Having your own artificial pond is an incomparable pleasure from swimming and an opportunity to cool off on a hot summer day. However, even a small hydraulic structure requires significant maintenance. The cost of filtering devices in specialized stores is quite high, but you simply cannot do without them. Therefore, many people think about how to make a sand filter for a pool with their own hands, so as not to overpay and at the same time achieve high efficiency.

Is such equipment necessary?

Of course, those who have very small stationary or inflatable structures do not have to deal with the issue of water filtration. After use (bathing), it is simply used for household needs and watering cultivated plants on a personal plot. When necessary, the container is refilled - and no problems. However, this is only relevant for small tanks.

Despite this, even a small artificial reservoir can cause certain difficulties for its owners. After draining the liquid, the surface should be washed, only then fill the mini-pool again. Maintenance is a rather labor-intensive process, and in the summer you want to freshen up more than once a day. What can we say about children who are ready to splash in an artificial pond around the clock?

Without proper care, water quickly becomes polluted. Harmful microorganisms and bacteria multiply in it. After some time, a distinct unpleasant odor and green color appear. Swimming in such conditions is unsafe.

In addition to contaminants entering the aquatic environment due to human use, standing liquid becomes a haven for:

- dust particles;

- leaves and grass;

- bird waste products;

- pollen of plant origin.

The presence of these unwanted elements is eliminated using special nets and water vacuum cleaners. However, complete cleaning is not possible with these devices. Most of the substances entering the water dissolve or remain in it in the form of suspensions. That is why it is necessary to clean not only the surface and sediment, but also the liquid layer itself.

Water preparation devices for food

You can clean dirty liquid at home with homemade filters. The resulting product does not always satisfy all requirements. Only the use of high-quality elements allows you to achieve the expected results. They retain mechanical, chemical and bacteriological impurities.

At the dacha they use several types of homemade filters:

- flow-through coal;

- submersible for technical water in an aquarium, swimming pool;

- external, allowing you to get rid of mechanical contamination.

A homemade system is used when it is necessary to coarsely filter water from a well, well, or rainwater. Fine cleaning is used to eliminate odors caused by the presence of bacteria.

Simple filters for home made from plastic containers

There is no better absorbent for a homemade device than activated carbon. It does not allow mechanical impurities to pass through, as well as many toxins and bacteriological harmful substances. For production, dishes with a sealed lid and plastic pipes are used. For a small aquarium, disposable syringes are suitable.

The main thing is that the volume allows you to accommodate the required amount of filter material in several layers. The manufacturing process of the simplest device occurs in the following sequence:

- 1. Take a plastic bottle or other similar container, in which the bottom is cut off. Below, at a distance of about 2 cm, 2 holes are made with an awl.

- 2. One 10mm hole is also drilled into the lid. Alternatively, many small ones are pierced.

- 3. Screw onto the bottle and begin laying the cleaning material. Natural fabric or ready-made filters, lutrasil, are used on the bottom and walls.

- 4. Next comes activated carbon. On top there is clean sand, then gravel, which alternate in several layers. The total volume should not exceed 2/3 of the container's capacity.

- 5. Cover everything with a cloth that will not allow large particles to pass through. They hang it up and fill it with water, wait for it to be cleaned and poured into a clean container.

The system has a disadvantage: filtering takes a long time.

It is more convenient to use 2 pieces of pipe, one of which is 4 times longer than the other. The short one is used for rough cleaning. Place the lid tightly on the plastic container in which the hole is made. A mesh is placed on it and the space is filled with pharmaceutical cotton wool or padding polyester. On the other side, the pipe is also covered with a lid and mesh.

One end of the long piece, which serves as a fine filter, is prepared in the same way: a tight lid with a mesh. On the other side is the neck of a plastic container. The filter material is filled in, each layer in turn. Both parts of the structure are connected.

It’s also easy to do water purification for your home aquarium yourself. Requires 2 disposable 10 ml syringes with cut off tips. They are connected to each other, holes are made along the entire length. A tube with a spray at the end is placed inside, and if you add zeolite, the quality of the water will increase - nitrites will be removed. The outside of the device is wrapped with a sponge.

