Briefly about the need to process grass and branches

The garden owner does not need to explain why he needs a shredder. After each sanitary, rejuvenating pruning of fruit and berry bushes and trees, mountains of branches accumulate. A shredder is needed to grind them.

Farmers and gardeners also need a shredder. It is used to process different types of plant materials:

- potato tops, tomatoes;

- stalks of corn, sunflower;

- grass, leaves.

The chopped green mass is used as livestock feed and poured into compost heaps. Large fractions of branches are used instead of firewood, medium and small fractions are used as mulch and raw material for composting.

The nuances of operating homemade equipment

A self-made shredder is essentially three in one: a chopper for branches, a straw cutter, and a mechanism for cutting grass. It helps to significantly facilitate household work associated with the disposal of plant waste, as well as feeding poultry and livestock.

If you have to process grass in small quantities, for example, for chickens, geese, ducks, then very simple devices that operate on human muscle power, for example, a hand pruner, are sufficient.

For homemade electrical equipment, it is recommended to install a separate differential circuit breaker to provide reliable protection against electric shock in case of unforeseen circumstances. In any case, when making a garden shredder yourself, you must follow safety regulations. It is also worth adhering to them during operation of the mechanism. Before working with equipment, it is recommended to wear goggles, suitable protective clothing and check that the structural elements are securely fastened. When creating a home-made unit, you should take into account the upcoming amount of work, as well as the nature of the vegetation being processed, in order to select an engine of the required power and the desired design of knives. This will allow the completed device to cope with the assigned tasks without any problems.

Shredder design for branches and grass

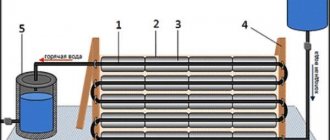

The purpose of the unit is to quickly and safely grind plant debris. The main function is performed by the cutting block. The knives are driven by the engine directly or via a belt drive. The units are installed on a stable frame. The moving elements are covered with a casing. Two compartments are made for feeding branches and unloading chips.

Metal frame

A homemade shredder with a powerful electric or gasoline engine needs a stable, durable frame with space to install the engine and a rectangular support for the cutting unit.

To make the shredder frame use:

- profile pipe 25;

- corner at 30;

- channel.

Fasteners:

- ears for the engine,

- nuts,

- hairpins.

Engine

Full autonomy, work anywhere in the garden, independence from the outlet - the advantages of a gasoline engine. A homemade shredder for processing branches, tomato tops, and grass is equipped with a motor from a motor-cultivator or walk-behind tractor with a capacity of 6 liters. With. It is moved from one unit to another.

You need a gearbox that provides 90° rotation if the gasoline engine has a horizontal shaft and the chopper has a vertical shaft.

Electricity costs are lower than gasoline, so if there is a network on the site, an electric motor is installed on the unit. To chop branches 2-3 cm thick, a 3-phase electric motor of 2200-3500 W is sufficient. When making a low-power grass cutter, they take engines from household devices. They are removed from washing machines and vacuum cleaners.

Knives

The thickness of the branches processed by the shredder depends on the design of the cutting unit. In home-made designs, several options are implemented:

- to grind branches with a diameter of 7-8 cm, several cutters are installed on the shaft;

- hammer-type cutting block for grinding thin rods;

- the universal cutting mechanism is made of 15-30 circular saws mounted on a shaft;

- knives from factory garden equipment - brush cutters, lawn mowers;

- chop grass - trimmer line;

- stump crusher from a plane;

- two shafts with 3-4 steel knives for cutting branches of bushes and trees.

Homemade knives are made from springs.

Protective cover

To prevent chips from flying around, you need a protective cover. It is made from sheet steel with a thickness of at least 1.5 mm. Tin is not suitable for this purpose. During active use of the shredder, it quickly becomes deformed from strong impacts of wood chips.

Container for receiving sawdust

Old shopping bags, boxes, buckets, and bins are used to collect small garbage. For powerful units, the bunker is welded from steel sheets and riveted from galvanized steel.

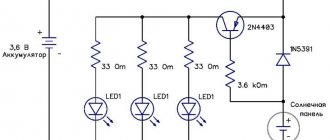

Electrical wires and start/stop button

To turn on and off a homemade unit, use a push-button station designed for the appropriate current. Its purpose:

- turning off and turning on electrical equipment;

- changing the direction of rotation (reverse).

