Snow removal ordinary a shovel is very heavy labor, because it is necessary to make great efforts to lift the snow and throw it to the side.

The use of mechanical snow shovels (also known as miracle shovels, super shovels) seriously reduces the complexity of snow removal, since it is enough to move the tool forward, and the remove the snow to the side of the road on its own .

In most cases, mechanical snow shovels mean electric shovels (electric shovels), that is, small electric snow blowers.

What is a mechanical snow shovel?

There is no clear standard to separate mechanical shovels from snow blowers.

In industry , a mechanical shovel refers to any device that transfers bulk loads, including soil, from one place to another.

Therefore, we propose to consider any tools and mechanisms that meet the following criteria :

- have a mass of up to 15 kilograms ;

- their movement occurs due to muscular force , and a mechanism is responsible for removing snow;

- Suitable for cleaning small areas, such as the front yard or garage driveway;

- do not require training or education for work

- their cost does not exceed 10 thousand rubles .

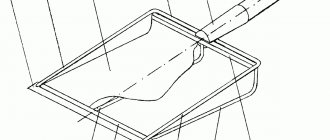

Bucket and skis

The helical blades of the snow clearing tool are surrounded by a special gripping bucket. The height and width of the layer that will be removed in one pass depends on its size. The larger the dimensions of this element, the more powerful and productive the device itself. If the bucket increases, then the thickness of the walls must also increase so that there is no deformation during operation.

In rotary designs, the bucket is mounted on special skis or guide skids, which are located on the sides. By changing their height, it becomes possible to regulate the distance from the grip to the ground, and therefore the thickness of the snow. It is advisable to install the skis so that the screws are 10 mm above the highest obstacle on the site.

To facilitate the removal of dense snow, a special trimming knife is attached to the bottom of the bucket. This is a sharp steel plate. The knife and skis do not last very long. They need to be changed periodically. To increase their service life, these elements are usually made double-sided so that they can be turned over when worn.

Types of mechanical shovels

two types of fall under the criteria described in the previous section :

- auger shovels (manual);

- electroshovels.

Auger

An auger shovel is a successful combination of a regular snow shovel and a two- or three-turn auger .

The principle of operation of this device is simple - when the shovel is pushed forward, the ribs of the auger touch the ground and begin to rotate.

At the same time, a rotating auger squeezes the snow onto the side of the road.

Such a device is not capable of throwing snow far , so to clear an area whose width is greater than the width of a shovel, you will have to spend a lot of effort .

After all, the auger squeezes out snow at a distance of 5–30 centimeters from the shovel (depending on the speed of pushing the device), which means that as the shovel moves towards the thrown snow, the thickness of the snow cover will become greater and greater .

The use of an auger shovel is limited by the physical capabilities of the person using it. In addition, an auger shovel is not well suited for removing compacted snow because it is difficult to crumble it into pieces that the auger can move.

Electric shovel

The desire to reduce labor costs when clearing snow led to the advent of electric shovels.

These tools are designed as simply as possible, so they only work in one mode .

An electric motor drives auger through a gearbox , which accelerates the snow.

From the auger, the snow enters a rotating nozzle , through which it flies out in the desired direction.

The working width of these devices is 20-30 centimeters , because it is limited by the engine power.

The more powerful the electric motor, the greater the amount of snow it can accelerate to the required speeds in a certain time period. An increase in the power of an electric motor is always associated with an increase in its mass ; therefore, in such devices, electric motors with a power of more than 2 kilowatts (usually from 700 watts to 1.2 kilowatts) are not used.

However, there are models of electric snow shovels with a working width of up to 50 centimeters , the power of their motors is close to 2 kilowatts, and their weight exceeds 10 kilograms.

Devices of such low power are used for cleaning small areas . After all, this snow blower performs the same functions as an auger shovel, only with less effort from the person using it.

Unlike a regular shovel, an electric shovel cannot remove deep or packed snow because it cannot dig to different depths or remove layers of snow.

An attempt to remove snow cover more than 20-25 centimeters (depending on the model) will lead to the fact that the device will not be able to throw away the snow, as it will bounce off the upper layers and fly away in all directions. In addition, a unit of this type will quickly get stuck , because the snow located on top will impede its movement.

Removing compacted snow with an electric shovel is not possible because to reduce weight they use a plastic auger that cannot withstand heavy loads. Also, this unit is not suitable for cleaning wet snow, firstly, wet snow clogs the gutter or is thrown out at a distance of less than a meter, and secondly, moisture can get into the contact of the extension cord socket and the plug of the device itself and cause a short circuit.

