerbaijan.

The popularity of the device is due to:

- easy to manufacture;

- economical consumption of firewood;

- low material costs;

- possibility of preparing several dishes at the same time.

The principle of operation of a tandoor is to cook dishes not on hot coals, as in a barbecue, but from the heated walls of the stove.

Read also: What to eat chicken cutlets with

The very first products were earthen. A hole up to 35 cm deep and 50 cm in diameter was dug in the loess soil. A hole was made on the side for air to escape. Then they decorated the pit like a jug - this way the heat was retained longer and less firewood was consumed.

Gradually in Central Asia they learned to build stoves from kaolin and fireclay clay. Clay was mixed with sand and chopped sheep wool - the solution came out thick and set better. The finished clay tandoor was exposed to the sun for two weeks to dry.

Some general information

A tandoor is a special oven-roaster, sometimes also called a barbecue. About 10-15 years ago there was a tandoor in every home, because it was used not only for cooking, thanks to it it also heated the house.

Currently, other heating systems have appeared, so portable tandoors are now mainly used.

The tandoor is made in the form of a ball or jug; its main advantage is considered to be its enormous heat capacity. Moreover, such a stove consumes a very small amount of fuel.

We heat the tandoor

In the case of fuel combustion with a thermal cover installed, air can flow both through the top hole and through the loading hatch. If it enters the oven only from below, the temperature inside it will be significantly lower. This is explained by the fact that the air enters cold and does not have time to warm up. In the case of a closed blower, the combustion air will come from above. Its temperature will rise, which will accelerate the accumulation of heat in the tandoor.

The smoke is removed through the chimney. Its length and diameter must be selected based on the conditions of the required traction parameters. If the pipe is selected correctly, smoke should come out of it when the loading hole is open.

Purpose

A hood is needed for the tandoor to work properly. Its main purpose is to quickly remove smoke from the room generated during operation of the device.

The hood also allows for high-quality ventilation. And its last most important feature is the creation of conditions for better traction. Thus, a tandoor works better with an umbrella, which perfectly attracts clean air, removing smoke, which improves the functioning of the stove.

As for the design, a tandoor hood can be simple or very beautiful, decorated in an oriental style. If a stylized model is chosen, it will also help to dilute the design, create an accent, and draw attention to a unique oriental attribute.

Tandoor in the Uzbek way: step by step progress

The optimal way to make an overseas stove with your own hands involves the use of improvised means - a wooden barrel. It will allow you to easily achieve the required cylindrical shape of the product. It’s good if you can choose an option made of oak.

To use it in construction, the barrel will have to be prepared. The item selected is slightly larger than the expected finished oven. It is convenient to do the preparation while the clay mixture is “ripening”.

A barrel with pre-loosened iron rings is filled to the top with water. In this way, the wooden frame lasts up to 5 days. During this period, the necessary swelling of the wood occurs. After the scheduled period, the barrel is emptied. The noticeably heavier object turns upside down.

Next, you should dry the product a little. 1 day is enough for this. The next step will be treating the inner surface of the barrel with sunflower oil.

No need to skimp on consumables. The quality of the finished tandoor for the dacha depends on the thoroughness of processing. The oiled base is left to soak for another 1 day.

After all the preparatory work, the crucial moment of sculpting the tandoor comes. To do this, it is necessary to roll sausages from the matured clay mixture, approximately 7 cm in diameter and about 50 cm long. The resulting blanks are rolled into ribbons and cut according to the dimensions of the wooden base.

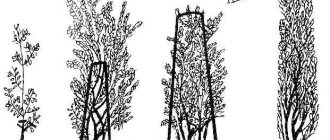

The finished strips fill the entire interior space of the barrel. They should be placed in such a way that the working material overlaps. At the same time, in the upper region of the product, not just an overlap is made, but a narrowing is simulated. This will be required for the oven to function properly. The appearance of the finished tandoor resembles a jug.

When the barrel is completely lined with clay strips, the inner surface is smoothed. The presence of unevenness is ultimately reduced to a minimum.

The final stage of making the oven base is drying the clay walls. This process will take approximately 1 month (subject to weather conditions). To do this, the barrel with clay interior is placed in a dry place with good air circulation.