To connect the engine to a three-phase network, you need a five-core flexible copper cable in double insulation; for a single-phase household network, a three-core cable is sufficient.

Differences from straw cutter

A grass cutter and a straw cutter are similar in many ways and work on the same principle .

The difference between them is that the first is a small household device optimized for chopping freshly cut grass, while the second is a powerful unit that works most efficiently with straw.

The most effective modifications of straw cutters are mounted and trailed units, because they can take a whole roll (bale) of compressed straw at a time.

The most effective grass cutters are small devices with interchangeable blades of various shapes, because by installing one or another cutting tool, they can be optimized for a wide variety of materials.

Necessary materials

To make a garden shredder with your own hands, you need time, tools, and materials. Homemade will not be cheap when you have to buy everything. The costs will be recouped if the cost of the unit you make yourself is 3-4 times less than the factory equivalent.

Engine

The engine power determines the thickness of the processed branches and the duration of continuous operation.

| Power | Rod thickness |

| 1500 W | up to 2 cm |

| 3000-4000 W | up to 5 cm |

| from 6000 W | 10 cm |

The presence of a three-phase electrical network is a prerequisite for the operation of powerful electric motors.

2 pulleys

Bearings, sprockets, gears, pulleys are selected so that the gear ratio provides the required rotation speed of the main shaft. The optimal value is 1500 rpm.

If the electric motor has 2800 rpm, then to reduce the value to 1400 rpm. install two pulleys of a certain diameter:

- slave - 200 mm,

- leading - 100 mm.

It is more profitable for V-belt transmission to grind pulleys into 3-4 grooves. By rearranging the belt, you can adjust the speed.

Circular saws or cutters

To make a high-quality package 6-10 cm long, take 15-25 cutters or saw blades. The axle is selected according to the bore diameter; if the discs have a diameter of 20 mm, then use an M20 stud. To prevent the teeth from catching during operation, homemade plastic washers are inserted between the discs.

2 bearings

A pulley is put on the M20 stud axle. The part is taken from a VAZ generator and pump. To ensure rotation there are 2 bearings. The internal diameter of the parts is 20 mm.

Profile pipe in meters

The cutting unit, consisting of an axle and circular saws, and the engine are mounted on a frame welded from profile metal pipes. The size is determined taking into account the dimensions of the nodes. The motor and the shaft with circular saws must be spaced apart from each other.

The longer the belt, the lower the transmission efficiency.

The thrust block is made of a metal profile and welded to the frame.

Sheet metal for body and hopper

The body is made of iron sheet 5 mm thick, this material is the most reliable. The container with a socket for feeding branches is made of galvanized steel; it is flexible and meets the technical requirements for this structural element. The frame is made of pipes or channel. The height is calculated based on the height of the operator.

Popular models

We have collected in one table the most popular grass cutters that can be found in regular or online stores:

| Model and link to the manufacturer’s or seller’s website | Cost thousand rubles | Quantity of chopped grass kg/h | Engine power kW |

| IKB-003 | 4,6 | 150 | 1,15 |

| IKB-002 | 3,5 | 150 | 1,15 |

| KR-02 | 3 | 150 | 1,2 |

| DKU-05 | 5,2 | 50 | 0,75 |

| Farmer KR-01 Miass | 14,5 | 200 | 1,1 |

Do-it-yourself branch chopper: drawings

A ready-made technical solution is taken as a basis, a drawing is constructed taking into account the dimensions of the available parts. To reduce labor costs for fitting components, the diagram indicates dimensions, mounting holes, and welds.

A do-it-yourself wood waste crusher is made according to the following drawings:

- Diagram of a simple homemade shredder powered by an electric motor.

- Stationary rotary chopper. In this model, the functions of a cutting tool are performed by a disk cutter with 4 knives.

- Drawing of a two-roll shredder. This product has a self-grabbing function. When the shafts rotate, the knives mounted on them easily cut branches. Waste size is 2-8 cm.

- Device for grinding grass. Drawings of a grass grinder and a diagram of the assembled device.

Application in subsidiary farming

This device can grind:

- hay;

- straw;

- waste of vegetables and fruits;

- fallen leaves;

- sunflower cake.

A grass cutter is indispensable in a subsidiary farm, because with its help you can prepare food for birds or animals, as well as prepare materials for subsequent processing.