Read more about this problem in the article (Safety precautions when working with snow blowers).

Electric snow shovels are used only for clearing snow from flat surfaces , such as:

- asphalt;

- concrete;

- tile.

Attempting to remove snow from crushed stone or compacted soil will cause the auger to quickly break down .

After all, a plastic auger cannot withstand collisions with:

- earth,

- stones.

Some models are equipped with small wheels , which makes snow removal much easier , although it increases the weight of the unit.

Main types of devices

Snow removal products with an auger design can be manual or mechanical. These devices are also divided into self-propelled and non-self-propelled types. Shovels are manufactured in the form of designs with one or two stages.

To operate a hand-held device, you must apply force yourself. During pushing, the auger begins to rotate, due to which the snowballs are destroyed and removed to the side.

In mechanical models, a fuel or electric motor is installed, which is connected as additional equipment. If you connect the auger-shovel to the walk-behind tractor, it will be able to throw snow over a distance of 10-15 m.

Also, mechanical models can be supplemented with a fan , with the help of which the ejection is carried out. Thanks to the retraction sleeve, you can adjust any angle. The rotation speed of the ventilation blades is affected by the power of the connected motor.

Such a snow removal mechanism can be equipped with skis so that a person can move it around the site without much effort. These models are called non-self-propelled.

The single-stage shovel type has only one auger. There are knives arranged in a spiral on it. During rotation, snow is captured, which is then crushed and removed towards the blades. The last element of the mechanism pushes the snow through the discharge sleeve.

Two-stage designs have the same device. But in this case, the snow is first directed into the rotor to be rejected. After processing, it is discarded through a discharge hose.

How to choose a mechanical snow blower

To choose mechanical shovel, you need to answer several questions:

- what kind of snow will have to be removed;

- what area needs to be cleaned;

- where and how to store a mechanical shovel;

- an extension cord from the house to the cleaning site ;

- who will work with a mechanical shovel;

- who will service the mechanical shovel.

The electric shovel is suitable for clearing fresh snow up to 25 centimeters . An auger shovel is used to remove fresh and compacted snow up to 15 centimeters . If more , you will have to use either regular shovel or more powerful devices.

Mechanical snow blowers are used in areas up to 50 square meters, such as:

- platform in front of the door;

- path to the garage or gate;

- front yard;

- parking near the garage;

- small children's playground;

- local area.

Clearing larger areas is complicated by the fact that you will have to repeatedly shift the already removed snow, because an auger shovel throws it only 15–20 centimeters , and an electric shovel 3–5 meters . In addition, the electric unit cannot be used longer than 20–30 minutes , after which it requires at least half an hour of rest so that the motor has time to cool down.

Cordless snow blowers are too heavy and do not fit the definition of a mechanical shovel, so we dedicated this article to them.

To operate an electrical device, you must run an extension cord .

Particular attention must be paid to the outer coating of the extension cord - you cannot use those that are afraid of snow and water or crack in the cold, that is, from:

- plastic,

- fabrics.

Therefore, coated with:

- rubber,

- silicone.

If it is not possible to extend a normal extension cord that is not afraid of wet snow and frost, then choose other types of snow blowers.

If you entrust snow removal to children, auger for them , because it is much less dangerous , and a rapidly rotating auger can seriously injure a child.

Self-production

Factory-made auger shovels are quite expensive, so to save money you can make the device yourself. If you use an electric motor, the device will depend on the power source, and this is quite inconvenient. It is best to use a gasoline engine.

The procedure for making a shovel with your own hands:

- For the auger you need to take a pipe with a cross-section of 20 mm. Trunnions are welded along the edges and bearings are put on. If you decide to use a belt drive, then you need to attach a pulley to the axle. In the case of a chain drive, it is necessary to use a bicycle sprocket. To obtain blades, you should weld several sheet steel plates (at least 2 mm thick) in the center of the pipe. Rings for disc blades can be cut from an old car tire.

- It is advisable to weld the frame from corners, but bolted connections can also be used. You must remember to provide a place to install the engine.

- Now you need to take a sheet of steel 50 cm wide and bend a ladle, the diameter of which will be 30 cm. For knives, 1.5 cm should be left on each side, that is, their diameter will be 28 cm. Thick sheets of plywood are attached to the sides, in which you need to cut holes in the center. The hub will be fastened through them. A sleeve for throwing snow is installed in the middle of the body. It is necessary to make a hole with a diameter of 16 cm.

