It is not so easy to answer unambiguously the question of what is the best material to make a canopy in the yard, if only for the reason that you need to take into account several different factors. Including why you intend to build a shed in your yard. That is, what benefits are you going to get from this construction?

This of course does not mean that I am not going to give you specific advice on this issue. I simply suggest that you consider several of the most common options, and then draw conclusions.

What is the best material to make a canopy in the yard for practical reasons?

Currently, the choice of modern building materials is quite large. But the most popular for building a canopy are polycarbonate and metal profiles, which are often also called corrugated sheets or corrugated sheets.

These two materials have completely different characteristics, but both are successfully used for the construction of canopies.

Here we will compare them in terms of cost and operational parameters.

We just need to immediately decide by what criteria we will compare polycarbonate and metal profiles.

The most important to me are strength and durability, ease of installation, light transmission, appearance and, of course, price.

In addition, you need to take into account the material from which the canopy frame will be made.

So, let's start with polycarbonate.

How to do it yourself?

To make your own canopy over the porch, we have prepared a simple option for a canopy with a roof made of corrugated sheets or polycarbonate.

Step-by-step instruction

Work on a canopy made of corrugated sheets takes place in 3 stages:

- Preparing the base.

- Installation of the base.

- Roof.

Since the sheets are quite light, the base can be made of welded or forged metal, as well as wood. The latter is the easiest thing to do - you don’t need any special tools or skills, all you need is a saw, a small number of nails with a hammer or bolts with a wrench and a screwdriver.

- Measure the place where the visor will be attached.

- Draw the project on paper or in a special program on your computer, taking into account the sizes of all elements.

- File the required parts.

Important! The wood must be pre-treated with a protective compound!

- Assemble the frame.

- Attach it to the wall.

Important! If necessary, pillars are dug in from the outside - in this case, you need to start with them and not install the canopy until the concrete has completely dried.

The last thing is laying the sheets themselves. They are attached to the sheathing using self-tapping screws; two sheets are placed on top of each other with an overlap of one division.

Video

From the video instructions you will learn how to weld the base for the canopy and attach polycarbonate sheets to it:

Canopy in the courtyard of a private house made of polycarbonate: pros and cons

You probably know what polycarbonate is. But let's take a quick look at its characteristics.

Polycarbonate is a polymer plastic that has a monolithic, and more often cellular or honeycomb structure.

Polycarbonate is produced in thicknesses of 4, 6, 8, 10 and 16 mm.

For canopies in private households, material with a thickness of 8-10 mm is most often used.

There is also thicker polycarbonate with a thickness of 20, 25 and 32 mm, but this is used primarily for industrial purposes.

The standard length of polycarbonate sheets is 6 or 12 meters.

Standard width is 210 mm.

Cellular polycarbonate has been known for decades, but still looks impressive and modern. Moreover, it comes in different colors, of which there are about ten.

The advantage of polycarbonate over other materials is that it allows the production of arched canopies and other, more complex shapes.

Another quality that is unique to polycarbonate is its light transmittance.

Depending on the thickness and color of the material, it is 35-98%.

True, this quality can also be a disadvantage if you live in the southern region and do not want the canopy to get too hot in the sun. In this case, you should choose the color of polycarbonate that is less translucent. Bronze-colored polycarbonate has the lowest light transmission.

But when choosing a color, keep in mind that colors such as green and blue will make your face not very pleasant to look at under the canopy. Unless of course it has any meaning to you.

The next advantage of polycarbonate is that it is lightweight and can be installed even by one person.

Another positive quality is that it is not “noisy” when it rains, unlike a metal coating.

The price of polycarbonate is quite affordable and depends mainly on the thickness of the sheet.

Above I cited the positive properties of polycarbonate as a material for making awnings in the yard. Now let's talk about his not so strong sides.

The load-bearing capacity of polycarbonate is lower than that of corrugated sheets, so to ensure the required rigidity and strength of the coating, it will be necessary to make a frame with a large number of ribs. This requires more material, usually profile pipe. And the amount of work is increasing.

The service life of polycarbonate is 10-15 years, which is half that of a metal profile.