How do sand-based filtration media work?

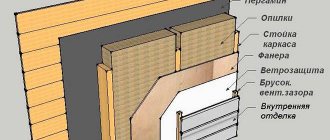

The sand filter system includes five main elements:

- a tank with a neck that can be tightly closed with a lid;

- a small piece of pipe for supplying liquid;

- drainage pipe;

- sand filler;

- a grid with a narrow cell for drainage.

The tank itself is made of stainless material (for example, plastic). Drainage cylinder made of stainless steel mesh. A water outlet tube is connected to it. The size of the cell holes should be smaller than grains of sand. Quartz or glass sand is usually used as a filter base.

Understanding the diagram of how a sand filter for a pool works, it is easy to notice that this device is extremely simple. It can be constructed from ordinary plastic barrels. A reliable lid and neck are already available; all that remains is to attach the pipe sections and assemble a drainage compartment from a suitable mesh.

Sand replacement

Ordinary quartz sand must be replaced every three years. Some purchased installations (for example, Intex sand pool filters) use sand, which requires replacement less frequently - approximately once every 5 years. The operation is not difficult at all:

- Turn off the pump supplying water to the filter.

- If you are using a factory-made filter system, close the nozzles and close the skimmer valves.

- If the filter is installed inside the pool, the water from the bath must be drained.

- Disconnect the filter from the system.

- After opening the hatch, remove all sand from the housing, not forgetting to clean the nozzles.

- Lay new sand under water pressure. As mentioned above, the bottom layer should be formed by the coarsest sand, then the material of the middle fraction is laid, and the finest sand is laid on top.

- All that remains is to close the filter cover with the latch and connect it to the system.

After each sand filter maintenance operation, be it changing the sand or washing it, check that the pressure gauge hole is not clogged with dirt or sand.

How does it function

Please note that the structure body is not completely filled with filler. There should be space between the sand base and the throat. During operation of the device, it is filled with contaminated liquid from an artificial reservoir. Water is supplied using a pump. The aqueous medium penetrates from top to bottom through a dense layer of sand, thereby getting rid of polluting particles, and is supplied back, already purified. As long as the pumping system is active, circulation does not stop.

It is easy to determine the pressure during operation of the supercharger using a pressure gauge. Data varies depending on the location of the fluid pumping mechanism:

- If it is placed in front of the treatment unit on a section of the water supply pipe, a water volume is pumped into the tank.

- When the pump is installed in the drainage part of the system, H2O is sucked out of the tank. Vacuum is applied.

During the cleaning process, the sand filtration device becomes dirty. For the purpose of washing, a liquid medium is supplied in the opposite direction. Clean water flows into the container from below, and contaminated water coming out from above is drained.

How does the device work?

The pump, gearbox, pipes and pipes leading from the pool and back to the bowl are connected in such a way as to form a closed water flow system.

The pipe through which water is drawn from the pool is mounted in such a way that it is drawn from the surface of the tank. The water intake and return pipes to the pool must be located relative to each other in such a way that “dead” zones do not form in the reservoir - places in which water does not circulate.

The operation of the sand filter depends on the mode:

- “Filtration”: water is taken from the pool and pumped through the sand under pump pressure. The purified water is then released back into the pool.

- “Back flushing”: water is taken from the tank, but pumped through the filler in the opposite direction. The waste water is then released from the cycle into the sewer system.

- "Circulation". The pump pumps water from the reservoir through the pump back into the reservoir without passing it through the filler.

This article will tell you about the operating modes of the sand filter.

Wiring diagram for a sand filter for a pool

If you want to make a water purification device yourself, you will need a blueprint for it. As a basis, you should take one of the most suitable ones based on your own capabilities and the expected volumes of liquid to be filtered.

1.5 m3/h For process water

1.5 m3/h For process water

MBFT-75 Membrane for 75GPD

Why clean the pool water?