The drying process is periodically monitored: the clay should gradually peel off from the wooden walls. After the drying period, the barrel is freed from the steel hoops, the wooden layer is removed, releasing the clay oven.

The finished tandoor is installed on a pre-built foundation. A fire-resistant barrier is created around the stove: brickwork is made. The tandoor itself is coated with fireproof clay or covered with a special heat-resistant solution.

The working chamber of the furnace is equipped with a grate. This will improve the airflow and functionality of the product. Installing a chimney pipe will ensure draft stabilization.

Before the first heating, the inner walls of the furnace are treated with cotton oil. The initial heating of the furnace is carried out within 24 hours. Only a combination of actions will ensure reliable operation of the structure in the future.

Step-by-step manufacturing technology

When using brick, a standard-sized tandoori barbecue weighs more than 450 kg. The structure is prefabricated and not monolithic, therefore it is sensitive to the forces of frost heaving - cracks may open when the soil moves.

First, the base is strengthened, a monolithic reinforced foundation is laid, then a combustion chamber of complex configuration is laid out from fireclay. Next, the tandoor is coated with clay from the inside and outside, the outer masonry is constructed, and the space between it and the fireplace is filled with fireproof material.

Base and foundation

Before installing the tandoor at the place of operation, you should ensure that the soil underneath is absolutely still:

- completely remove the arable layer rich in organic matter (depth 0.4 - 0.6 m);

- replace part of the clay soil with non-metallic material in which frost heaving forces do not occur (usually crushed stone);

- separate the crushed stone from the soil with geotextiles to prevent mutual mixing of these rocks;

- compact the non-metallic material layer by layer with a vibrating plate or manual rammer.

A foundation 7–15 cm thick is poured into the formwork after laying two reinforcing mesh. The lower one is placed on concrete or polymer pads 2–5 cm thick, the upper one is on special stands (spider, table) curved from reinforcement.

Attention: After pouring, the concrete is compacted using a bayonet or the tip of an internal vibrator.

Laying the inner chamber

Fast cooking of meat in a tandoor is ensured by high temperatures. There is virtually no heat loss here, which is good for the dish, but bad for a structural material operating in extreme conditions. Therefore, if a homemade electric tandoor barbecue maker consists entirely of fired ceramics, fire-resistant bricks should be used for a homemade hearth.

The easiest way to build a tandoor yourself is to use a barrel-shaped hearth:

- a board is attached in the center of the foundation;

- a template is installed on it, rotating on a central axis;

- The “barrel” is laid out in rows of bricks lying down or on an edge with constant control of the geometry of the inner surface using a template.

A cast iron grate is installed between the first and second rows of masonry, and an ash pan door is built into the bottom row, through which fuel combustion products are periodically raked out.

There are tandoor options with a separate chimney. In this case, the brick pipe (laying 1.5 x 1.5 bricks) rests on the foundation, and the side channel from the hearth is inserted into it at the level of 3 - 4 rows of masonry above the grate. The chimney height is at least 1.5 m to ensure draft.

An economical option is to lay it on edge, when the bricks in the rows are oriented vertically, with the wide part inward and outward. If you turn it with a poke, by default the spatial rigidity of the structure will increase, but the consumption of structural material will also increase.

For beginners, we recommend traditional laying with a spoon in a ring in the form of a well, but not from a single stone, but from halves. This will make it possible to achieve a smoother internal surface, reduce labor costs during coating, and ensure normal spatial rigidity. The convexity and concavity of the tandoor are created by changing the diameter of adjacent rows of masonry, which is very easy to control, even without special devices.

Instead of refractory bricks, it is allowed to use burnt ordinary stone, which is considered a defect in normal production. However, it is difficult to obtain it in the required quantity for a whole standard-sized tandoor.

Pug

The video shows the masonry coating process in detail. To do this, you should use special dry clay mixtures for laying stoves. They contain modifying additives that ensure the plasticity of the solution and workability. The coating technology looks like:

- internal surface - manually or with a grater after wetting the brickwork, the solution is applied in small portions, smoothed over the surface in a layer of 1 - 2 cm;

- the outer side is made using classical plastering technology with simultaneous mesh reinforcement.

