You can't do without a ladder. It is needed to move between floors. But its capabilities are much wider than the banal execution of its main function. After all, a staircase is also an interesting means of artistic expression. A way to make the interior bright and memorable.

The staircase to the second floor is one of the key elements of a country house.

Advantages and disadvantages of interfloor stairs in a private house

In a building with more than one floor, there is always at least one staircase. The only way to avoid dealing with them is to build a one-story house. Why might the prospect of being limited to one floor seem tempting to a not very experienced builder?

- Reluctance to delve into the complexities of design

The manual for making stairs contains a whole list of rules and prohibitions, a long formula for calculation and many incomprehensible words. It can be scary. But there is no need to be afraid. If you wade through a bunch of mysterious terms, it turns out that the problem can be solved without two higher educations.

This is a significant part of the house, which indicates the idea of style and sets the desired mood for the interior.

- Saving usable space

At first glance, the space occupied by the staircase simply disappears. You can’t place cabinets there, you can’t put another guest sofa, you can’t set up a workspace. At the same time, it, like the rest of the house, has to be heated, lit, and spent time and effort cleaning it.

On the other hand, a staircase and, accordingly, a second floor is an opportunity to double the living space without encroaching on the space of the garden area. Therefore, talk about saving space seems very controversial.

Often today it is distinguished by greater functionality, since in addition to its main purpose it also carries other loads.

- Saving money

It’s difficult to argue here. The construction of a one-story cottage costs less than the construction of a two-story cottage of the same area using the same building materials.

Of the three arguments against stairs, two do not stand up to scrutiny. Conclusion: It is foolish to avoid this design element at all costs. It allows:

- increase the number of residential premises;

- leave more free space in the garden area;

- make the interior more interesting, unusual, aesthetically attractive.

It is often an element of zoning space, delimiting it into separate functional areas.

In most cases, the question of whether to make a ladder or not is, in principle, not worth it. Simply because it is immediately obvious that all the planned premises will not fit on one floor.

Selection and manufacturing principle

First of all, you need to choose the style of the future product and its shape. Some craftsmen believe that interfloor wooden staircases are ideal for private or country houses, but in modern construction they have recently begun to give preference to other materials that have superior qualities. Modular designs that combine different elements have become especially popular. If desired, you can build a modular staircase with your own hands.

Do-it-yourself modular staircase: pros and cons of the solution, design options

Peculiarities

- All modular designs are characterized by low material consumption.

- They have great strength and, when properly manufactured, can withstand 250 kg per section.

- Usually, an interfloor wooden staircase is decorated with various decorative elements and panels, but modular products do not have free space for such decorations, and therefore designers try to give them a magnificent look using the beauty of shapes and colors.

- Separately, it is worth noting the fact that the service life of such stairs is very long, and the cost of their production can be considered minimal.

Advice! If you wish, you can purchase a ready-made modular staircase, but you should not count on its uniqueness and exact compliance with the dimensions of the house.

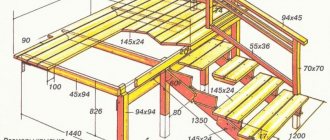

Project

Conventional interfloor modular stairs are made of metal. At the same time, special fasteners are made as steps of the stairs, on which treated wood, natural stone or other available material will be installed.

Therefore, before starting production, it is necessary to develop a project.

- It must indicate clear parameters of all metal structures and their relationship with the dimensions of the room.

- Particular attention should be paid to ensuring that the interfloor staircase for a private house is securely tied to the walls, floor and ceiling. This is due to the fact that these parts will bear the entire load.

- It is also necessary to think in advance about the method of installing the steps. Typically, for these purposes, metal coins with holes in them are used, which are welded in the area of their intended location.

Advice! If there are no specific skills that are necessary to create a project, then you can use ready-made developments, changing them to suit the appropriate conditions. This will also save time.

Working with metal

When creating different types of interfloor stairs, you have to deal with different types of metal processing. These include cutting, grinding and even welding. Therefore, when starting this type of work, you must have the appropriate tool and have certain skills.

You may also need various measuring instruments that will allow you not only to determine the dimensions, but also the location of the product in space. This is especially important when screw structures are created, since the slightest error in the calculations can result in a defect that will not only interfere with normal operation, but can also cause injury.