During the warm season, water in any body of water slowly becomes polluted with organic substances if it does not circulate and is not filtered. A natural reservoir is a complex natural circulation system where groundwater flows into the ground, and its supply is constantly replenished by precipitation. In nature, filtration is carried out naturally, but in a country pool this has to be done using special devices.

Organic sediment rapidly decomposes, causing decay, and in this environment microscopic greenish bacteria grow - light blue-green aquatic plants and greenish euglena. This process is known as “water blooming,” which becomes cloudy and greenish in the light. This process is well known to aquarists, and approximately the same thing happens in a pool if there is no filtration.

In addition, plant debris falls onto the surface of the water - dry branches, ovaries, flowers and leaves. Bird feces, sand and small particles of soil blown by the wind fall to the bottom of the pool. Uninvited guests - mosquito and dragonfly larvae, falling insects (beetles, wasps, grasshoppers) are often alive and well in an unnatural body of water. Unable to get out of the water, they drown and disintegrate. This whole garbage not only spoils the water, but also destroys the aesthetics of the pool.

Tip: A filter with a pool pump will help improve the situation. The filtered water is not drained, it is cleaned and returned to the reservoir. Large plant debris is removed from the tank with a net or a special garbage container for overflowing water. Special chemical additives help prevent smoldering and blooming of water. Dirt from the bottom is removed with a water vacuum cleaner or a homemade siphon from a hose.

Features of choosing a device

Filter media are usually sold without filler. Therefore, sand must be purchased separately. When choosing a model, rely on volumetric characteristics. This value indicates how powerful the unit in front of you is. Accordingly, how well it copes with cleaning the aquatic environment. The larger the size of the artificial reservoir, the higher the power indicators should be.

When purchasing a device, be sure to consult with a specialist consultant. Pay special attention to the manufacturer. Thus, Voda Otechestva is one of the best manufacturers of water treatment equipment. Our company's products have long proven themselves to be the best on the market.

When selecting a device, take into account the features of the fasteners and the location of the font. Sand-based treatment systems are not mounted directly on the container due to their impressive mass. They are usually installed next to the tank.

It is equally important to choose the filler itself correctly. It is sold packaged in bags and is completely ready for use. The least expensive option would be quartz material. True, it won't last long. It is much more profitable to purchase a glass mixture with a long cleaning life. You can also opt for a combined form with an admixture of gravel or other additions.

Advantages of sand filtration device

Three types of filters are used to purify pool water:

- diatoms;

- cartridge;

- sand.

Diatomaceous . The best quality of cleaning and reliability of operation is ensured by the diatomaceous earth (also called diatomite) type of filter device. However, such a unit is expensive due to the use of an expensive product that performs ultra-fine filtration and adsorption, in addition to eliminating a number of bacteria.

The filter elements of the cartridge variety are the devices on which the name of this group of filters is based. This is the most convenient, but not very popular type of water purification device due to the price. True, they are more affordable than the previous ones.

Cartridge packages made from natural raw materials (fossil skeletal mass) provide high quality cleaning and neutralize most microbes, but have a high price

Cartridge devices have a simple design and can be easily disassembled for cleaning and replacing the main element. The cleaning component is a cylindrical cartridge consisting of polypropylene membranes.

Such filters have low performance, so they are suitable only for small pools. The cartridges themselves have to be washed frequently (once a day) and replaced.

Cartridge-type filters are quite compact. They are installed by the pool or directly in the tank. However, due to low productivity, they are used for small-volume pools

Sand filters can effectively serve fairly large tanks. The filter layer is quartz sand. The units have a simple design and can be assembled on your own. At the same time, the cost of the finished cleaning system will be approximately 2 times lower than the purchased one.

In addition to mechanical methods for purifying pool water, chemical agents are also used to help precipitate contaminants, after which they are simply collected with a net or similar device.

Making a sand filter for a pool with your own hands: instructions

To make a filter unit with your own hands, you need to perform a series of sequential actions. Each step is of great importance, the implementation of which must be approached with maximum responsibility.

How does it work

The operation of the filtration device is based on the mechanical extraction of suspensions from the liquid (organic particles and mineral substances). In this case, water passes through the sand base from top to bottom.