Cellular polycarbonate fades over time in the sun. Its color becomes a little faded. Although high-quality polycarbonate has an ultraviolet coating.

It is advisable to seal the ends of polycarbonate sheets using any available method. Otherwise, water entering the honeycombs in the fall at sub-zero temperatures can destroy the material, leading to cracks.

Well, I indicated above that good light transmission of the material can be both an advantage and a disadvantage. If the canopy is not well ventilated in the summer, it will be stuffy under it.

We briefly examined the performance characteristics of a canopy made of cellular polycarbonate. Now I propose to look at several examples of ready-made polycarbonate canopies.

Briefly about the main thing

Before designing how to make a cellar in a private house on the street, evaluate the construction conditions. The quality and moisture of the soil should be

The basement must meet all needs. Think about the entrance to underground storage, temperature and humidity control, and the number of shelves and drawers for food.

When building a basement, special attention should be paid to waterproofing and ventilation. Proper design of how to build a basement is already half the success of the undertaking.

Source of the article: https://blog.brigada174.ru/kak-sdelat-pogreb-v-chastnom-dome-na-ulice-tehnologija-stroitelstva/

Examples of polycarbonate canopies

In this selection of awnings, I tried to show you different options. Both for wealthy people with expensive houses, and for more modest buildings. Perhaps something will be useful to you as an example.

Cellar construction technology

Any construction should begin with a drawing. A diagram showing how to build a cellar can be found on the Internet. It is worth selecting only those drawings that correspond to the selected material.

Before starting construction, you should find out how to properly build a cellar, since it is better to resolve all difficult situations at the planning stage.

Canopy in the courtyard of a private house made of metal profiles: advantages and disadvantages

The second most popular material for making awnings in the yard is metal profiles or corrugated sheets, if that name is more familiar to you.

According to its purpose, corrugated sheeting is produced as wall, roofing, load-bearing and universal.

For our case, that is, for making a canopy in the yard, the optimal brands will be C20, C20K, C21, NS35 and MP. Corrugated sheeting of other brands, such as NS44, H57, H60 and H75, has a higher wavelength and is intended mainly for apartment buildings and industrial construction.

Galvanized corrugated sheets are produced in standard sheets 6 and 12 meters long.

Many manufacturers cut corrugated sheets with decorative coatings from 1.0 m in order to expand the range.

The width of metal profiles of different brands may vary. For painted ones it is 1100 mm.

Let's take a closer look at the performance characteristics of this material. As with polycarbonate, let's start with the positive qualities of the material.

An important advantage of corrugated sheeting is its higher durability. Its average service life is about 30 years, which is quite acceptable in most cases.

In addition, corrugated sheeting can withstand significantly greater loads compared to polycarbonate. If you live in a region where there is significant snow cover in winter, then this quality is essential.

The higher rigidity and strength of corrugated sheeting makes it possible to produce a canopy frame with a much smaller number of sheathing ribs compared to polycarbonate. This saves both money and time.

Laying corrugated sheets is very simple and does not require special skills.

The light weight of the sheets allows even one person to do the job.

Corrugated sheeting with decorative coating has a fairly large selection of colors, so you can easily choose what best suits the color of your house roof or fence.

A canopy made of corrugated sheets heats up significantly in the sun, but since it is not translucent, it creates a shadow. Therefore, under such a canopy it is not as hot as under a polycarbonate canopy.

The price per square meter of corrugated sheeting is slightly lower than that of polycarbonate.

The coating on corrugated sheets practically does not fade. In any case, it is not noticeable.

In what way does corrugated sheeting lose to polycarbonate?

Firstly, the corrugated sheeting makes noise in the rain.

But the main thing is that it does not allow you to build canopies of complex shapes. To lay corrugated sheeting, only a flat surface is required. For this reason, it is difficult to build something original.

Of course, you can lay corrugated sheeting in a wave along the decking, and not across it, as it should be. Then it can be bent in the same way as polycarbonate. Although this is not entirely correct from the point of view of organizing drains, if the shed is adjacent to the house. Yes, and you can use corrugated sheeting in this way only with a small comb.

Still, let's look at a few examples of canopies using corrugated sheets.

Homemade all-weather table for playing table tennis. Two design options.

