Types of blind areas

Before you properly make a blind area around the house with your own hands or order its construction, you need to decide on the type. There are three options for top coating:

- Hard coating. It is a monolithic tape made of concrete or asphalt concrete. In the first case, when creating a blind area with your own hands, they make formwork and carry out mandatory reinforcement, and in the second, neither formwork nor, accordingly, reinforcement is required, due to the resistance of asphalt concrete to bending loads.

Arrangement of the base and pouring of the blind area around the house is carried out using the same technology as for the paths, but taking into account the obligatory requirement for a slope from the base.

Protection from water occurs due to the water resistance of both types of concrete. Therefore, it is important that there are no cracks or tears in the coating on the surface. The second feature is that a gap is required between the blind area and the base to compensate for the thermal expansion of the monolithic coating.

- Semi-rigid coating. They are made from paving slabs, clinker bricks or paving stones. The design and installation method are carried out by analogy with sidewalks and platforms made of these materials with the obligatory creation of a waterproofing layer as part of the blind area:

- waterproof geomembrane, when laid on a dry sand-cement mixture;

- concrete monolithic base.

- Soft covering. The classic option is to arrange the top layer from a compacted layer of dense (waterproof) clay. Many people know how to make a blind area of this type: it used to be done around village houses, and even now this solution is periodically used as an “economy option” around small country houses, but with a top layer of decorative (colored) gravel.

To improve waterproofing, a waterproof film can be laid between clay and crushed stone. You need to understand that the blind area is not just decoration; you shouldn’t save much on it.

Now a new type of soft blind area around the house based on a profiled membrane is gaining popularity. The general procedure here is as follows:

- The membrane is laid in a trench with a depth of 25-30 cm.

- The bottom of the trench is compacted with a slope from the foundation.

- A layer of filtering geotextile is rolled out over the membrane, extending onto the base wall of the house.

- Then a drainage layer of crushed stone and sand is poured, and fertile soil is placed on top of it, which is sown with lawn grass or ornamental plants are planted.

This blind area is also called hidden. This is a beautiful solution, but with a significant drawback - it is not recommended to walk on soft surfaces. However, you can always additionally organize a path.

What is

A concrete blind area is an external structure with waterproofing, which is installed along the perimeter of the building and has a slight slope from the wall to the topography of the garden area. According to the requirements of the project, the structure is pressed tightly against the base of the house, but is made movable. In structure, it resembles a layer cake, which has the following components:

- Base layer (bedding). It is created from crushed stone or clay.

- Waterproofing layer.

- The top covering is concrete.

Work order

Work on the construction of the blind area should be carried out in the warm season. As an example, let's look at step-by-step instructions for making a blind area around a building with your own hands:

- Performing markings. Measure the calculated distance from the wall of the building. Hammer wooden pegs and stretch the rope over them.

- Excavation. The construction of an earthen trough for the future blind area is made with a depth of about 250 mm.

Plant processing. To do this, it is necessary to treat the visible part of the roots of plants, shrubs, and trees with a herbicide solution.

- Formwork assembly. Install a 25 mm thick unedged board along the outer edge of the blind area. Secure firmly with a peg and prop.

- The device of the bottom layer. A five-centimeter layer of clay is laid, then sand, spilled with water and compacted. Now lay a layer of crushed stone, fraction 15-20, and compact it thoroughly again.

- Laying of reinforcement. Place reinforcing mesh on the prepared cushion and securely fasten them together.

Installation of expansion joints at the junction of the building and the blind area. Make the joints 15 mm wide and fill them with a mixture of sand and fine gravel.

- Concrete works. Fill the formwork space with a liquid concrete mixture. Every 2500 mm, make expansion joints from wooden slats. Pre-treat the slats with an antiseptic.

Using the rule, level the concrete mixture evenly and give it the required slope. Cover the concrete surface with a wet cloth and leave for 28 days to achieve design strength.

- Decorative design. Now you can refine the concrete surface with natural stone or tiles.

You did it! In fact, there is nothing complicated. If you follow the recommendations of experts, then making the blind area yourself correctly will not be difficult. Costs include only the cost of materials.