The structure body is not completely filled with sand. When closed, a tightly closed area is formed above the surface of the cleaning material, into which H2O is supplied from the reservoir. Passing through the sand mixture, it is filtered. Pollutants are retained by grains of sand. It is important to understand that the filler should be quite fine. The filtered aqueous solution fills the bottom drainage section, from which it is then fed through the drainage system back into the container.

Selecting a connection method

There are three methods to connect a filtration device:

- By installing a filter in front of the sand tank. The liquid is directed through the sand base under pressure.

- The pumping system is installed after the filter unit, which provides a vacuum vacuum in a tightly closed tank. The liquid medium is drawn into the purifier.

- The purified H2O is pumped by a supercharger installed after the purification device. But from the pool it enters the sand structure by gravity.

Cleaning agents are produced on an industrial scale according to the first scheme. They are usually equipped with special pressure gauges.

Preparing the body

To do this, you will need to select a suitable container, which can subsequently be sealed with a lid. For example, an expansion tank housing should be used. First, you will have to remove the membrane from it and paint it on the inside to prevent corrosion. A polypropylene barrel is also perfect. Such specimens are easy to find in any summer cottage.

When deciding to install a homemade sand filter for a pool, you can start from the approximate drawings according to the second and third diagrams. You just have to do some additional work with the tightness of the structure, since liquid pumping in these options is carried out by suction. If air gets into the system, it will not function fully.

Insertion of fittings and internal elements

In order for contaminated liquid to be supplied to the filtration device, and clean liquid to be pumped out in a timely manner, connecting pipes must be cut into the walls of the housing. The joining area is first thoroughly treated with a sealing solution.

A coarse filter device is subsequently attached to the embedded section of the tube. In order to make a simple water intake drainage, a plastic product with specially made holes is used. It is covered with suitable garden material. Alternatively, you can simply buy a ready-made cylinder cartridge used for purifying drinking liquid.

SF-mix Clack up to 0.8 m3/h

SF-mix Runxin up to 0.8 m3/h

SF-mix manual up to 0.8 m3/h

On one side, the cylinder is blocked with a plug, and on the other, a fitting is installed. After this, a pipe connecting the structure with the fitting is attached and placed at the bottom of the cleaning device.

Filter element

The optimal solution is to use special quartz sand. Sand grains measuring 0.4-0.8 mm ideally retain dirt. This filler does not need to be prepared or disinfected beforehand. To fill a tank for a medium-sized pool of about 40 cubic meters, you will have to purchase a couple of 25 kg bags.

Installation of parts for unit operation

Of the elements necessary for proper functioning, the following must be installed:

- Pressure gauge. A device that can be used to monitor blood pressure readings.

- Security group. Can be installed instead of the above device. Available in the form of a manifold with a meter, an air vent and a safety valve.

- Air vent. A section of narrow pipe with a tap.

Piping of the treatment system

Manufacturers make sand filtration media with built-in six-position valves. When installing it yourself, use the appropriate shut-off valves and fittings. The main thing is that in the end the filter works for washing and cleaning.

An overly powerful pumping system is not the best solution. A power of 150-300 W will be quite enough. The capacity should be selected based on the condition that the contents of the tank should be replaced within 6 hours (no longer).

Pool connection

At this stage, it is necessary to connect the drainage and water supply hoses to the fittings using clamps. If there are nozzles installed in the walls of an artificial reservoir, you can connect to them.

In order for water to circulate well, the points of intake of dirty liquid and removal of purified liquid must be placed as far as possible from each other. It is worth installing a coarse filter device in front of the pump so that the system is not damaged due to the ingress of large contaminants. If the tank is to be gravity fed, the top of the tank should be below the surface of the water in the bathing tank.

Filling the device with sand and then starting it up

When understanding the features of pool filtration according to the instructions, it is important to remember that the structure should not be completely filled with sand. Free space at the top will be required for incoming H2O. When filling the sand base, it is necessary to periodically wet it for greater density. It is strictly forbidden to turn on the device “dry”.