Diary entry created by user Leo060147, 12/23/18 .130,

I like to play table tennis (hereinafter abbreviated as NT). And I play it regularly all year round. I play in the gym, sometimes I go to competitions in other cities. This is despite his rather advanced age. That is, I understand what kind of game this is, I understand the requirements for inventory. I enjoy the game. And when, in a conversation with one forum member who had built himself a country house for seasonal residence, his desire to put a tennis table on his summer cottage was voiced, and he asked the question which tennis table is best for his own plot of land, this question made me think. The standard table size is 2.74 m long x 1.525 m wide x 0.76 m high. The minimum size of a table tennis court according to SP

31-112-2004 Physical education and sports halls is 7700 mm in length and 4250 mm in width. See table. I would not recommend reducing these sizes. Especially in length. True, these dimensions apply to closed halls and probably for an open area the dimensions can be reduced. To what extent and how, this is a question more for those table tennis lovers who will play table tennis on their site. Next comes the question of where and how to place the table. The table can be placed outdoors or indoors. The best option is, of course, an enclosed pavilion, where you can play at any time, regardless of the presence of wind, rain, or snow. Indoors, you can place a regular, non-moisture-resistant table tennis table. In an open area, play will be hampered by wind, rain and snow. Even a slight breeze in an open area with a roof will not allow you to play NT. The ball (as the ball for playing NT is correctly called) is made of plastic, has a diameter of 40 mm and a weight of 2.7 grams. And it reacts very strongly even to a small breeze. But building a closed pavilion for the game, as the forum member https://www.forumhouse.ru/threads/370393/ did, requires certain investments, and you want to be able to play NT even in the absence of a special room. The most important thing is to have an NT table for playing. And here the painful choice begins. Which table to choose, how much does such a table cost, where to buy?

Since the table will be standing outside (at least for the first time), then its tabletop should be moisture resistant and should not deteriorate if moisture suddenly gets on it. The tabletop stand must be strong and stable enough. Tables with such a tabletop are called all-weather.

Most often, the tops of all-weather factory tables are made of melamine or similar plastics. In order not to clutter the topic with explanations of the difference between a regular table for playing indoors (indoors) and outdoors, I provide a link to a video where this is popularly explained.

Source

Options for canopies made of metal profiles

I said above that laying corrugated board requires a flat surface, but some interesting options are possible even in this case. So maybe this will suit your situation better.

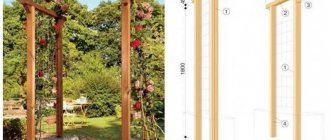

Arrangement of racks and rafters

One of the important stages in the construction of wooden canopies for a house is the choice of construction material. Any option will do, but try to use pine if possible. The wood for this type of construction is distinguished by good durability, low weight and pleasant appearance.

A cross-section of 75x75 mm or more is recommended. The material is carefully inspected to ensure that there is no bark. The part installed in the ground is covered with agents that prevent rotting. The main rule during installation is to maintain the placement parameters of about 100 cm between the pillars and arrange them in a certain order so that the roof in the side parts has 50-100 mm of protrusion, and in the front - up to 200. Half-meter wells are prepared along the general straight line while simultaneously checking the hanging diagonals. A level is used to maintain the strict verticality of the racks. For reliable fixation, auxiliary bars are used. After completion of the work, these elements can be easily removed.

The internal space of the recesses when constructing canopies for a summer cottage made of wood is filled with concrete mortar or crushed stone. The method of using crushed stone looks more economical.

Trimming with a bevel according to the angle of inclination of the plane is done in the upper part of the pillars. This will allow the rafters to lie tightly on the ends of the beam.

You can get an ideal horizontal line using a chop cord or a hydraulic level.

The minimum height of the racks at the bottom of the slope is 1800 mm. Below this parameter is allowed when planning in this part of the rack or table.

150x50 mm beams, called rafters, are needed for installing the system. The indicated dimensions are optimal for a span with parameters of 6 meters, if the design weight and slope of the canopy adjacent to the house are correctly calculated.

The spacing between the rafters is 1 meter. You can attach the canopy to the wall or support board with one side of the rafters, and the other rests on the posts. For fixation, self-tapping screws or steel angles are used.