Equipment and tools

In order to deepen the plane of the blind area into the ground, you need to dig a trench under it, the depth of a shovel bayonet. This means that for work you will need two types of shovels - a shovel and a bayonet. To assemble the formwork, you will need the necessary set of carpentry tools, a hammer and nails.

Working with the solution requires a concrete mixer, buckets or stretchers to carry the finished mixture. For tamping, you can get a vibrating plate so as not to do it manually. Trowels, rules and a level will be useful to level and make the blind area according to your mind.

Design features and requirements for the blind area

The design of the blind area includes 2 main layers. The first one is the underlying one. Its main function is to create a dense, reliable foundation for the overlying layer. The underlying layer can be made with or without a slope. To make this design ball, it is allowed to use crushed stone, gravel, and sand. The recommended thickness of the underlying layer is about 2 cm.

- Sometimes the soil around the building is additionally treated with special chemicals - herbicides. The use of these prevents the growth of plant and grass roots in the future, thereby minimizing the risk of compromising the integrity of the supporting structure of the house.

- The top layer is a coating that provides a decorative function and protects the foundation from water. Thickness – up to 100 mm. Asphalt, paving stones, concrete and other materials are used to make the top ball.

- In addition to the above, the blind area includes other important layers. The structural features of the structure can be seen in the following image.

In order for the blind area to fully cope with the previously mentioned tasks, in the process of its arrangement it is necessary to ensure that a number of important requirements are met.

- Firstly, the width of the blind area must exceed that of the roof overhang. When arranging a site on sandy soil, it is recommended to make its width 25-30 cm larger than the cornice (the total width should be more than 60 cm). In most cases, the total width of the blind area does not exceed 80 cm, but when working on heaving type soils, this figure increases to an average of 100 cm.

- Secondly, the blind area must be made with a slope in the direction of the site. The specific slope value is selected taking into account the characteristics of the finishing coating. For example, in the case of a concrete blind area, a 3-10 degree slope from the walls is made. The minimum acceptable slope, regardless of the material used, should be 1.5 degrees.

- Thirdly, the blind area must be continuous, encircling the entire perimeter of the building. It is strongly not recommended to make gaps - the overall quality of the design will significantly decrease.

Fourthly, the blind area cannot be connected to the foundation - these systems are characterized by different degrees of settlement. In view of this, a minimum 1-1.2 cm expansion joint must be maintained between the supporting structure and the surrounding surface.

It can be filled with bitumen, sealed with sealant, filled with geotextiles and similar materials, or filled with sand.

How to protect the blind area from destruction

Since concrete is used to construct a boundary strip around the perimeter of the foundation, it may be subject to damage and cracks. Most defects are a series of deep or superficial cracks, traces of crumbling and subsidence. Cases of tiles peeling off from the basement of the building cannot be ruled out.

Such phenomena are associated with the following factors:

- Failure to comply with installation rules. Often, builders ignore the importance of waterproofing, do not ensure optimal compaction and uniformity of backfill, do not comply with dimensional standards and make other primitive mistakes. Another problem arises when choosing the wrong recipe for a concrete mixture, when the composition contains an insufficient or excessive amount of binder additive. The first option threatens cracking of the surface, and the second - crumbling.

- The absence of an expansion joint that prevents damage to the supporting structure due to temperature changes or precipitation.

- Lack of reinforcement in the blind area. Some home craftsmen refuse to lay this layer, arguing that its presence is not specified in SNiP standards. However, the metal elements make the strip not only functional, but also durable.

To protect the blind area from any negative factors, it is important to monitor the width and density of filling expansion joints and restore them in time. Instead of wood, it is better to use 15 mm thick vinyl tapes. If the building stands on heaving soil, the blind area should not be connected to the basement part.

To increase the tightness of the concrete composition, it is treated with a deep penetration primer.

Requirement for the blind area

There are no requirements in any regulatory document that would link the size of the blind area with the roof overhang. Moreover, there are no requirements to exceed the width of the blind area by 20-30 cm in relation to the projection of the cornice extension. When building a blind area around a concrete house with your own hands, you do not need to rely on these numbers.

The regulations provide only two minimum width sizes. And they depend on the soil:

- on sandy ones - from 70 cm;

- on clayey soils – from 100 cm.