External coating is more complex:

- the spray is applied without leveling with a ladle or trowel;

- after the 15-minute interval required for the solution to begin to set, a steel wire mesh is pressed into it evenly;

- the upper part of the mesh is bent inward to the outer surface of the masonry;

- if necessary, the wire is trimmed to ensure the specified configuration;

- The main plaster layer is applied on top of the spray layer and leveled with a trowel;

- The last leveling layer is applied manually or with a poluter to give the final configuration to the inner surface of the tandoor and equalize the thickness.

Construction of a roof or canopy

The design of a tandoor in a dacha is more reminiscent of an oven than a barbecue, so the fire safety of the structure is quite high. When making a canopy for this fireplace, the following factors should be taken into account:

- when using a thermos design, the outer brickwork remains practically cold;

- The external dimensions of the structure are small, so only corner posts are sufficient, which do not interfere with cooking meat over coals.

The size and shape of the roof is always an individual decision of the owner. There are solutions for exhaust umbrellas, the diameter of which is slightly larger than the tandoor. In this case, the hearth is protected from precipitation, combustion products are removed by the chimney, but there is no full-fledged roof as such.

Thus, a home craftsman alone can make a tandoor with his own hands and increase the comfort of using the fireplace with a canopy or roof. You just need to maintain the specified dimensions and follow the recommendations of experts.

Barbecue equipment

Unlike the barbecue oven and grill, which are often found in summer cottages, the skewers are installed vertically. Therefore, a ring of steel sheet is placed on top of the masonry or under its last row:

- the configuration follows the shape of a tandoor;

- the outer diameter is equal to the outer edge of the brickwork;

- the internal diameter is 5 - 15 cm smaller than the similar size of the tandoor, depending on its spatial shape.

These requirements arise from the design of the tandoor and the method of cooking meat on skewers. For example, if the hearth has the shape of a well, the kebab with meat should hang at least 2 - 3 cm from its inner walls. For a jug-shaped tandoor, you can use a ring with 3–5 cm slits.

Note: Some foods will soften as they cook. To prevent the portions from flying off the skewer, 2 holes are drilled in its lower part into which a U-shaped retainer pin is inserted.

The lid for the tandoor must be shaped to ensure the tightness of the fireplace after installing skewers inside it. Unlike a barbecue, they do not need to be turned periodically, since the temperature in the combustion chamber is constant and evenly distributed, there is no open fire.

Less convenient options for devices for fixing skewers are rings and rods on which the skewers are attached with hooks in their upper part. This design is lowered into the combustion chamber and removed from it as an assembly, which is inconvenient for large quantities alone.

Uzbek model: economical and practical construction

The version of the stove invented by the Uzbeks is suitable for particularly zealous owners. A single addition of fuel will allow the cooking process to take place within 3 hours. Creating a design takes time, but does not require significant expenses. Thanks to this technology, it will be possible to create a stationary or mobile tandoor.

The Uzbek stove model can vary significantly depending on the wealth of the owner and the region in which it is used. The main material for making the structure is clay. There are special fittings inside (inserts made of kaolin or refractory bricks).

A pitcher-shaped clay tandoor is the most economical choice. It allows you to be as careful as possible with fuel consumption.

How to install a barbecue area in the country

The barbecue area is a favorite place for the whole family to relax, of course, if it is properly equipped. Possible options:

- Open area - a spacious open-air area.

- Closed - is something like an outdoor room, comes with a canopy and a roof. The role of walls can be performed by wooden slats or curtains.

- Universal – frame stationary and portable options. The frame materials are metal or wood.

- A patio is a courtyard closed from prying eyes that looks like an open room or veranda, one wall of which is adjacent to a residential building.

The first thing you must do is to choose the right location for the barbecue or tandoor, taking into account the size of the site, the proximity of the site to the house, and the quality of the surface. If there is little space, you can opt for a compact corner gazebo; for spacious areas, a large barbecue area consisting of several valances (gazebo, barbecue, etc.) is ideal.

Design features of the kebab tandoor

In general terms, a tandoor is a fireplace in a pit (underground) or inside a barrel (above ground), but made of fire-resistant material (usually ceramics).

In stores, ceramic hearth bowls are expensive, so a tandoor for a summer house in 90% of cases is laid out from refractory bricks (inner barrel-shaped part) and finished with facing stone (outer square cabinet).