The finished product is attached to supporting structures using anchor bolts or other durable connecting elements. Quite often, when constructing walls, parts of metal reinforcement are installed in them, which protrude to the surface and can serve as a support for the welded joint. Often, a modular interfloor staircase is simply concreted at the base, which can be an excellent solution, as it will give the structure additional strength.

Features of simple stairs for home

Stairs to the second floor in a private house are different. The easiest way is to take a standard version in the form of the letter “P”. The same one that is used in the vast majority of apartment buildings. Standard steps are 15 centimeters high and 30 centimeters wide. March to the middle of the floor, then a small rest area, turn 180 degrees, another march.

Among the advantages of this solution:

- minimum calculations;

- easy to find ready-made drawings;

- there is no need to invent anything.

Not only the material of manufacture matters, but also the footage of the occupied area, as well as the shape and location of the structure.

There are also disadvantages. The standard version takes up quite a lot of space - you can make the staircase much more compact. From an aesthetic point of view, using the simplest path is also not optimal. There are significantly more beautiful and interesting stairs.

By type of steps: closed and open

Closed stairs are called treaded stairs. Most often, such a marching device is found on stairs on racks, when the step is attached to the saddle, the upper part to the paw, and the open riser to its vertical part. Stairs with spacers are less often made in the form of closed steps.

If there are no treads in the design of the steps, then these are open stairs.

The advantage of closed stairs is that the internal volume can be used as a small pantry, cabinet or storage system with drawers.

The advantage of an open design is that it is visually airy and light. Although these stairs do not provide any additional function, they do not clutter up the space.

A stepladder is a type of open structure.

The peculiarity of the design is that each crossbar has a specific shape and is designed to support only the right or left leg. This means that when ascending or descending, you need to overcome one rung. This, of course, requires some attention and getting used to, but due to the steeper angle of descent, this type of staircase “occupies” much less usable space.

Standards and requirements for stairs between floors

In the Building Codes and Rules, a fairly large section is devoted to stairs. The most important things you need to know from there are related:

- With the width of the stairs

It must be at least 80 centimeters. And no less than the width of the doors that lead to the staircase.

- With step height

This value should be in the range of 12-20 centimeters. The most convenient is 15. This height is the most common.

- With step width

For a residential building or apartment, this parameter should be at least 25 centimeters. Usually they make 28-30.

- With the dimensions of the recreation area

It is also called the landing. And its length must be at least 130 centimeters.

- With railing height

The minimum height is 90 centimeters.

According to the type of execution, the staircase to the second floor is a stationary structure, which in most cases is securely fixed to the floor.

These are the basic restrictions recorded in SNiPs. Staying within their framework, making a ladder that is easy to use and safe is not so difficult.

Where to post: basic rules

Installing stairs to the second floor is a very individual process that depends on the size, layout and height of the ceilings in your room. The most popular place for stairs is still the hallway, especially in spacious detached houses. This way, when you enter your home, you have immediate access to all rooms without wandering down hallways.

The second most popular place to install an elevator is the living room. This is useful for medium-sized buildings if the ground floor leads to a separate room, such as a bedroom. In the hall connected to the kitchen, the staircase can be used for zoning.

Types of interfloor stairs

Existing standards leave quite a lot of freedom. For example, you can experiment with the configuration of the stairs.

Straight

The most commonplace option is a straight staircase. These are often found in dachas.

Why is this rarely done in cottages for year-round use?

If you adhere to the standards, such a staircase turns out to be too long. Even with the minimum width of the steps, we are talking about 4.5 meters. Plus at least 100 cm in front of the first step and 130 for the top landing. The layout does not always allow a structure of such dimensions to be seamlessly integrated into the interior.

Direct installations are the most common and popular because they are convenient, functional, and the most cost-effective.

Dacha owners, as a rule, simply ignore the rules. They reduce the width of the steps to dangerous values, raise their height, and create an ascent with a completely crazy slope. It is dangerous to use such ladders. Especially when it comes to young children and elderly people.

L-shaped

This type is also called “angular”. Looks like a straight flight, a landing, a 90 degree turn, another straight flight. In plan it resembles the letter “G” (or, if we turn to the Latin alphabet, “L”).

A corner staircase is basically a straight staircase that has a change of direction in the middle.