This is exactly what is stated in the manual on construction operational control schemes for supervisory services.

With unorganized drainage, the side roof overhangs of houses up to two floors should be less than 60 cm. If the house is on sandy soil, then the difference between the width of the blind area and the amount of roof overhang can be equal to 10 cm, and not contradict the requirements of the standards.

That is, it turns out that the parameter 20-30 cm is simply a statement of the real ratio of two sizes for most cases. But not for everyone.

If the soils are subsident, depending on their type, the standards impose other requirements for the width:

- Type I – more than 1.5 m;

- Type II – more than 2 m.

And in any case, the blind area should be 40 cm wider than the bosom of the pit.

The slope angle can be in the range of 1-10%, but in the case of subsidence soils the minimum angle is 3°, which in terms of 5.2%.

The elevation of the outer edge of the blind area above the site should be more than 5 cm.

Main stages of manufacturing

You should start making a blind area around the house as early as possible, preferably immediately after the construction of the building. It is better to do this simultaneously with cladding the walls and base.

Insulation of the blind area

Preparing the pit. Insulation

- After removing the soil to the required depth (average depth 30-40 cm, that is, the bayonet of a shovel), it is leveled and compacted. If it is too loose, you should make a backfill of sand with a slight slope from the building or secure the pit with carefully compacted clay

- For heaving soils, a layer of clay is laid at the bottom of the underlying layer, and then sand is poured in. On ordinary soils, only a layer of clay is enough

- Next, a layer of a mixture of sand and crushed stone is poured. It is carefully leveled and compacted

- A heat-insulating material that is not subject to rotting (foam plastic, expanded polystyrene) is laid on top or expanded clay is poured. So waterproofing will be applied further; there is no need to fix the thermal insulation

- It is better to use polypropylene film as a waterproofing layer. Polyethylene or roofing felt are less durable and will last less time. Rolled materials are overlapped on top of each other, extending 15 cm onto the foundation. The seams are additionally taped with construction tape. To prevent the film from leaving the walls, it is secured to them with mastic or wooden blocks.

Manufacturing of formwork

A monolithic concrete strip is more durable and will last longer. You can also use ready-made concrete slabs.

Formwork with expansion joints ready for concrete pouring

To make a concrete strip, formwork is prepared:

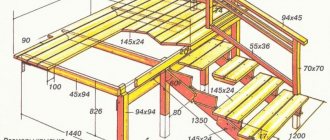

- Before you begin installing a concrete blind area, you should determine its thickness

- When calculating, it is assumed that reinforcement will be laid inside it, for which it is necessary to retreat 30 cm on both sides. Thus, the minimum thickness of the blind area will be 70 mm

- As reinforcement, use a metal mesh with cells of 100x100 mm or rods with wire binding. When using rods, the cell size is at least 50x50 cm. A strong metal frame is required to ensure that the concrete does not crack under severe temperature changes and under the influence of physical factors

- To make formwork, pegs are driven around the perimeter of the pit, to which boards mounted on the edge are screwed with self-tapping screws. They are connected using 40 cm wooden blocks and self-tapping screws

- In the corners and at joints it is necessary to further strengthen the formwork with stakes and metal corners

- impregnated with bitumen must be laid across the formwork They will act as expansion joints. The distance between the bars is 2.5-3 m. The structure, divided into squares, will not be afraid of soil movements. They are laid in such a way that the upper ribs are flush with the concrete surface. Its slope must also be taken into account. When pouring the solution, they will serve as beacons for leveling

- The formwork can also be made permanent . It is often used as borders dug into the ground. They also need to provide expansion joints. They are subsequently filled with sealant.

- When using drainage pipes to collect and drain water from the blind area, they are placed in the formwork

Expansion seam

Subsequently, such an expansion joint is filled with sand or sealed with sealant or covered with roofing felt.

Preparation of the solution

The strength and service life of a concrete blind area directly depends on the quality of the solution. It is advisable to use cement marked VRC - waterproof.

According to SNiP, the use of cement M200 and higher is allowed for the blind area. But, since its quality has not been up to par in recent years, it is better to play it safe and use material of the M300-400 grades. For pouring on difficult soils, it is better to purchase M400 cement. It is not afraid of moisture and tolerates sudden temperature changes.