A barbecue tandoor has a small diameter and is practically not suitable for baking flatbreads, but it saves space in a recreation area or summer kitchen. Coals are made in the hearth or used ready-made in a package. The upper part of the hearth is closed with a lid to increase the efficiency of the oven and quickly prepare dishes.

home

Studio "Free-meN" produces:

all kinds of barbecue complexes and single barbecue stoves, fireplaces for gazebos, professional barbecues for restaurants and cafes, quick-assembled canopies and gazebos, special furniture for the summer kitchen, as well as various accessories for the main products.

We have been working in the market for more than 18 years and have extensive experience in the production of complex stove complexes and professional barbecues. The company uses special technologies that ensure high strength of structures, significantly lighten their weight and reduce installation time. Our barbecues, barbecues and fireplaces are reliable and fireproof. Various components are provided for them (skewers, skewers, grill grates, ash pans, etc.) Our gazebos and canopies are practical and durable. All products are guaranteed.

Products are manufactured in workshops by high-class professionals, and then delivered and installed in a few hours. Barbecue complexes and fireplaces can be finished with almost any materials (in particular: brick-like clinker tiles, decorative plasters, porcelain stoneware, natural stone or substitutes).

The area of operational customer service is the Moscow region and its neighboring regions . We also carry out orders for clients from other regions. Our products are installed in various regions of Russia. For remote regions, we also supply complexes without finishing, which can be independently assembled and finished to your liking. Installation instructions are provided.

The main types of our products are briefly presented below. You can obtain more detailed information in the relevant sections of the site.

Barbecue complexes

The complex can have an angular or linear configuration and include any of the elements: a grill, a cauldron stove, a smokehouse-oven, a module with a tandoor, an analogue of a Russian stove, cabinets with a sink .

At the client's request, kitchen appliances (dishwasher, refrigerator, electric stove) are built into the cabinets.

We supply various components for the complexes: mechanical or electric spit, skewers with stand, grill grates, ash pan, cauldron, built-in smokehouse, etc.

You will find many examples of complexes and information about them in the sections: “Barbecue complexes” and “Photo gallery (barbecue complexes)”.

Single barbecue ovens

Single barbecue ovens have different designs.

The upper part of the grill (main umbrella) can be separate and hang on chains or rest on poles. As standard, the grill is equipped with: a holder-stand for skewers (with the ability to adjust the height), a sandwich pipe in the basic finish and a small umbrella for the pipe.

If desired, the barbecue is also equipped with: an ash pan, a spit (mechanical or electric), a slider for adjusting draft, a shield for the brazier or removable doors (with or without heat-resistant glass), grill grates, and a built-in smokehouse.

Many examples of barbecue grills and information about them are presented in the sections of the site: “Single barbecues” and “Photo gallery (single barbecues)”.

Fireplaces for gazebos

Fireplaces can be independent or part of barbecue complexes.

The special design of fireplaces lightens their weight, makes them very durable and allows them to be finished with a variety of materials to suit the customer’s taste. During operation, charcoal or firewood is used.

The firebox part is lined with fireclay bricks or a cast iron firebox is mounted in it. In the first case, the fireplace can also be used as a barbecue for preparing barbecue dishes. Our products are fireproof and can be placed close to the wall. They do not need heavy foundations.

You will find photographs of fireplaces and other information in the section of the site: “Fireplaces in the gazebo”.

Professional barbecues for restaurants

Increased demands are placed on professional barbecues, since they operate almost continuously.

Our technology for grills and barbecue ovens is designed for such loads. Some barbecues are finished on the outside with forging or covered with modern finishing materials.

Many options are offered for barbecues: smoke filters, frying grates, skewers and skewers, electric drives, fan, etc.

Photos and detailed information on professional barbecues can be found in the “Grills for Restaurants” section.

Canopies and gazebos, quick-assembled

Our gazebos are reliable, practical and can be installed within one day.

Their frame is made of metal. Posts with a cross section of 100x100 mm and truss structures made of profiles provide high strength. Along the perimeter of the roof there is an ornament of forged parts. At the base of the pillars there are wider columns finished in porcelain stoneware. Forged gratings or panels finished with clinker or wood can be attached between the columns.

Various materials are used for roofing: metal tiles or primed iron sheets, soft roofing, polycarbonate.