Important! A corner staircase is usually the easiest to fit into the layout. It is easy to use. Her artistic potential is extremely high. The only drawback is that such a staircase does not fit well with classical styles, where symmetry rules the roost.

U-shaped

This type is also called “rotary”. In plan, it resembles the simplest option in the shape of the letter “P” - a flight, a landing, a 180-degree turn, another flight. But U-shaped stairs do not have an intermediate landing. Instead, there are winder steps, each of which in plan resembles an elongated trapezoid. Together they look like an open fan.

This installation is functional and much safer, since the wide possibilities of the flight of stairs limit the number of steps on which someone can fall.

Important! Why can a turning staircase be a convenient solution? Its length is shorter than that of the more traditional U-shaped or L-shaped options. Consequently, it takes up less space and is easier to fit into the interior. The downside of this route is that climbing to the very top without intermediate rest areas is physically more difficult.

Spiral

Such staircases are often called “spiral” staircases. They are associated with medieval castles. However, they were also used everywhere in medieval residential buildings.

Important! A spiral staircase consists of trapezoidal steps twisted in a spiral around a single axis. Its main advantage is that it takes up little space. The downside is that it is almost impossible to transport large items and furniture along it.

In the Middle Ages, for example, bulky loads were lifted to the upper floors through windows, using a system of pulleys and cables from outside the building. You can still see hooks designed for this purpose on the facades of houses in old European cities.

The compact design here is centered around one pole, so that if you were to look at it from above, you would see a perfect circle.

There are versions of spiral staircases that do not have this drawback. Resembling a wide arc in plan, rather than a circle tightly twisted around a central axis. However, such curved stairs, on the contrary, take up a lot of space. They are sometimes made in public buildings with a large hall - in large hotels, theaters, exhibition halls. In private cottages - almost never. It's very wasteful.

Double

Double are those varieties of this structural element in which one of the marches is duplicated. For example, it might look like this: two symmetrical lower flights approach a common landing from different points. Then another march leads up from there. Or vice versa. There is one flight of stairs leading to the intermediate platform. And from there two flights of stairs diverge in different directions.

It includes one wide span, which then splits into two smaller spans running in opposite directions.

Important! In huge country palaces, grandiose double staircases are used to bring together two wings. Or to play up the hall space in an interesting way. In a situation where square meters are in severe shortage, such solutions will most likely have to be abandoned.

Non-standard

The plan has the shape of a fancifully curving curve; resting on arched stringer beams; reminiscent of designer parts protruding directly from the wall. And so on. Human imagination is limitless. There are hundreds of examples of custom stairs on the Internet.

You should have an idea of what type is best for your home.

Before turning an impressive picture from the Internet into reality, you should evaluate your capabilities. Such a staircase cannot be assembled from ready-made parts according to standard drawings. It is quite possible that some parts of the structure will have to be ordered. Or make it yourself.

Types of staircase structures

If we consider stationary stairs, then according to the nature of fastening the flights of stairs, the following design options are distinguished:

Marching

A common version of the staircase, designed taking into account the biomechanics of movement and providing comfortable, safe movement. They consist of 3-15 tiers of stairs. If the maximum number is not enough, the height is divided into two openings, between which a small platform or ladder is installed. Such buildings are already called two-story.

Stairs vary in shape and can be straight, rotating (L-shaped or U-shaped) or curved. When determining this parameter, you should take into account the area of the room, the height of the ceiling, and the location of the first floor.

Depending on the type of supporting structure, there are two types of stairs: longitudinal and longitudinal-transverse. In the first case, the steps are laid on top of the beam, and in the second, special grooves are made from inside the load-bearing element.

You also need to select the type of tread. Parts with protectors look more massive and will fit perfectly into a classic interior, while parts without them, due to their lightweight design, fit well into a modern home.

Overall, there is a wide range of stepladders to choose from, and even for small spaces it is possible to find a suitable unit or combine it with other elements.

Stringers

Beams are support beams with a tongue for each crossbar. This is one of the most common types of staircase structures. The bevels do not have to be used in pairs. There are stairs with one central load-bearing element.

They are installed when it is necessary to “save” space. Two stringers are standard.

In the case of wide stairs, three stringers are needed so that the steps do not collapse in the middle. As a rule, for stairs wider than 1.3 m, a third stringer is used.

The stringer is made of a metal profile or wood.