Alternative canopy materials

We looked at two materials that are the most popular when building sheds in the yard. This is cellular polycarbonate and metal profile.

Is there an alternative to these materials?

Yes, there is, but not always the best.

The most worthy replacement for a metal profile would be metal tiles.

Its service life is just as long. And in general, in terms of technical parameters, it is close to a metal profile. And it even has some advantages. First of all, it looks more attractive on the roof than a metal profile.

The rigidity of metal tiles is slightly higher than that of metal profiles.

The snow moves off it less. This is important if you don't want it to fall on your head. But this only applies to flat canopies.

In this case, snow retainers are installed on the metal profile.

But in some ways, metal tiles are inferior to metal profiles.

Firstly, it is more troublesome to lay it. Although the work is not too difficult.

It is necessary to install transverse veins strictly at a certain distance from each other, since the metal tiles are not attached arbitrarily, but only in the recesses below the ridge.

Metal tiles are somewhat more expensive than corrugated sheets.

In general, this is a good option for building a canopy in the yard.

Are there any other options?

There are, but they are worse than the previous ones in terms of performance properties.

One of them is ondulin. Essentially the same slate, only produced using imported technology and painted in different colors.

It is lighter than domestic slate and is environmentally friendly.

This material is easy to install.

It has a reasonable price.

But ondulin also has disadvantages.

Its service life is 10-12 years.

Its paint fades and fades quite quickly.

It cannot withstand heavy snow loads compared to metal coating.

And most importantly, ondulin is flammable.

Another roofing material is the so-called soft roofing or soft tiles, as it is also called.

The ancestor of soft roofing is roofing felt. True, the performance characteristics of the new material have become significantly higher.

I will not dwell on this roofing material in great detail, but will only indicate its positive properties and disadvantages.

The advantages of this roofing material can be considered the following:

- original appearance of the roof;

- quick installation with a certain skill;

- sufficient choice of colors and shape options;

- suitable for roofs of complex shapes;

- has low weight;

- fireproof, unlike roofing felt.

The following qualities can be considered disadvantages:

- the price is higher than that of corrugated sheets or metal tiles;

- a continuous covering of boards or plywood is required, and a soft roof is laid on it;

- between the base of the roof and the soft roof, a special substrate must be laid;

- the material is not suitable for roofs with a slope of less than 12 degrees.

As you can see, there are not very many shortcomings, but they are serious. Therefore, it is worth considering before choosing this option for building a shed.

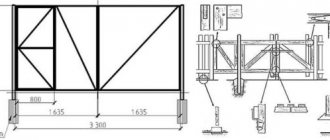

Installation work

How to properly make a canopy for your house with your own hands and get the desired result in a short time? The solution to this problem is achieved by strictly observing the sequence of all stages of the production process:

- A beautiful canopy for a wall always begins with a simple but very important process - marking for future supporting components and checking the identity of the distances between opposite corners of the perimeter, checking the required dimensions. Taking into account the selected dimensions of the pipes, we dig holes under the supports. The dimensions of the holes are one and a half bayonet widths and 0.6-0.9 meters deep. To ensure water drainage from the roof, we calculate the slope with parameters of 10 cm per linear meter of the roof. For our option, we plan the upper racks to be 3.3 m long, and the lower ones will be 2.7 m long.

- Square flanges are welded onto the supporting elements of the canopies near the house. A support element at the bottom and a platform for welding plugs and rafter components at the top will provide protection against subsidence. In addition, plugs on the 80x40x2 pipe will prevent the appearance of internal rust. Cleaned and primed areas of welding application are coated with paint.

- Before installation, check the dimensions and fill the supporting units with cement mortar. After giving the material a day to harden, we lay 80x40 mm rafter pipes. In this case, welding requires a slight exit beyond the perimeter of the rack.

- How to further build a canopy for the house using only your own strength? First, you need to lay out the entire board and slate so that the sheet at the bottom has an outlet of roofing material within 150-200 mm, and each lower roofing element overlaps the upper one by 100-120 mm. We cut the issue of boards on the sides to the same length, approximately 5-15 cm. After this, we calculate, not forgetting the need to overlap one wave, the length of the slate row. Connecting boards using nailing and subsequent welding on the inside remains the most affordable option. You can attach the board with self-tapping screws. A hole is drilled at the connection point and a countersunk hole is made for screwing.