The gazebo/canopy is equipped with snow retainers and ebbs. The sizes of the gazebos vary. If necessary, the structure is made taking into account the placement of a barbecue complex in it.

Photos of gazebos/canopies and other information on them are presented in the section “Gazebos and canopies”.

The same section presents the gazebos of our partners :

Where to install a country tandoor: a gazebo or veranda under a canopy

open areas with a stone base are suitable for installing the stove , and it would be nice with an additional elevation.

Cooking in a tandoor involves working with an open fire, which rises to 1 m . There should be no vegetation, wooden structures, or other foreign objects within a radius of approximately fifteen meters

A mobile or portable tandoor can be brought into the gazebo or onto the veranda where the participants of the meal have gathered, in order to distribute portions to everyone there. But this is only allowed after the coals have burned out and died out .

Varieties

There are several classifications of hoods.

Material

Based on the materials, the following can be cited:

- stainless steel hoods;

- black steel hoods;

- copper umbrellas;

- galvanized copper and steel.

Combinations of these materials are more common. Copper looks good, expensive, and stylish, but it often covers only the top layer of the device.

Mounting method

The following classification is based on the method of attaching the umbrella:

The island is fixed from above, the mount leads to the ceiling. The wall-mounted one, accordingly, is fixed at the level of installation of the umbrella to the nearest wall.

Form

Possible problems

The brick tandoor is the most difficult to manufacture. Only a person with experience in building stoves can do it on their own. If there is none, it is better to entrust the work to Asian stove makers.

It is somewhat easier to make a country tandoor based on an existing frame , for example, an iron barrel.

But even there it is necessary to follow the technology to avoid cracking of the furnace, especially for mortar.

Creating a foundation

The first step is to create a good foundation for our stove. To do this, excavate the site; it is necessary to remove soil approximately the depth of a spade bayonet. Then add a 5 cm layer of sand and compact it well.

After we mix the concrete mixture and pour it, then it should be leveled using the rule. To improve the strength characteristics of concrete, we advise you to leave the base for 2 weeks.

After a day, it is necessary to build a small structure from slats (boards) and plastic film. We need such a structure to protect the foundation from precipitation.

Building a tandoor on your own

I would like to say a few words about the construction of a tandoor. Like all types of ovens, it requires certain knowledge and skills or simply following the instructions. If you don’t want to take risks with construction, then you can always buy a ready-made option. We'll talk about prices a little later.

First, I would like to provide video instructions from Alexey Kandalov , who showed step by step the construction of a tandoor in his dacha. I suggest adopting someone else’s experience and studying their approach to this process.

Foundation

A small monolithic platform made of concrete mortar is used for the foundation. It is made with reinforcement, in this case massive steel rods are used.

Bricklaying

Fireclay bricks and refractory composition for furnaces are used for construction.

The width of the lower internal base is 60 cm, and the upper one is 40 cm. The masonry is made in three layers.

Thermal insulation

To preserve heat, the outer surface is sheathed with mineral wool (ursa), then pressed with mesh and finished with mortar.

Final finishing, firebox and decoration

A practical ready-made tandoor must be supplemented with a metal grid on top, on which skewers with food will be hung. Additionally, it is necessary to make lids to retain heat (during cooking) and protect from rain.

Finally, a little decoration never hurts. The owner decided to use shells.

Drawings with dimensions

As it turned out, building a tandoor is even easier than finding decent drawings for it. We selected the project, installation diagram, as well as the dimensions of all its components. Pay attention to the upper and lower diameters, as they are different for all masters.

see also

Comments 92

It is a masterpiece! Five points!

Three years have already passed. The flight is normal. Everything suits me. In addition to aesthetics, there is also functionality...

This is really a barbecue! Five points! good luck to you!

What a thing!

Yes, I did what I had to do!

Gorgeous! Even without coals in the grill, my stomach was already growling!)

So everything was done correctly!

you can immediately see a person from Central Asia))) the tandoor does not look like an Asian tandoor, really.

Well, just a bomb!

It actually turned out good!

I myself cook a lot over the fire, experiment with various barbecues, and have built several myself. There are many projects spinning in my head, but unfortunately there is very little time. And your grill is very competent and thoughtful, but operation will show!

Amazing!