Boltsy

In this type of construction, the load-bearing wall is the support for the stairs. The steps are attached to it with bolts (crossbars). The resulting composition looks light, weightless and fragile, but in fact it is strong and durable and can withstand a load of more than a ton.

Thanks to the bolts, if necessary, the height of the steps can be adjusted even after installation. The staircase is equipped with a handrail for safety.

On the bowstrings

Rails are load-bearing beams, similar in some respects to stringers. However, they can only work in pairs. This is due to the nature of the fastening of the steps - they are installed in the internal grooves of wooden beams or on support plates welded to metal profiles.

Stairs on racks look visually more compact, but they are more difficult to install - the racks must be precisely installed so that the grooves or plates fit perfectly in pairs with each other.

Console

Technically, these are single-string stairs, the steps of which are firmly attached to welded profiles or vertical stringers (bolts). The stringer itself is a metal load-bearing element that is attached directly to the load-bearing wall using anchor bolts.

Then the string is hidden under the finishing (plasterboard, plaster), and the steps are attached to the profiles. Handrails usually do not function as a load-bearing element, but sometimes they are reinforced enough to carry part of the load.

Carefully. For monolithic reinforced concrete walls, as a rule, you can use direct fastening of each step with anchors. However, this option is rarely used in private construction.

Screw

The operating principle of these structures is very simple: the steps are mounted on a fixed crossbar, which rises upward in a spiral. They do not take up extra space and are quite compact.

The main reason why spiral staircases are inferior to medium-height staircases is the difficulty of movement caused by the lack of solid support. It is not recommended to install such an instance in a house where there are children or elderly people. The following parameters are considered optimal: the central width of the steps should be at least 20 cm, and the widest part should be no more than 40 cm.

Otherwise, spiral staircases are an excellent option for both modern and classic styles. Their spiral shape makes them a key element of the interior, and products of various shapes - from square to octagonal - will help add variety to the decor.

What materials are interfloor stairs made of?

The choice of material also leaves enough room for maneuver. In mass construction, reinforced concrete is almost always used - prefabricated or monolithic. Or, much less often, metal. In a private home, there are many more options available, which can also be combined with each other.

Today, staircase structures are constructed from various raw materials.

Tree

A wooden staircase to the second floor is the easiest to make. Boards and timber are sold at any hardware store. This soft material is relatively easy to work with. The result is reliable and durable. The aesthetic appeal of wood structures is largely determined by the final processing of this beautiful natural material.

Wood fits perfectly into any of the design branches, be it modern, classic, ethnic or vintage.

Important! Wood combines well with other materials. For example, you can combine wooden steps and railings with a metal supporting frame and elegant chrome-plated railings. The combination of wood and glass is also relevant.

Metal

The beauty of this option is that, like a construction set, it can be assembled from ready-made elements - angles, channels, pipes of different diameters and sections, rods, sheets. The disadvantage is associated with the specifics of metal as a means of artistic expression.

The use of metal for stairs allows you to create a reliable and durable structure.

Open metal structures are used in high-tech, constructivism, and loft. Not everyone likes these cold modern styles. To soften the harsh uncompromising nature of this material, it is painted in bright colors and combined with wood, glass, and stone.

Stone

In the modern world, interfloor stairs are not made of stone. It is too technically complex, labor-intensive and expensive. Those who want to acquire a beautiful stone staircase usually take some other material that is easier to work with as a structural basis. For example, reinforced concrete or steel. And stone or its realistic imitation is used for cladding. It looks luxurious.

Depending on financial capabilities, artificial or natural material is chosen.

Concrete

Reinforced concrete is an extremely common material for the manufacture of stairs. Its only problem is that it requires additional design at the final stage.

Concrete products are not used in every private building, since the material is heavy and massive in appearance.

Important! Typically, porcelain stoneware, stone, tiles or other high-quality dense materials with good strength characteristics are used for cladding steps. Concrete is not subjected to additional processing only in such modern styles as loft, hi-tech, constructivism.

For railings of reinforced concrete stairs, metal, wood, glass, or a combination of these are usually used.

Glass

At first glance, transparent glass steps seem too fragile and unreliable. However, modern construction capabilities make it possible to make such a staircase strong and durable.

Glass has the ability to make any structure lighter and airier; it brings a feeling of spaciousness to the interior, even with limited space.