By changing the distance from the knife to the outlet, as well as the size of the latter, you can even turn this device into a grain crusher , that is, a device for grinding dry cereals.

Grinder grinder

The simplest homemade product can be easily made from a grinder. It is better to take a tool with a power of 3000 W.

Design examples

The frame is shaped like a kitchen stool; it is welded from a metal corner 35 × 35 mm. A grinding machine is attached to it from the bottom with the shaft up. The working container is made from a bucket, tank, or gas cylinder.

Cut two holes:

- the first is round, in the middle of the bottom for the angle grinder shaft;

- the second is rectangular (5 × 10 cm), on the side for waste disposal.

To prevent wood chips from scattering, a tin pipe is attached obliquely to the side slot. A two- or three-blade knife from a lawn mower or a disc from a hedge trimmer is attached to the shaft of the grinding machine.

Assembly drawing

If you have sheet steel, fittings, angles, welding, then a drawing of a compact device for chopping plants will be useful. Assembly sequence:

- 2 plates are cut out of a sheet of steel, one for fastening knives and tools, the second for the hopper lid;

- a hole is drilled in the center of the first plate, a washer is welded, the edges are welded with a corner, 2 studs are welded on the sides;

- fastenings for the grinding machine are welded on the outside;

- a hole is cut out in the upper part of the second plate, a piece of pipe is welded obliquely or horizontally;

- the finished hopper lid is secured with nuts to the studs;

- make legs from reinforcement;

- attach the grinder, put a knife on the shaft.

A do-it-yourself grass and twig chopper for your dacha, made according to this drawing, will be useful in the household.

Principle of operation

In terms of their operating principle, these devices are closest to lawn mowers.

The rotating blade creates an air current that draws in vegetation and prevents it from flying away.

When the grass reaches the knife, it cuts it into pieces of various lengths, after which the vortex flow carries the cuttings with it and removes it from the body of the device.

The difference between both types of devices is that lawn mowers move above the grass, so the body of the device presses the vegetation to the ground, and the air flow lifts it to the level of the knife, while the grass cutter stands still, and the material is poured into it from above.

What kind of device, scope of purpose

As soon as the first rays of the spring sun warm the earth, gardeners go out to fight excess vegetation on their site, which interferes with the development of useful crops.

But weeding, thinning, and cleaning dry leaves and grass ends up cluttering the area with garbage, which not only spoils the appearance of the landscape design, but can also cause numerous plant diseases.

What to do in such a situation? Leaving garbage is unacceptable, and burning it is a risky business due to the introduction of a ban on burning grass within city limits according to the new Russian legislation.

It is unprofitable to remove garbage at your own expense, and it is a pity to lose raw materials for such valuable compost. And here a unit such as a chopper becomes simply irreplaceable, which will simultaneously solve all problematic issues.

A garden grass shredder is a new word in agricultural technology that makes it much easier to work on a plot of land and forget about the headache of getting rid of unnecessary grass. Representing a container with a number of blades and a powerful motor, this unit is capable of grinding any herb in a matter of seconds.

Weeds, thorns, dead wood, leaves and other debris are processed into fine compost, which no longer takes up much space, but is stored for further use as fertilizer for garden beds.

If you do not need to fertilize the site, it will not be difficult to pack excess compost into bags and remove it from your territory, which was simply impossible with those piles of plant debris that were weeds before processing.

If wood chips are processed, they are often used as fuel. Wood chips, processed through a grinder, are formed into pellets and become an excellent type of heating fuel, replacing firewood and coal. If you wish, you can form pellets at home.

Thus, there are many advantages from purchasing a shredder, which is why it has gained worldwide popularity and is becoming increasingly in demand in our country, not only in large farms, but also in private landholdings.

Potential tools for manual labor

Some owners who are not afraid of hard work still use hand scythes. As a rule, the tool helps to get rid of grass that is intended for hay. Some owners level their lawns with it. There are several varieties of hand braids.

- Lithuanian. This is the most famous option with a straight and long handle and the same blade.

- Pink salmon. It has a curved handle that helps get rid of grass in hard-to-reach places and in areas with difficult terrain.

- Serpan - mini braid, serpan braid. This tool has a short blade and the same handle. It is designed to remove plants with hard stems and branches (clumps of grass, bushes, etc.).