Preparation of concrete solution

When calculating the amount of concrete, it is taken into account that about 350 kg of solution will be needed per cubic meter of the structure. Recommended pouring thickness is 10-15 cm.

Key points when making concrete:

- Crushed stone or rubble stone is used as a filler to relieve concrete stress. It is not advisable to use gravel. It is too smooth and does not adhere well to the solution.

- The proportions of the solution are selected depending on the brand of cement. For example, for M400 cement with the addition of crushed stone and sand, the proportions will be 1:3.2:1.6. Please note that the calculation is based on volume as an example, that is, in liters and not in kilograms. To calculate by weight, use the table (see photo)

- To avoid the formation of lumps, you must first mix the dry materials, and only then add water to the mixture

- After adding water, the solution should not stick to the shovel, but should not run off it either

- It must be kneaded at a temperature not lower than 5°C, so it is not worth working in cold weather for years. Otherwise, the quality of the concrete will not be up to par.

- Only clean sand is used, preferably river sand, without any admixture of clay or debris. To test, mix it with water. If the liquid becomes very cloudy, you should not use sand - it contains clay impurities

- To increase frost resistance and reduce water resistance, special additives can be added to the solution, for example, powdered “Betonoprav” or “Dehydrol”. For 200 kg of dry ingredients you will need 0.4 liters. The procedure for adding them can be clarified in the instructions.

- The solution should be used within an hour. After this time, it will set and will be unsuitable for work.

Solution proportion table

| Concrete grade | Mass composition (C:P:SH) kg | Volume composition for 10 l. cement (P:SH) l. | Concrete yield from 10 liters. cement, l. |

| M100 | 1:5,8:8,1 | 53:71 | 90 |

| M150 | 1:4,5:,6,6 | 40:58 | 73 |

| M200 | 1:3,5:5,6 | 32:49 | 62 |

| M250 | 1:2,6:4,5 | 24:39 | 50 |

| M300 | 1:2,4:4,3 | 22:37 | 47 |

| M350 | 1:1,6:3,2 | 14:28 | 36 |

| M400 | 1:1,4:2,9 | 12:25 | 32 |

Common mistakes when creating a blind area

Errors can happen at any stage. Therefore, it is very important to know how to properly fill the blind area around the house. But even with technology, you need to be careful.

For example, insufficiently compacted backfill soil leads to “unplanned” shrinkage and destruction of the integrity of the waterproofing layer or rigid covering. The same consequences occur if, due to the negligence of workers, construction waste gets into the backfill.

At the stage of compacting the bottom of the “trough”, it is necessary to maintain the level of the bottom of the pit and its slope. This is one of the important conditions for how to properly make a blind area around the house. Irregularities in the bottom lead to uneven thickness of the crushed stone layer and differences in its load-bearing properties in different areas, which can cause cracks in concrete.

And if the slope of the trench profile is incorrect, during the rainy season or melting snow, the perched water will literally flow down to the foundation from the moisture-saturated soil.

Another mistake is the lack of an expansion joint between the concrete blind area and the plinth. At high air temperatures, internal stress forces arise in the concrete near the wall, which lead to the appearance of cracks. The same thing happens if transverse expansion joints are not laid or cut in the reinforced concrete blind area.

When preparing concrete mortar, it is unacceptable to use sand containing clay and dirty water. This will deteriorate the quality of the concrete and reduce the service life of the blind area.

If a tap for irrigation is provided in the basement of a private house, then a separate gutter must be laid under it. It is needed to drain water beyond the blind area in case of leakage of shut-off valves or a leaky hose connection.

The maximum slope angle of the blind area is 10%. And with organized drainage of water from the roof, trays must be laid under drainpipes with a slope of more than 15%. This regulatory requirement is sometimes ignored.

The feasibility of pouring a concrete structure yourself

In fact, the installation of a blind area is a labor-intensive technological process, consisting of many important stages that require the performers to have construction experience, the necessary tools and devices.

It is impossible for one person to complete such work ; a team of at least 2 people will be required.

In addition, it is not recommended to independently perform blind areas for construction areas with difficult soils and houses with large external dimensions, having an area of more than 200 m2 or located on slopes and marshy soils.