- A sprocket is installed on the engine.

- The shaft is inserted into the hubs, after which the bucket is mounted on the frame.

- The engine is secured.

- For the chassis you can use skis or wheels.

- The control handle is being installed. It can be made from a curved pipe in the shape of the letter P.

- Now you can carry out the first launch.

An auger shovel is a very convenient tool for removing snow. The main thing is to make a responsible choice so as not to overpay for unnecessary features or break the device when used in harsh conditions. If you don’t want to spend money, you can assemble the unit yourself.

Cost and best models

Stores offer only two models of auger shovels, but the number of models of electric snow shovels is in the hundreds . We have prepared two tables that describe in detail the most important characteristics of both devices. In addition, you can use various price comparison , such as:

- Yandex Market;

- Tovary@Mail.ru;

- Wikimart.

Screw

| Name | Working width | Grip height | Weight | Price | Snow throw direction |

| Forte QI-JY 50 | 57 cm | 15 cm | 3.82 kg | 2–3 thousand rubles | right |

| Patriot (Patriot) Arctic | 60 cm | 12 cm | 3.3 kg | 2–3 thousand rubles | right |

Electric shovels

| Model | Power, kWt | Width and height of grip, cm | Screw material | Selecting the direction for throwing snow | Snow throw range, meters | Weight, kg | The presence of support wheels at the rear | Average price, thousand rubles |

| Daewoo Power Products DAST 3000E | 3 | 51x33 | rubber | mechanical | 12 | 16,8 | Yes | |

| Huter SGC 2000E | 2 | 46x20 | rubber-plastic | mechanical | 3 | 10,6 | Yes | |

| AL-KO SnowLine 46E | 2 | 46x30 | rubber | mechanical | 10 | 15 | Yes | |

| Zitrek ST1300 | 1,3 | 28x15 | rubberized plastic | No | 6 | 5,5 | No | 3,5 |

| Zitrek ST2000 | 2 | 30x15 | plastic | No | 6 | 6 | No | 4,5 |

| Denzel EST-51Li rechargeable | not specified | 51x21 | rubberized plastic | mechanical | 4 | 20 | There is | |

| Hyundai S 500 | 2 | 46x33 | rubber | mechanical | 6 | 14 | Yes | 11,5 |

| Hyundai S 400 | 2 | 45x25 | rubber | mechanical | 10 | 11 | Yes | |

| Sibrtech ESB-46LI battery | 1,3 | 46x31 | rubber | mechanical | 6 | 16 | Yes | 16 |

| Daewoo Power Products DAST 2500E | 2,5 | 42x25 | rubber | mechanical | 10 | 15 | Yes | |

| Greenworks GD40SB rechargeable | not specified | 50.8x15 | rubber-plastic | mechanical | 6 | 15,5 | Yes | |

| Sibrtech ESB-2000 | 2 | 46x31 | rubber | mechanical | 9 | 15 | Yes | 9,5 |

| CHAMPION STE1650 | 1,6 | 50x33 | rubber | mechanical | 7 | 16 | Yes | 8,5 |

| Huter SGC 1000E | 1,2 | 28x15 | rubber-plastic | No | 3 | 6,5 | No | |

| Carver STE 1333 | 1,3 | 33x15 | plastic | No | 6 | 6,3 | No |

Auger miracle shovel FORTE QI-JY-50

The domestic market is flooded with cheap Chinese and expensive European goods. Scrapers with an auger from the first manufacturers are unreliable, and not everyone can afford them from the second ones. Occasionally, shovels of domestic brands appear, but they are less in demand. An example is the FORTE QI-JY-50 model. The product is more reminiscent of a traditional scraper with a height-adjustable U-shaped handle. The model with an auger is lightweight, compact, and easy to transport. This is where the main advantages of the shovel end.

A scraper can be used to clear a small area with a thin layer of snow. Even if the mass is loose, most of it remains in the bucket. Snow can only be removed by turning the scraper over, and this is an additional load on the spine. The auger rotates from the pushing movements of the operator, subject to the repulsion of the knife blades on a hard surface. On uneven terrain, the shovel screw does not always touch the frozen ground. When the auger stops rotating, the snow does not grind and sticks inside the bucket. However, it is still easier to work with a manual snow blower with an auger than with a shovel with a wooden handle.

The FORTE snow blower bucket is made of durable plastic. The blade is capable of capturing a strip of snow 60 cm wide in one pass.

Advice! Model QI-JY-50 is convenient for home use. A manual snow blower with an auger is used to clear snow from paths and an area near the entrance to a house or yard.