The initial start of the system is considered a trial start. If problems or leaks are found, they must be repaired. Keep in mind that to carry out repair work, you need to drain all the liquid in the cleaning device.

Types of mechanical filters

The most accessible method for most users is mechanical pool cleaning using simple and inexpensive devices. Such systems are often installed in frame and inflatable tanks at dachas and country houses. Mechanical water purification devices have different filter substances, and therefore are divided into:

- sand;

- diatoms;

- cartridge

Sand filter for pool

In specialized stores, consultants explaining how a mechanical pool filter works often cite the sand variety as an example. The filter element in it is different fractions of calcined quartz sand. There are also models with multi-stage cleaning, consisting of a layer of pebbles, sand and activated carbon. The pump is a container with a filtering agent into which water enters with the help of a pump, which is purified and supplied back to the pool.

The advantages of the device include:

- Low cost compared to other varieties.

- Cleaning speed. The sand filter cleans faster than all analogues.

- The degree of purification is regulated by changing the sand fraction.

The disadvantages include:

- Large volume of the device and solid weight. It is more expedient to use such structures in large artificial reservoirs.

- The need for regular cleaning or replacement of the filler. On average, once a week with regular use.

Diatomaceous Pool Filter

If fine cleaning is necessary, professionals, when advising which pool filter to choose, recommend buying the diatomaceous variety. The cartridges in such a device are filled with soil containing silicon dioxide. It is a rock formed from the remains of fossilized ancient algae in yellow-brown and gray colors. It is also called diatomaceous earth. The only significant drawback of the device is its high cost, which starts at $1000.

The advantages of diatomaceous earth filtration include:

- Subtlety of cleaning. The system is capable of trapping debris smaller than 1 micron.

- Destroys most known pathogenic microorganisms.

- Reducing the use of chemicals by approximately 80%.

- Special properties of purified water. It is popularly called silicon and is considered a good rejuvenating and healing agent.

Cartridge filter for pool

Small pools and medium-sized ponds often use a cartridge filtration system. The cleaning device contains special cartridges with a propylene membrane. The main indicator of the device is productivity, that is, the volume of purified water per unit of time. It should be taken into account along with the size of the pool when purchasing. The advantages of the device include:

- Acceptable price.

- Compact sizes.

- Easy to use.

- Possibility of installation both in the tank itself and outside it.

Among the shortcomings, users name:

- Regularly changing or cleaning consumables. The pool filter cartridge gets dirty quickly, so it must be washed or replaced regularly. Its cost is low, so many owners choose a replacement.

- Ineffective when used in large artificial reservoirs.

Required materials and tools

All you may need when making a filter device yourself is:

- soldering iron, suitable for polymers;

- hacksaw;

- strong scissors;

- drill;

- pliers;

- sealant.

But first you need to acquire the following list of items:

- suitable container with a wide neck;

- well-closing lid;

- pipe sections, clamps, hoses;

- sand base as filler;

- water intake device;

- drainage pipe;

- pumping system, valve.

Stage No. 2 - assembly of the filter structure

In general, a homemade sand filter for pools is not that complicated, you just need to do everything carefully and conscientiously. The pump power is selected according to the volume of the tank; on average, water should circulate through the filter three times a day, no less. With a pump capacity of 40 liters per minute, three cycles of continuous cleaning can easily be completed in ten hours. At the same time, it would be nice to provide a so-called power reserve, since the pool filtration system operates under pressure to pump or pump out.

So, first we prepare the container: we drill a couple of holes in the barrel that coincide with the diameters of the drives.

You can even filter water through a plastic bowl with holes made in it and wrapped in several layers of nylon. A hose is also attached to this structure, and all cracks are sealed with sealant or hot melt adhesive. Even such a primitive sand filter for a do-it-yourself pool must be equipped with a pressure gauge, which helps determine the pressure values in the system. And if it begins to exceed the permissible values, then this means one thing - it’s time to clean the filler by backwashing.

To rinse the sand for the pool, all you need to do is rearrange the hoses. In this case, water from the pump begins to flow to the outlet of the filter, and contaminants are removed through the inlet.