Such structures require engineering geological surveys of soils, the development of a technological map for the implementation of a concrete blind area and the installation of a functional drainage system. These conditions can only be qualitatively met by specialists with the necessary set of laboratory and engineering equipment.

When deciding to make a blind area yourself, you need to really weigh your capabilities, the availability of machinery and equipment for labor-intensive work, for example, digging a trench and preparing concrete mortar.

If a home craftsman can do all this, then it is advisable to independently make a concrete blind area for the house, which will significantly reduce the owner’s costs for carrying out repair work.

Purpose of the blind area in the building

Some respected men do not fully understand the importance of this design. They consider the blind area purely as a pectoral and decorative element of the building facade, and ignore compliance with basic building codes.

The soil, in the thickness of which lies the supporting structure of the entire building, is a rather capricious and mobile substance. A soil layer saturated with water increases in volume and can behave unpredictably: shifts in soil layers, swelling, or vice versa, subsidence of the soil are possible.

Having a well-designed blind area around the house with your own hands will significantly reduce the negative impact of dynamic lateral soil loads. It should be noted the important functions that are assigned to the design of the blind area of the building:

- protects the soil from waterlogging and negative impacts on the foundation structure;

- drains wastewater and storm water from the structural elements of the foundation and walls of the building;

- Thanks to the blind area, the house construction has a complete look. The blind area stylishly emphasizes the outline of the building;

- a well-executed design of the blind area is an additional contour for insulating the foundation or basement;

- The blind area is a pedestrian path for moving personnel around the site.

It should be noted that the blind area is a fairly aesthetic and functional element of any house construction.

Common mistakes

Inexperienced builders often make the same mistakes when building a blind area.

Here are the most common of them:

- insufficient width : water draining from the roof will fall on open ground, be absorbed into the ground and gradually destroy the foundation

- low slope of the surface and, as a result, accumulation of water in the area of the foundation

- violation of proportions when making concrete: measuring components by eye often leads to the preparation of low-quality mortar and cracking of the concrete blind area; through the cracks formed, water will freely penetrate into the soil, and there will be little benefit from such a blind area

- lack of a waterproofing layer that protects the soil from moisture penetration

- lack of insulation : during frost heaving, the foundation will begin to collapse due to the formation of cracks; therefore, it is not worth saving on heat-insulating materials

The author of the following video shares his own experience in replacing an old blind area on loamy soil:

VIDEO: Blind area at home, doing it right!

Blind area around the house: types, structure, schematic drawings, instructions on how to do it yourself correctly (30 Photos & Videos) + Reviews

Features of working with various materials

Today there are quite a lot of types of materials and methods of carrying out work. Each of them has its own characteristics, advantages and disadvantages. Installing a blind area around the house is a stage in construction for which every detail is important.

Concrete coating: features of work

This method is most popular among the population due to a number of positive properties:

- Relatively low cost of material.

- A concrete blind area provides reliable protection of the foundation from moisture.

- Simple rules for working with concrete.

How to work correctly with this type of coating:

- The pit is prepared according to the general scheme discussed above.

- Next, you need to prepare the markings using stakes and rope or fishing line.

- Prepare a “pillow” and a layer of waterproofing.

- Before pouring concrete, recesses are prepared for pipes and storm drains. The disadvantage of a concrete blind area is the inability to lay communications in the future.

- The next stage is insulation of the structure.

- Laying reinforced mesh is a distinctive feature of working with this particular coating.

- The formation of formwork and expansion joints is mandatory.

- The last stage of work is pouring concrete.

In addition to the scheme discussed, there are many ways to “harden” the coating: using a primer, liquid glass.

Tile covering

Reasons why you should choose this method of laying the coating:

- Long service life subject to construction technology.

- No special construction skills required.

- The technology does not involve the use of a reinforcing layer, which significantly reduces material and labor costs.

- A wide range of textures, shapes and colors of paving slabs.

- The covering is easy to disassemble, for example, for laying communications.

There are some features for working with tiles as the main coating:

- The sequence and composition of the “cushion” changes: compacted soil, wet clay, a layer of sand, fine crushed stone and again a sandy covering.

- Before laying the covering elements, borders are installed: ordinary, decorative, curly (at the choice of the home owner).