User reviews

Store employees interested in increasing sales advertise the most expensive models, but do not reveal their real capabilities. Often because they themselves don’t know. Therefore, the only way to find out the real capabilities of such devices is to look through the numerous forums where they discuss the experience of using mechanical shovels.

Here are some links to such forums:

- Forumhouse is one of the most popular forums for those interested in the construction, renovation of houses, their maintenance and country life.

- Master City is another popular forum where builders, renovation specialists and those who live in their homes communicate.

- Drom is an active forum where a variety of issues are discussed - from car repair to house construction.

- Auto is a forum for those who like to do things with their own hands.

- Your Garden is a forum for those who independently care for their home and garden.

Most reviews agree that mechanical shovels are only good for fresh , thin snow. If you have to remove compacted, wet or thick snow , then it is advisable to buy a more powerful unit or use a regular shovel. Therefore, mechanical shovels are only good for cleaning small areas, such as the area in front of the house or the entrance to the garage.

How to choose a snow shovel?

A winter tool is selected based on individual preferences, however, there are mandatory conditions that it must meet:

Strength. A snow shovel should not break on the first day of use. This is especially true for plastic products, which, despite all their positive aspects, are fragile. It is necessary to check the elasticity of the bucket by placing it on the floor and leaning lightly on the handle. Material that is too soft will not cope with compressed snowdrifts, and plastic that is too hard will simply break under pushing load or burst from frost. Therefore, the plastic must be frost-resistant. It is obligatory to have galvanized edging at the end and stiffening ribs. Perhaps moisture resistance can also be included here. Wooden options do not have this. The plywood surface will last long enough only if all the stuck snow is removed from it with a broom or brush after work.

- Lightness is perhaps the most important criterion. A good snow shovel weighs no more than 2 kg. Otherwise, it will be extremely difficult to unlock the potential of a large scoop, due to rapid fatigue when working with a heavy tool.

- Ease of use. The determining factor here is the length of the cutting, which is selected individually. When working, a holder that is too short will put a serious strain on your back, which will be constantly bent. Too long will create inconvenience. The comfort of using a winter tool is enhanced by a plastic handle at the end of the handle, made in the shape of a T or V.

You should also focus on the expected range of tasks.

For example, you should clean a metal tile roof with a plastic tool without a metal edging, while breaking up frozen snowdrifts - preferably with a steel shovel.

Where can I buy

There are two options to buy mechanical shovels:

- buy them in the store;

- order online.

Purchasing a device in a real store or online store office is preferable, because in this case you can make sure that you are purchasing exactly the unit that you chose or ordered. In addition, the store will check it and, if something does not work correctly, they will provide another snow blower of the same model or return the money.

If you buy a mechanical shovel in an online store and cannot visit the office yourself and pick up the goods, then it will be delivered to you by mail or transport company. In this case, you lose the benefits described above.

If you receive the wrong device that you ordered, or it turns out to be faulty, then you will have to at your own expense and wait for one of two things:

- reimbursement of all your costs (cost of the device plus delivery price);

- delivery of a similar product and refund of the shipping costs to you.

Most likely, the money for sending the mechanical shovel to the seller will be returned , but this will not happen soon. If you don’t like the color or some other parameter, then you will not be able to return the shipping costs.

Therefore, it is preferable to pick up the goods from a store or office yourself, in this case you will not have to spend money on shipping. After all, if you don’t like something, then you have the right to immediately demand a replacement, and store employees have no right to refuse you.

When choosing via the Internet, it is convenient to compare models and see the characteristics immediately along with prices. One of the most convenient options is Yandex.Market.

This is what the interface for choosing an electric shovel looks like in one of the online stores:

Augers and rotor

The main structural element of the snow removal device is shaped like a screw. The auger is very similar to a regular meat grinder. The edge shape varies. It can be smooth or jagged. Shovels with a smooth edge are suitable for clearing fresh, loose and wet snow. In different models, the relief edge has a different shape and number of working teeth. Such augers can clear the area of absolutely any snow.

Manual models use rubber or composite (rubber and plastic) augers. They can be reinforced with steel or be completely metal. Reinforced elements can often withstand a collision with an obstacle, such as a stone or stump. This manufacturing approach is especially relevant in single-stage snow blowers, where very fast rotation is necessary to throw the required distance.

In two-stage products, the rotor throws snow away. This element is made in the form of an impeller, which often has 4-6 blades. The impeller is made of metal or plastic. It all depends on the purpose for which the tool is purchased.