Important! Most often, glass plates of steps are either placed on a metal frame. Or they can be mounted directly to the wall using console mounts. The latter looks fantastic.

The most interesting options are obtained by combining different materials.

Design tricks

The choice of design of a structure is one of the most important moments in its design. It is the staircase to the second floor that guests see when entering the house, because most often it is located in the hallway. That is why it must fit harmoniously into the overall interior.

Important! The staircase connects both the first and second floors, so it should be in harmony with the interior on the 1st and 2nd floors. Here you can either choose a combined color scheme or make it contrasting, highlighting both rooms with an unusual color.

Staircase in a modern interior

Rooms in a modern style are characterized by minimalism, this also applies to the stairs. All lines should be strict, no unnecessary decor, restrained colors. Metal and glass are ideal materials; wood is less suitable (not always). Sometimes there are concrete structures.

You can choose any design, depending on your taste.

A modern interior is characterized by the absence of railings. Sometimes they are mounted on the wall. Also, a distinctive element of such a design can be a cabinet with flowers or a picture on the landing between floors.

Classic style

The most suitable types of construction for such an interior are marching, on bowstrings or stringers; a spiral staircase is rarely found. For finishing it is recommended to use natural materials (wood or stone).

Wooden structures with carved railings or forged ones are especially popular. They look very elegant and interesting. Harmoniously complement any interior.

Structurally, stairs in the high-tech style are made on rails or built into the wall. The predominant materials are metal, glass, and their combination with painted wood. They are compact, have narrow steps, and are light and unobtrusive. Quite often, wooden stairs in this style are successfully combined with glass or chrome safety elements - railings and handrails.

Components of stairs

A staircase can consist of different parts, depending on its structural type. There is only one mandatory component that you cannot do without. Steps.

In addition to them, there may be:

- Kosour

This is the name of the inclined beam on which steps are mounted on top. It is this element that takes the load. Thanks to him, the entire structure holds together. There may be one stringer, in the middle. For a small narrow staircase in a country house this is usually enough. Wider options require two or even three stringers.

- Bowstring

This is an alternative to a stringer. It is installed not under the steps, but on the sides. The string takes the load through the side faces of the step elements.

The main components of stairs are supports, steps, bowstrings, stringers, rails, posts and railings.

- Other types of fastenings to the ceiling or walls.

Non-standard stairs are often created using non-standard fasteners. This can be embedding directly into the thickness of the wall, brackets, anchors, and so on.

- landing

The area between flights of stairs intended for recreation.

- Fencing

They, in turn, consist of vertical posts (or flat sheets installed vertically) and railings.

Sometimes doorways are also mentioned in the context of this topic. If the staircase directly abuts the door, then you must immediately carefully consider the issue of their connection. Making sure the door won't open onto the stairwell is a safety issue.

If the height of the stairs is more than 45 cm, it must have railings.

Important! You need to choose the structural type of the staircase - that is, how and what it will be attached to - in parallel with the selection of material, immediately after determining the type of configuration. These two points are interconnected. For example, it is better to make glass with cantilever fastenings or on stringers. Wooden ones are often made on a bowstring. Metal is almost always frame systems with stringers. And so on.

How to design the space under the stairs?

To somehow compensate for the impressive size of the staircase, you can combine it with another functional object, using the empty space. This applies to stairs located in the middle of the floor against the wall. They are more complex, require detailed measurements and careful planning, but ultimately allow you to make the most of every square meter of the room.

The space under the stairs can be used as a frame for cabinets. This solution is suitable for both the hallway (for storing clothes and shoes) and the living room (for a home library and household items). The staircase can be designed as a wall in the living room, the protruding elements of which serve to move between floors.

Connoisseurs of luxury drinks can organize a large collection of wines by closing it with glass doors and installing lighting. The newly created alcove can accommodate a small sofa, a cozy seating area or seating area, and shelves can be placed on the side walls.

The space under the stairs is ideal for creating a separate room, such as a storage room, office or small workshop. Any child will be delighted with such a secluded children's playroom. Using these ideas will allow you to take a different look at the staircase in your home, turning it from a bulky object into a functional solution.

How to make a staircase to the second floor with your own hands

Once there is an understanding of what exactly you want to get, the next question immediately arises - how? How to make a staircase to the second floor? Where to begin?

Nothing should interfere with movement along the steps, be it a large overlap of one step over another or insufficient width.