- For borders, a solution of cement, sand and crushed stone is used, which is laid on the bottom of the pit.

- A layer of waterproofing film is laid on top of the crushed stone and always in two layers.

- The layout of the tiled elements depends both on the shape of the tile and on the imagination of the builder. Cement mortar or ready-made granular mixtures can be used as the underlying surface.

Decorative tiles successfully complement almost any style of garden interior, so for the aesthetic design of the yard you should give preference to this material.

Pros and cons of building on your own

Concreting a blind area is a process that requires a significant investment of labor, money and time. Therefore, implementing such a design on your own will provide significant savings to the family budget. When carrying out a step-by-step process of filling the formwork with concrete mortar, it proceeds without difficulties and does not require special construction experience.

Advantages of pouring a concrete blind area yourself:

low operating costs, while creating the same consumer properties, making concrete blind areas durable and simplifying their maintenance;- many design options - today there are many color and texture effects that create an expensive look for the cement base;

- Properly processed and hermetically installed concrete is practically resistant to water;

- creating an anti-slip surface;

- creation of a heat-resistant structure.

The disadvantages of installing a blind area yourself appear with large dimensions of buildings, marshy soils and sloping terrain of the location of the house. In this case, special engineering solutions, calculations and development of an individual flow chart for the work will be required.

You will find a lot of important and useful information about the construction of concrete blind areas in this section.

Profiled membrane covering

A new direction in construction, which is gaining popularity due to its original interior and easy way of creation. Sequence of work:

- Trench preparation is carried out according to general rules.

- The profiling membrane is placed on the bottom of the pit and compacted.

- A layer of waterproofing film is laid on top of the material.

- Next, a drainage layer is formed: layers of crushed stone and sand.

- The next stage is the formation of fertile soil in which plant seeds or lawn grass are planted.

In the middle of such a covering, you can place small concrete slabs or decorative tiles in the form of a path.

Pouring the solution

Pouring and leveling the solution

The order of pouring the solution:

- Since the concrete layer is small in height, the correct pouring of the blind area is done in one step

- Wooden cross bars serve as beacons when pouring, with the help of which the concrete is leveled. To do this, use a metal rule (a tool in the form of a long metal strip) or a flat board

- To avoid the formation of voids after pouring, the solution is compacted with a shovel or metal pin

- After pouring, the concrete is covered with film or a damp cloth and left to dry for a week. During all this time, it is periodically (preferably a couple of times a day) watered with water. This will ensure uniform drying of the concrete and protect it from cracks.

- The formwork is removed no earlier than after a week . But concrete gains full strength only after a month

- To enhance the waterproofing properties of concrete, after the solution has completely set, it is better to iron it . This can be done a couple of hours after pouring using a still wet solution. To do this, sprinkle it with dry cement M400 in a small 3-7 mm layer and spread it evenly over the surface.

It is highly not recommended to pour cement mortar onto a layer of sand. Such a blind area will definitely shrink and crack. Therefore, the pillow is made from a mixture of sand and crushed stone. Clean sand is used only for leveling when making paving areas.

Why is a blind area necessary?

The blind area is designed to perform the following important functions:

- protecting the foundation of the building from destructive factors such as moisture, plant roots, and so on;

- drainage of rain or melt water from the walls of the house into the drainage system, for which the blind area is equipped with gutters for drainage - this design reduces the risk of dampening of the foundation;

- increasing the aesthetics of the appearance of the house, giving it harmony and completeness;

- reduction of heat losses in the cold season.

In addition to fulfilling its main purpose, the blind area can additionally be used as a path around the perimeter of the house. Paving slabs are also laid on the concrete blind area.

Insulation of the blind area with extruded polystyrene foam

To insulate the blind area, polystyrene foam is used. This material is highly durable and fits under the screed. Insulating the blind area with extruded polystyrene foam prevents freezing of the soil, and, accordingly, the entry of cold into the house. Insulating the blind area is important for rooms where a basement or cellar is provided.