The master making a filter with a barrel should not forget to check the reliability of the lid. If it turns out to be weak, then it will probably break under the pressure. Options for getting out of this situation: try to modernize the mount, or rearrange the pump hoses so that the pumping mechanism does not pump, but only sucks liquid out of the barrel.

Advantages and disadvantages of a DIY pool pump with a sand filter

There are indeed many advantages to such filtration units. Among the advantages of sand devices, one cannot fail to note:

AMETHYST - 02 M up to 2 cubic meters/day.

Aeration unit AS-1054 VO-90

Main table dispenser AquaPro 919H/RO (hot and cold water)

- simplicity of design and operation;

- ability to retain organic and mineral contaminants well;

- the ability to assemble a device from scrap materials.

The disadvantages include:

- effective against contaminants larger than 20 microns;

- impressive weight and dimensions of the system;

- difficulties during transportation.

Ratings of the best models

To obtain a high degree of purification of pool water, when choosing a filter unit, it is recommended to pay attention to the products of companies that occupy a leading position in the market. Among the models that make up the top list of pool filters, there are models of different volume and design

But to evaluate quality and performance, we selected models that have been at the top of consumer preference lists for several seasons.

Krystal Clear Intex 26644

A model of a popular brand of a manufacturer of household frame pools. The advantage of this model is its high performance in a small size. The declared productivity of 4.5 m3 is quite enough to clean pools with a volume of up to 25 m3. Connection to a standard pool is carried out using proprietary 38 mm hoses. The model has the ability to work in one of 6 modes. For ease of use, the model has a timer and pressure gauge. Krystal Clear Intex 26644 can be filled with both quartz and glass sand with a fraction of 0.4-0.8 mm. For a standard load you need 12 kg of regular sand, for glass - 8 kg.

The manufacturer's instructions say that one refill is enough for 3-5 years of operation.

The design is made on a platform. The body is made of impact-resistant polyethylene. The installation is compact in size and conveniently connected to the standard connectors of Intex pools. The instructions, in addition to the description, also have a disk with a film - instructions for connecting and servicing the installation.

Bestway 58495

The most compact pool filter model. The productivity is 3.4 m3 of water per hour. A 6-position valve is built into the polypropylene tank. The timer ensures automatic switching on and off of the unit. The built-in pressure gauge allows you to control the pressure inside the container.

A special feature of the model is the presence of a built-in ChemConnect dispenser. The device allows you to automatically add disinfecting chemicals to filtered water. The design includes an additional filter to capture undissolved particles. This function ensures long-term protection of the pump from damage.

Connections for connecting 3.8 cm hoses make the filter universal for connection to most popular models of frame pools. The volume of sand for filling into the filter housing is 9 kg.

Aquaviva FSF350

One of the largest filters for home pools. To load you will need 20 kg of quartz sand with a grain size of 0.5-1 mm. The tank of the filter unit is made of fiberglass. The housing material is not afraid of ultraviolet radiation; it can be installed outdoors.

The system has standard connection types using 50 mm hoses. The productivity is 4.3 m3 of water per hour. The housing can withstand pressure up to 2.5 bar.

Compared to other models, Aquaviva FSF350 operates at a water temperature of +43 degrees.

The system has a modular design. The filter housing and pump are installed on a common platform. The manufacturer recommends using the unit for pools with a volume of 15-18 m3.

Hayward powerline Top

This is the most famous and high-quality filter for home pools. This model provides water filtration with a capacity of 5 to 14 m3 per hour. This variation in performance is due to the fact that the pump for this filter is selected depending on the volume of the pool. The recommended bowl volume for the Hayward powerline Top is 25 m3. The design is equipped with a standard 6 position valve and pressure gauge. The body is made of impact-resistant polypropylene and can withstand a pressure of 2 bar.

To operate the filter, you will need 25 kg of quartz sand with a fraction of 0.4-0.8 kg. All Hayward powerline Top models are connected using 38 mm hoses.