How to place a ladder

The first step is to analyze the initial situation. Need to:

- take measurements of the room where the staircase is supposed to be built;

- measure the height between the floor levels of the first and second floors;

- calculate how many steps will be needed to climb to this height (for example, at the rate of 15 centimeters per step);

- calculate how long such a staircase will take;

- add to the resulting value the size of the rest area, the distance in front of the stairs at the top and bottom;

- see how an object of this size fits on the plan.

Creating a project with drawings and diagrams

After the approximate configuration of the staircase and its position in space have been determined, it is necessary to draw it to scale.

Important! It is imperative to make a plan with the exact location of the steps, landing, fences, and fasteners. Section and detailed images of the most difficult places from a constructive point of view. For example, the junction of the stairs to the opening in the floor slab of the second floor. And other problem areas.

Such a detailed project is needed to estimate the quantity and cost of materials. And to understand exactly what needs to be done.

You cannot make the steps too narrow; different widths and heights of the rises of the flight are strictly unacceptable.

Required tools for installation

The list of installation tools varies greatly depending on the materials that are planned to be used. Wood requires one set of equipment, concrete - another, glass - a third. The main thing is to make sure that everything you need is available before starting work.

Assembly and installation of stairs

Regardless of the type of material, installation work is carried out in the following sequence:

- installation of load-bearing structures;

- installation of steps;

- fastening risers (if they are provided for in the project);

- installation of fencing;

- final facing.

If the structure has a landing, its width should match the width of the flight, even if it is a simple compact staircase.

For country houses, sometimes it seems more rational to purchase a compact extension ladder and climb into the attic with its help. But, of course, this option is unacceptable for permanent use.

Formulas for calculating stairs

NickVasAssistant moderator FORUMHOUSE

...When calculating the stairs, the main dimensions of the flight of stairs are determined, which best correspond to the convenience and safety of movement. The best option is a wide and flat staircase. But in practice, in each specific case one has to proceed from the parameters of the space left for the stairs. Sometimes you wonder how you can push 18-20 steps into a given niche space.

The main parameters of the staircase include the height of the rise, the type of staircase, the plan area, the steepness, and the number of steps. All these parameters are not independent, that is, they cannot all be assigned. For a straight staircase, the height of the rise and the steepness determine the plan area and, conversely, the plan area and the height of the rise determine the steepness. When designing, you must immediately set the values of the defining parameters. After this, you can calculate the slope, which will determine the number of steps.

Basic formulas for calculating stairs.

- Average step formula (S), also known as Blondel's formula: S = a + h×2 (600 ≤ a + h×2 ≤ 640).

- Safety formula: a + h = 460 mm.

- Convenience formula: a – h = 120 mm.

Practitioners prefer the golden ratio, which duplicates the SP.

Sergey0103FORUMHOUSE Member

All the calculations and formulas given are the theory of relativity, plus or minus a kilometer. All calculations are made exclusively based on the existing situation. For the concept of convenience of treads and risers, there is a golden ratio - this is a 300 mm tread and from 150 to 170 mm, a riser, a step thickness from 40 mm to ease of processing. The height of the riser depends solely on the level of inclination of the stringer. The clearance depends on the height of the walker, individually. A dwarf will need a riser with a height of 120 mm and a clearance of 1000 mm.

Designing staircase lighting

The staircase should be well lit. Especially at the entry and exit points. Hanging or built-in spotlights will fit perfectly there.

The type of structure is selected based largely on the footage of the first floor.

Important! A good solution is to illuminate the steps using LED strips. They are installed at the top of the riser. You can also make strip lighting on the outside of structures. This will highlight the staircase in the interior space.

An example of calculating a staircase with sketches and visualizations

NikVas, who specializes in stairs professionally, offers ready-made calculations in his topic.

NickVasAssistant moderator FORUMHOUSE

Opening 1020×1790 mm. Wooden staircase on bowstrings with winder steps.

Sketches and visualizations.

Working drawings.

How to make a winder from a regular step.

Finished staircase.

NickVasAssistant moderator FORUMHOUSE

Opening 1855×1905 mm. Metal frame.

Useful tips for building a homemade staircase

You can make an unusual, beautiful, comfortable staircase with your own hands. You just need to strictly adhere to the correct sequence of actions, and not move on to the next stage before the previous one is completed. Consistency, a calm and thoughtful attitude, and accuracy are the three qualities needed to do this job.