When the auger or impeller jams, other components of the mechanism may also break. If the electric motor fails, you will have to repair or replace it, and this costs quite a lot. To prevent such consequences, the augers are installed on safety bolts. They are specially made so that they will break off under heavy load. Most often, this allows you to save the engine and gearbox.

Warranty repair

Regardless of how you purchase a mechanical shovel, you still receive a warranty and can have repaired free of charge if it breaks.

Delivering a broken unit to the store’s office will save you from having to independently deliver it to the seller or to the workshop, the address of which is indicated in the documentation for the snow blower. Then the store or workshop employees will conduct an examination, which will either recognize the case as covered by warranty , and then the unit will be repaired for free, or not.

If the case is deemed non-warranty , then you will have to pay for the repairs yourself or contact the consumer protection department with a request for an independent examination. If an independent examination recognizes the case as covered by warranty, then you will either have the device repaired free of charge, or you will have to go to court with a statement of claim.

Warranty service for a device received through mail or a transport company can be very expensive due to the need to independently pay for shipping the unit to the repair site.

Approximate prices

- Wooden shovel made of plywood - from 150 rubles.

- Snow removal tool with a steel bucket and wooden handle – from 300 rubles.

- Aluminum spades sell for 600-700 rubles.

- Domestic ordinary plastic shovels cost no more than 240–300 rubles, imported ones - from 900 rubles. Original models can cost up to 2 thousand rubles.

- A simple scraper (shovel-scraper) with a plastic bucket – 1-2 thousand rubles.

- Mechanical snow blower with a steel auger retail – from 1 thousand rubles. Electrified rotary tools – from 6 thousand rubles.

- Two-wheeled scraper with a steel bucket from 4 thousand rubles. Four-wheeled models of manual scrapers - from 6 thousand rubles.

Snow shovel

Service maintenance

Like any other complex mechanism, this tool requires regular maintenance , which includes:

- snow removal

- changing the oil in the gearbox (for some models);

- checking the condition of bearings ;

- checking the condition of the auger and replacing it if necessary;

- checking all switches and wires .

It is advisable to carry out servicing in specialized workshops to avoid loss of warranty (if this is specified in the sales contract).

However, many models can be serviced independently , so the operating instructions describe in detail all the necessary actions and their order.

Compliance with these recommendations will protect the unit from breakdown and extend its service life.

The video shows the operation of the Patriot 2200 2KW electric snow shovel:

Pros and cons of auger shovels

Scrapers with an auger, when used correctly, have more advantages:

- cleaning of large areas is accelerated;

- a person makes less effort, does not spend additional strength throwing snow like a regular shovel without an auger;

- the mobility of a hand tool with an auger allows you to take it with you on the road or transport it by car;

- The steel auger is almost impossible to break, which increases the service life of the entire tool.

The disadvantage of a shovel is the high cost of a factory-made product. However, here too the craftsmen found a way out. A scraper with a screw knife is made independently from sheet steel.

Let's sum it up

Mechanical shovels are a good alternative to conventional shovels. After all, snow removal is much easier with their help. However, mechanical shovels are only suitable for clearing fresh snow with a cover thickness of up to 10–25 centimeters , depending on the model. The most convenient to use are those devices that are equipped with wheels - they are easier to move along a cleaned surface.

Mechanical shovels are well suited for cleaning small areas, the area of which does not exceed 50-150 square meters (depending on the model). Mechanical shovels:

- weigh much less than full-size snow blowers;

- do not take up much space;

- are inexpensive;

- Ideal for cleaning small surrounding areas .

Therefore, they are mainly in demand in private homes, but they will also find application in organizations with a small territory.

How to choose and buy a manual snow blower: operating features of the main elements

Purchasing a manual snow blower means using it exclusively at home.

However, even if used at home, there are quite a lot of requirements for this device. And the material used to make the impeller is one of the main ones. Undoubtedly, metal parts have a serious advantage over plastic ones: they last longer and are able to withstand significant loads. But at the same time, the cost of such devices is noticeably more expensive. Another important point is the choice of motor. It is obvious that the motor is the main driving force of any such mechanism, and the results of your work, as well as the amount of effort expended, directly depend on its quality. The two biggest challenges a snow blower motor has to deal with are sub-zero temperatures and solid objects that can get caught inside. And the failure of one component leads to a malfunction of the entire system.