Drainage issues

To ensure effective removal of precipitation, the blind area is equipped with a drainage system. The design is elementary in its execution:

- an asbestos-cement pipe with a diameter of 10 cm or more is cut lengthwise into 2 parts. A grinder is suitable for cutting;

- the resulting pipe halves are laid along the perimeter of the blind area close to it;

- In the corners of the blind area at the junction of the pipes mentioned above, solid drainage systems are placed. The same asbestos-cement pipes will do. Trenches are dug to accommodate them. Select the dimensions of the pit so that there is at least 5 cm of free space on the sides and top of the pipe. First fill the bottom of the trench with a 5-centimeter layer of sand and compact it. The pipes themselves are wrapped in geotextile and diverted towards the structure to collect wastewater.

The specific option depends on the individual characteristics of the site arrangement.

The described drainage looks like this.

To improve the appearance of a concrete blind area, it can be tiled or decorated with other material of the owner’s choice.

Laying paving stones

Laying a blind area from paving stones

Procedure for laying tiles:

- Laying tiles starts from the foundation. It’s more convenient to do this on your own, so as not to damage the compacted cement-sand cushion

- Each tile is leveled with a building level and adjusted to the adjacent one using a rubber hammer. To avoid damaging the paving stones, this must be done through a wooden block. If the tiles lie unevenly, add a small layer of cement and sand underneath.

- It is better to fill the gap between the tiles with plastic crosses. The size of this gap is 2 mm

- Trimmed tiles and edging paving stones (used when there is no border) are laid last

- The joints are grouted with the same cement-sand mixture that was used to fill the pillow. After grouting, sweep the surface with a broom so that the mixture is well distributed in each of the seams, and then spill with water

Standards and technical requirements for the blind area

There are no official regulatory documents regulating the requirements for blind areas in our country. Some papers only mention the need for its arrangement, slope angles and some other data. But the Russian and European experience in building houses accumulated over the years allows us to determine a number of requirements for such a structure:

- The parameters of the blind area of the house are selected based on the type of soil. For sandy soil, the width of the tape should be around 70 cm, and for clayey soil - 100 cm. On subsidence soil of the first type, this parameter should be at least 1.5 meters, and of the second type - 2 meters.

- If a pit was dug during the construction of a building, then the structure should extend beyond its boundaries by 40 cm.

- The angle of inclination of the tape is selected from the range from 92 to 94 degrees from the building facade.

- If a drainage system is not organized, then the width of the blind area should exceed the projection of the side overhangs of the roof by 20 cm or more. This requirement is purely advisory.

The procedure for preparing the underlying layer for the blind area

This layer is an important element and is responsible for the reliability of the entire structure. Therefore, in order not to make mistakes at the initial stage, it is necessary to comply with the following requirements:

- Be sure to remove the plant layer and part of the soil. The depth of the trench must be at least 30 cm.

- Impregnate the prepared surface with herbicide. This is necessary so that there are no plant elements under the blind area. After all, they are capable of starting the destructive process of the protective layer.

- The bottom of the trenches must be sloping and compacted.

- We form the underlying layer according to the specified slope and compact it. The pillow should be hard and perfectly smooth without holes or bumps.

- Only after this we lay a protective layer and form drainage ditches.

These were the main and important nuances that must be observed in a clear sequence.

If the blind area requires repair

If the concrete begins to deteriorate, then, depending on the degree of damage, the restoration technology takes the following form:

- if the cracks are local (up to 30% of the surface) and not wide, they are filled with cement paste (the proportions of cement and water are 1:1);

- for local repairs and wide cracks - they are expanded, the visible reinforcement is treated with an anti-corrosion compound, and sealed with a repair polymer cement mortar;

- in case of crumbling and delamination, weak areas are cleaned and a layer of cement-sand mortar screed is poured around the entire perimeter of the house (with the preliminary installation of a new curb and the installation of a reinforcing frame).

What is the importance of a blind area for a building?

With the help of a concrete blind area, you can significantly protect the structure from the adverse effects of moisture. After all, you cannot achieve a similar effect with any other material. It is known that the following natural factors can affect the foundation of a structure:

- Increased moisture levels;

- Quite low temperatures;

- Various mechanical damage due to soil swelling.

In order to counteract these unfavorable factors as effectively as possible, the foundation of the structure is of great importance. Therefore, it is necessary to protect it as thoroughly as possible, and also reliably with the help of a blind area.

The process of pouring the blind area