Modern stairs look decent and blend harmoniously into almost any interior of a country house or cottage.

Please note that professional designers, when presenting to the public the interior they have developed, for the presentation in 40-60 percent of cases they take a photo where the staircase is visible. Because they know which element of the decor looks most impressive.

About the safety of stairs

The staircase must be designed by a specialist. You should pay special attention to its safety and do not neglect the following rules:

Classic, clearly defined spiral staircase

Smooth rotation along the entire length - both beautiful and convenient

The simpler the shape and the fewer turns the staircase has, the more convenient it is

Elegant and comfortable, but it’s better when the railing is located on the right

Classic straight staircase with a convenient handrail along the wall

Installation of a marching wooden staircase

Installation of a wooden interfloor staircase begins with the manufacture of stringers (or bowstrings), treads and risers.

Layout of a staircase along the wall with dimensions indicated

The treads are cut from the board according to a previously prepared template. Their standard thickness varies from 30 to 40 cm. If you do more, it will be an unjustified consumption of materials and make the structure heavier. Risers perform a decorative function in a building. Therefore, you can save on them by using a 10-15 mm board.

Stringers are made from a solid board that is free of any defects. Both stringers must be identical so that the staircase does not turn out asymmetrical and skewed.

Marking the stringer

Option for making a stringer with fillies

Assembling a bowstring with stiffeners

Frame assembly

Installation of stringers begins with making cuts on the floor beam located at the top of the flight of stairs. Sometimes the cuts are replaced with metal stops, which should be attached to the vertical floor with anchors. Regardless of which method you choose, the stringers must be firmly fixed to the ceiling.

Options for fixing elements

On the lower floor, along the line of the very first step, a support beam is installed in the floor. Anchors are used as fasteners.

Attaching the stringer to the floor

Installation of components

Installing the steps will not be difficult. The cutouts of the stringers are coated with glue and risers are attached to them, which then need to be leveled and secured with screws.

Attaching risers to stringers

Treads are laid on top and fixed to the risers and stringers. It is recommended to place polymer gaskets in the form of tapes under them. This will prevent squeaking from occurring as a result of wooden parts rubbing against each other.

Methods for installing steps on a stringer

Attaching the steps to the string

The function of the fence is performed by balusters, when installing them it is important to ensure correct evenness. For this purpose, install the upper and lower columns and connect them together with a stretched thread. It serves as a guide for installing other elements. Balusters can be attached with screws or self-tapping screws, which are masked with grout or plugs.

Fencing fastening scheme

The handrail is installed and fixed on the balusters. It can be wooden, iron or other material.

Finishing

After installation, all surfaces must be sanded, including hard-to-reach places, ends, and joints. Then the structure is treated with protective agents and covered with varnish or paint.

Fencing

The staircase can be decorated with or without railings. Here the choice is to the taste of the owner of the house. However, it is worth remembering that the stair railing is designed to ensure safe movement. Eliminating the risk of falls and injuries is especially important if children, elderly people, and people with disabilities live in the home.

If we refer to the standards, they read as follows:

- Structures with more than three steps must necessarily have railings on at least one side. In the case of stairs up to 1.2 m wide, railings are installed on both sides.

- Handrails are fixed on balusters (vertical elements), which should be placed at a distance of no more than 15 cm from each other.

- Railings and handrails must be made of high quality and be rigid, because the safety of movement on the stairs depends on this.

- The material used to make fencing parts can be very different, the main thing is that it is easy to process and does not require special care.

If you decide to make balusters in fewer quantities than required by safety standards, you will still have to install fencing elements between them. These could be metal strings or a grid.

Metal or wood is used to make handrails. In the first case, it can be stainless steel, brass or aluminum. Brass is more expensive, but aluminum cannot be called a durable metal. Lattice elements will fit more successfully into a loft-style interior, especially if the staircase is installed along a brick wall.

For a rustic style, the best option is a design with wooden elements. This material looks noble and allows you to make balusters of any shape and complexity. Some companies offer ready-made projects - beautiful stairs with sculptural carvings that do not require additional decor.

Some interior styles, such as hi-tech and minimalism, are characterized by the use of glass as the main material for stair railings. Such elements visually look like inserts, simultaneously acting as a transparent screen and serving as a support on which the handrails are held.