Making a snow blower with your own hands is not difficult, and as a result you can get a good device for relatively little money

To prevent the occurrence of malfunctions, use the following scheme for connecting the elements: using a pin or a cut bolt, which acts as a fuse, the auger is fixed to the drive shaft. This system allows the bolt or pin to break instantly if the auger becomes blocked. After all, it is much easier to replace such a small component than to engage in complex and expensive engine repairs.

Depending on the type, motors for snow blowers can be divided into two classes: electric and two-stroke internal combustion engines. Using the second option is more profitable and rational, however, electric motors also have a number of advantages: they are cheaper, light weight, do not pollute the atmosphere, are easier to maintain and have a significantly lower vibration level.

DIY shovel for walk-behind tractor

For large areas or when living in an area with snowy winters, it is preferable to use a snow shovel on wheels. The use of such devices greatly simplifies the cleaning process. You can make the device from a walk-behind tractor and available tools.

Any walk-behind tractor with a power of more than 4 liters is suitable for installing a snow blade. With. The efficiency of the unit depends on its weight, so it is necessary to use a device weighing at least 50 kg. A blade shovel is attached to the walk-behind tractor, which will be used for cleaning.

Drawing of a shovel blade for a walk-behind tractor:

It can be made from different materials. It can be:

- Old gas cylinder. Its walls are strong, so they can easily cope with high loads. A unit with such a blade can not only remove loose snow. It can be used to level roads and remove stones and rubble.

- Metal barrel. Since it consists of thin steel, the blade made from it is not very durable. But such a shovel is also effective for clearing fresh snow from an area.

- Metal strips. A blade for a walk-behind tractor can be made from a truck bumper or from corrugated steel. Such material is quite difficult to find.

To prevent the snow removal unit from getting stuck in deep snow due to its heaviness, tracks can be installed on its axle shaft.

When drawing up drawings for making a shovel for a walk-behind tractor with your own hands, it is necessary to correlate the volume of expected work with the power of the device. Due to overload, the machine will quickly break down.

When making a blade, it is necessary to take into account the following features:

- Strength. All parts of the snow blade and mechanisms should be designed to withstand maximum load and high impact.

- Dimensions. The optimal dimensions for a homemade shovel are considered to be 80-130 cm in width and no more than 50 cm in height.

- Lifting mechanism. It is advisable to provide lifting of the blade using levers or hydraulics. Thanks to this function, you can transport snow outside the territory.

- Depreciation. To protect the unit from impacts and prevent the bucket from breaking, you need to install a shock-absorbing strip. The best material for it is dense rubber.

When making a bucket from a barrel, you need to make markings. The bottom and sides are divided into three sectors measuring 120 degrees. A grinder is used for cutting. There is no need to remove the end parts - they provide rigidity.

If the material is not strong enough, you can join the two parts together. It is advisable to lubricate them with hot bitumen to prevent corrosion and increase the mass of the dump. The parts can be secured with bolts or rivets. The perimeter of the bucket is reinforced with a steel strip, the thickness of which must be at least 3 mm. It can be welded or secured with rivets.

A conveyor belt is placed in the lower section of the bucket. It should be removable - this will allow the blade to be used for bulk materials.

After this, the workpiece is cleaned of rust and treated with anti-corrosion agents. If desired, you can paint it.

If the blade is made from a gas cylinder, then it does not need to be further reinforced. Otherwise the principle of operation is similar.

In order to attach the bucket to the walk-behind tractor, you will need a profile pipe. It is welded to the bucket from the reverse side. You can increase the strength of welding using bolts. A metal semicircular blank 10 mm thick and up to 25 cm in diameter is welded to the pipe. Holes are made in it at a distance of 20 mm from each other. The holder is made of a pipe with a square cross-section, giving it the shape of the letter “g”. The long part of the holder is attached to the bracket of the walk-behind tractor, and the other side is attached to a metal semicircle with holes.

Option for a snow shovel-blade for a walk-behind tractor in the video:

What to make a shovel from?

Before making a snow shovel, you should decide on the material to work with.

Most often, such devices are created from:

- Plastic. Plastic products are characterized by lightness and convenience, so they are used very often. Making such a snow scraper with your own hands is quite easy. To do this, you can buy a ready-made scoop in the store and connect it to the cutting.

- Iron or zinc. The advantage of these materials is their strength. But metal products are heavy, which makes them difficult to use. In large areas it is inconvenient to use such devices.

- Aluminum. The aluminum snow shovel is durable and lightweight. Therefore, such products are very popular. They are also often made at home.

- Tree. This is a strong and durable material. If the manufacturing technology is followed, a wooden shovel will last a long time.