Sand filter for the pool: instructions for use

Anyone who wants to organize their own hydraulic structure for swimming will have to think in advance about methods of maintaining it. Purification of the liquid must occur constantly. As a last resort, short-term interruptions (switching off) of purification devices are allowed if there is, in principle, no even minor contamination in the H2O, which does not happen often. You can turn off filtering devices no more than 2 times a day for 5-6 hours maximum.

Washing the sand base

The frequency of sand washing directly depends on the degree of its contamination, the intensity of use of the artificial reservoir and the volume of chemicals used. According to the recommendations, the sand mass should be washed at least once every 7-10 days. In this case, with regard to the pressure type design, pressure will be of great importance. Within normal limits it is 0.8 bar. If the indicator rises to 1-1.3, cleaning is required.

Replacing material

Over time, the filter part of the device becomes so clogged that it simply cannot be washed. All that remains is to throw away such sand and replace it with new one. If you purchased a quartz mixture as a filler, you won’t have to think about the need to purchase the next batch for 3 years or even more.

Features of use

The process of operating a cleaning device involves following a number of mandatory requirements:

- when switching the unit to another operating mode, be sure to turn off the pumping system;

- the sand layer is removed from the walls of the artificial reservoir by at least 1 m;

- for uninterrupted operation of the pump, it is provided with a constant flow of air;

- Any operations with the filtration device are performed in the off state.

Exploitation

If you create a pool filter circuit with your own hands, then all the difficulties associated with the work lie in how to place the water intake hose. It is usually recommended to use a float, which would allow the liquid to be captured from the surface. They also create a large pocket to make it easier to collect water.

The second hose, through which the liquid flows back, can be lowered into the pool. Then just turn on the pump and the process will start. However, for maximum efficiency, it is recommended to place both hoses as far apart as possible.

Device power calculation

The most efficient and productive devices are filters that operate on the pump principle (for more information about pool pumps, see here).

This can significantly speed up the flow of water. For example, water can be passed through a filtration unit several times a day

It is important to ensure that the system is capable of handling the specified amount of water

The formula used to calculate filter performance is:

Here V denotes the volume of the pool. To determine the volume, multiply the length, width and depth of the structure. So, if the pool has dimensions 4X6X2, then its volume will be 48 tons. If we talk about the filter productivity, it will be 12 m3/hour.

If the filter power is insufficient, the filter efficiency will decrease. The water will not be purified properly and the filter will become clogged faster. Therefore, be very careful when making your choice.

Installation and Maintenance

To install the system, you will need to complete the following steps:

- Selecting a site for installation located next to the surface water intake and outlet. The filter should be positioned horizontally on a level area.

- Remove the clamping ring using gentle movements.

- A six-way valve is screwed onto the pipe. They fix it.

- Install the pump next to the filter. Fixed with rod clamps.

- Fill the pool to the middle of the skimmer.

- Remove air from the hose by slightly opening the coarse cleaning cap. Waiting for the water to come out.

- Turn on the backwash pump.

- Switch to filtering mode, which should work daily for at least 3 hours.

The system should only work in water; if it is missing, the device will break.

After purchasing a sand filter, it is important to follow the maintenance rules:

- work is performed only in water;

- The sand composition needs to be cleaned 3 times a year (if the pool is installed temporarily, cleaning is carried out once per season);

- some devices are equipped with automatic cleaning, then there is no need to remove plaque yourself;

- when the valve is switched to a new mode, the pump is turned off;

- In order for water to be pumped correctly, the system requires access to air;

- if the pressure is increased, switching the valve is prohibited;

- periodic connection of reverse water flow.

With proper use, the device will work for 3-6 years.

Step-by-step manufacturing guide

The general design of a sand filter implies the presence of:

- Containers.

- Pressure gauge.

- Valve holes.

- Filtrate in the form of quartz sand.

- A coarse filter element to retain grains of sand so that they do not fall into the water.

- Pump.

Water from the pool is sent through the intake pipe to the filtration unit. Using a pump, it passes under pressure through a layer of sand that traps various pollutants. Then it is poured back into the bowl in a cleaned form through the nozzles.