Article on the topic: Chair with transformation into a ladder: types of designs and features of self-production

It is worth noting that a person who first steps onto a staircase with glass partitions may experience a feeling of constraint or fear. However, this is only a first impression; such fences are quite reliable.

Calculation of system elements

The layout of the straight and rotary march structure is carried out according to the general principle. To calculate the stairs to the second floor, you need to measure:

- height (H) from the floor of the first floor to the floor of the second floor. If the finished floor is not finished, add the thickness of the screed, underlay, or floor covering to the resulting number;

- the length of the opening is from the end of the ceiling to the outer wall. Double-check from different angles. If the values are different, take the smaller one;

- opening width - the distance between the right and left walls. We double-check again on both sides and take the minimum size.

Let's calculate the angle of inclination

The slope depends on the area of the house and the height of its ceilings. A staircase with a slope of 30-36 degrees will be compact, but it will be difficult to go down it. For a slope of 40-45 degrees, you need a large room, since such a wooden staircase is quite bulky. The lower the inclination, the more dangerous it is to move along the march; the higher it is, the more space the structure takes up.

Correct calculation of the width and height of the step will ensure ease of movement up and down. The average human step is 63 cm, the step height is 2 times less (31.5 cm). The standard value is 30 and 15 cm, respectively.

We calculate the slope using the formula:

- 2x + y, where

- X - riser height;

- Y - tread width.

If the size of the steps is less than 14.5 cm, X does not need to be doubled. The lower the step, the wider it should be.

Ratio of inclination angle (in degrees) / tread size (w/h, cm):

- 30/ 28/16

- 33/ 26/17

- 37/ 24/18

- 41/ 22/19

- 45/ 20/20.

How to correctly calculate the slope in a simple way:

On a piece of paper, draw a right triangle in which:

- horizontal leg - horizontal projection of the base of the future staircase;

- vertical - height from floor to floor between floors;

- hypotenuse - the length of the march.

The acute angle at the bottom of the projection is the elevation angle. If its value is within the norms, you can begin to calculate the steps.

Let's count the steps

The slope of the march is 40-45º. Let's calculate the number of steps using the formula:

- 2A + B=60-64 cm, where

- A - riser height;

- B - tread width;

- 60-64 is the average human step.

Let's say A=14-17. We calculate the width of the tread B:

- 60-15x2 or 64-15x2 = 30 or 34 cm.

The lack of width can be compensated for by a protrusion.

We calculate the number of elements in a march:

height H/step height (riser) = quantity

The optimal riser height, recommended by SNiP, is 15-19 cm. If the result is a fraction, round to the nearest whole.

Let's assume H=280 cm. Let's calculate:

- 280/15 =18, 6

- 280/16= 17,5

- 280/17=16,4

- 280/18=15,5

- 280/19=14,7

In a march you can do from 14 to 19 steps (a larger value is rounded up, a smaller value - rounded down).

If there is an interfloor staircase with a landing, we plan a landing for the entire width of the opening, 1 m long, and place it on the drawing. Let's calculate the exact number of steps on one flight:

shaft length minus platform length / tread width

In our example it turns out:

200/25 (tread width according to SNiP) = 8

Given the existing dimensions, there are 8 steps each on the lower and upper flight and the ninth is a platform, which is considered as a step. In total, the staircase consists of 17 steps.

Let's calculate the step using the formula:

interfloor height (H) / number of steps = step height (riser)

Let's calculate using our example - 280/17 = 16.47. Round to 16.5 cm.

We got a comfortable staircase of 17 steps, with a step height of 16.5 cm and a tread 25 cm wide.

Since we rounded fractions during the calculations, we need to put the deviations somewhere. For example, an error of 0.03 cm in the height of the riser will go to the bottom step, which we will make shorter than the others by 5.1 mm (17x0.3).

We check the correctness of the calculations on the spot - we draw a projection of the steps with the given dimensions on the wall with a pencil. You will be able to find out if a window, door, or radiator is bothering you and adjust the calculations.

When the staircase is not completely located under the opening, it is important to consider the distance from the steps to the ceiling. When ascending and descending, a person should not touch his head to the edge of the opening. The parameter is relevant, as a rule, only for rectilinear single-flight structures.