It will be difficult for an untrained person to work even with a familiar tool. It takes time to get used to it. How do you mow the grass?

- With your left hand you take the scythe above the handle, with your right hand - by the handle.

- The right leg is placed forward for support, the left one is slightly back.

- Make circular swings, moving from right to left. They try to keep the handle on the belt line.

- The body is tilted and rotated slightly during operation. The blade's nose is raised off the ground to prevent it from touching the ground and to ensure an even cut of the grass.

When working with a hand scythe, it is very important to exercise maximum caution, because with a sharp tool it is easy to injure not only yourself, but also those around you.

What else is worth paying attention to

When choosing a shredder, you should pay attention to the following points:

- How convenient is the receiving hopper? Different models offer their own receiver design: it can be located at an angle or vertically. Premium models allow you to adjust the position of the receiver. Choose the option that will be most convenient for you for your work.

- The kit should include a pusher, which greatly facilitates the work of loading plant debris.

The lack of a pusher in the model can lead to serious injury because pushing grass into the shredder yourself is dangerous.

- If you are looking for a unit that will make your work as easy as possible, then pay attention to models that are equipped with guide ribs. At the same time, some models have a cross-shaped or slot-shaped receiver - such technical features improve the operation of the unit and make it easier to load large volumes of grass, as well as branchy branches.

- Mid- and premium-class options are usually equipped with a function for differentiating the output raw materials. This becomes very convenient if, for example, you need one fraction of raw materials for compost, and another for the formation of pellets for stove heating.

- Removable bags and a translucent hopper for waste grass can be considered as useful additions.

In addition, many modern grinders are equipped with a mechanical system for automatically feeding waste raw materials into the hopper. In this case, the work is done extremely simply, you just need to lower the plant debris into the funnel, and the device will do the rest for you.

A useful feature is also the ability to adjust the speed of rotation of the knives (or line), this becomes especially important when you need to adjust the type of raw material being processed.

Device

At the moment, there is a wide variation in the choice of shredder models, but despite this, their design principle is similar, the difference lies only in the size of the device and optional features.

A standard shredder has the following structure:

- Metal body. An important condition for a shredder is its reliability and durability, and therefore heavy-duty metals are used for its manufacture. Polymers can also be used to produce the body of the unit. Often the body is mounted on a frame equipped with wheels. This is done to make it easier to move the device around the land plot.

- The heart of a shredder is its motor. This can be an internal combustion engine or an electric motor.

- The grinding process is carried out through a cutting mechanism powered by a drive.

- To make loading grass and leaves a simple matter, the unit is equipped with a loading bowl or, as it is also called, a loading hopper. As a rule, the bowl has the shape of a funnel, which makes it much easier to load plant debris into the shredder.

- The device also has a receiving hopper where the processed plant mixture is supplied. You can attach the bag to the receiving hopper, so you don’t have to waste time on arranging the mixture, or you can directly throw the mixture away during processing in the areas of your garden you need. There are models that allow you to adjust the direction and height of spreading the crushed mixture, which is also very convenient and saves time on gardening work.

Garden Shredder Power Type

You need to pay attention to this parameter first of all, because a lot depends on the type of power supply of the device: its power, capabilities, comfort of use and the need for maintenance.

Shredders are divided into two types based on the type of power supply.

Electric garden shredder

The optimal choice for owners of summer cottages. The productivity of such devices is quite enough to process ordinary plant waste: vegetable peelings, last year’s grass, trimmings of branches and grape vines.

Their power usually does not exceed 2.5 kW, and the noise level is much lower than their gasoline counterparts. To operate, they only need a connection to the electrical network, but it is important that the wiring is in good technical condition. They do not smoke and do not require regular maintenance. However, their capabilities, as a rule, are limited: when trying to chop a large branch, the device may fail.

Gasoline garden shredder

It will be the right choice if the site is not connected to power supply or there is a need to purchase a powerful, “omnivorous” unit. The motors of gasoline shredders can have low power, close to electric ones. And they can provide exceptional performance, which will be sufficient for chopping thick branches and twigs.

In operation, such a unit is more demanding: it requires regular maintenance and requires monitoring the oil level. But by refilling the tank on time and not forgetting to carry out maintenance, you can safely move the shredder around the site without being “tied” to the outlet. And work with it for many years: gasoline engines usually last longer than electric ones.