You can make a sand filter from different containers and materials:

- aluminum flask;

- expansion tank;

- plastic barrel;

- plastic food container or bucket with a lid.

From a flask

To work you will need:

- aluminum flask with a capacity of 36 l;

- quartz sand (granules from 0.8 to 1.2 mm);

- stainless or plastic mesh with a mesh size of up to 0.7 (to keep sand out);

- welding machine;

- pipes and fittings (diameter 40 mm);

- ball valves of suitable diameter.

Procedure:

- Make a hole in the lid of the flask with a diameter of 40 mm.

- Cut the pipe using a welding machine.

- Treat with sealing compound.

- Make the same hole in the bottom of the flask and insert a fitting for water supply.

- The lid should be secured so that it does not allow water to pass under pressure.

- Connect ball valves to the fittings - they help change the direction of water for washing sand.

The video will show you how to make a sand filter from an aluminum flask:

From the expansion tank

You will need:

- membrane type expansion tank;

- paint that protects against corrosion;

- fittings;

- sealing compound;

- coarse filter (store-bought cartridge or homemade from a cut-off bottle);

- soldering iron;

- pieces of plastic pipe 50-80 cm long;

- mesh: the cell size is smaller than the sand fraction.

Procedure:

- Remove the expansion tank housing from the membrane.

- Paint the inside of the tank and wait until it dries.

- Holes are made in the walls of the housing or on the lid, and fittings are cut into them.

- The connection points are sealed.

- A coarse filter is attached to the supply fitting (it will protect against the infiltration of large contaminants).

- If you don’t have a ready-made cartridge, you can make a filter from the cut off neck of a plastic bottle, make holes in it and cover it with nylon tights.

- Prepare a water intake hole - it will be a perforated container with a mesh installed.

- Connect to the pumping unit.

Sand filter from the expansion tank, video instructions:

From a plastic barrel

You will need the following materials:

- plastic barrel;

- coarse quartz sand;

- pump with valve;

- flexible hoses;

- 2 plastic pipes;

- soldering iron;

- sealant;

- mesh with fine cells.

Procedure:

- You can use a soldering iron to make two holes in the tank corresponding to the diameter of the pipes.

- Seal the pipes inserted into the holes with sealant.

- Make a water intake from a plastic bowl, make holes in it smaller than the sand fraction.

- Wrap the bowl in several layers of nylon or gauze.

- Attach the hose to the water intake using sealant.

- Install a mesh on the inside of the inlet hole - it will break the stream of water.

- Attach the hoses using hot glue.

- Place the mesh on the injection to break up the water stream and distribute the water evenly onto the sand.

From a plastic container

To make it you will need:

- food box made of durable plastic (can be replaced with a plastic bucket with a lid);

- polypropylene tubes diameter 30 mm;

- soldering iron for plastic;

- quartz sand;

- neck of a plastic bottle with small holes;

- nylon stocking.

Procedure:

Two 30 mm holes are made in the lid of the plastic container (in the top and side). Two pipes 15 and 20 cm long are cut. Using a soldering iron, the pipes are fixed in the corresponding holes. It is important to securely secure the pipes in the container lid. Install a coarse filter (from a plastic bottle) at the bottom of the container. Fill the box 2/3 full with quartz sand. Close the lid. Connect to the pump.

Video with a visual example of production

- Author: Regina

Rate this article:

- 5

- 4

- 3

- 2

- 1

(12 votes, average: 3.3 out of 5)

Share with your friends!

How to choose the right pool filter: a comparative review of 3 filter devices

Which filter and pump to choose for the pool

Pros and cons of a homemade filter

The advantages of a self-made filter pump include:

- saving money: a homemade pump is cheaper than a factory device;

- solving the issue of frequent water changes;

- availability of repairs and replacement of components;

- ease of maintenance;

- reducing the cost of chemicals and cleaning products for the pool bowl.

Disadvantages of a homemade device:

- expenditure of physical effort and time;

- large dimensions compared to the finished analogue;

- lack of indicators indicating the need to wash the filters - the degree of clogging will have to be monitored independently.