Sergey Yurievich

Construction of houses, extensions, terraces and verandas.

Ask a Question

You can attach the board with self-tapping screws. A hole is drilled at the connection point and a countersunk hole is made for screwing.

Polycarbonate carport at the dacha: the best options

It may be necessary to build a canopy not only in the courtyard, but also in the country house. For example, in order to protect the car from direct sunlight and other unfavorable factors.

For example, let's look at canopy options using polycarbonate.

There is no point in describing the technical characteristics of this material for the reason that they were discussed above.

It must be said that a carport in a country house is not fundamentally different from a carport built in a courtyard on a personal plot. The only difference may be that it may be more modest if you do not have a luxurious dacha. And therefore less expensive. Both financially and in terms of labor costs.

It is not necessary to build such a canopy on a concrete foundation. It is enough to dig metal posts into the ground.

You can generally install the canopy on a metal frame and then it can be moved if necessary. Of course, it won't be very easy, but four men can handle it.

Of course, you can make a carport not only from polycarbonate. Corrugated sheets or metal tiles are quite suitable for this. It's up to you to decide.

By the way, in many cities such canopies can be purchased ready-made, as in the photo below.

Positive effects of tennis on human health

It has long been proven that tennis develops the body and spirit of a person. This sport is recommended by doctors for both young children and elderly people. In the process of playing without grueling exercises, muscles develop comprehensively, the eye, reaction speed and dexterity of the athlete improves. There are no small benefits from playing table tennis (ping pong) - for the heart, blood circulation and lung development, since such gameplay is an excellent preventive measure for the cardiovascular and respiratory systems.

Playing with friends and family in the fresh air relieves stress, eliminates depression and helps keep the body cheerful and toned. Moreover, this sport has virtually no contraindications for health reasons.

compensation for damage in the event of a fire in a private home

Drawing conclusions

The purpose of this article was to answer the question of what is best to make a canopy in the yard near the house or in the country. I tried to describe the advantages and disadvantages of most popular roofing materials. And you will have to draw a conclusion about which one to give preference to. For the reasons that it will depend on your financial capabilities and preferences.

But in any case, I approve of your desire to make your life more comfortable and wish you good luck in this.

Sincerely, Tkachenko Alexander.

Video description

Video tutorial on waterproofing a cellar:

Ladder

When making a staircase to the basement, it is necessary to understand that it will not only be used to ascend and descend into the cellar, but also to carry out vegetables, fruits, and canned food. Therefore, it is important to calculate the parameters of the steps. Recommended height: no more than 200 millimeters.

The design of the stairwell depends entirely on the type of basement. In underground rooms with a horizontal hatch, a staircase without risers is installed. Preferred material: wood or metal. The angle of inclination is 60-70 degrees, so it is also worth providing a railing.

For basements with a vestibule, it is better to make stairs from more durable materials: concrete, brick, cinder blocks. Leveled soil is used for the foundation of the structure. Railings are installed upon request.

Overlap

The ceiling is made of the following materials:

- wood;

- reinforced concrete or metal slabs;

- concrete filling.

Wooden floors, due to the material’s tendency to rot, have practically fallen out of use. However, if the construction of the floor is still carried out with wooden structures, then before laying it is necessary to clean the material from bark residues and waterproof it with bitumen coating or sheets of roofing material.

Varieties depending on functional purpose

Canopies can perform various functions, which allows us to distinguish the following types:

- Decorative buildings are used as an addition to the overall ensemble of buildings and landscape. Most often, in this case, they build a canopy with a pitched roof made of wood.

- Protective canopies prevent precipitation and ultraviolet rays from reaching the load-bearing walls of the house, preventing their destruction and extending their service life.

In some cases, single-slope awnings can be used both for protection and as part of the landscape.

Features of corrugated sheets

Corrugated sheeting is a material for the manufacture of which galvanized steel sheets with a thickness of 0.5-1.2 mm are used.

The use of corrugated sheeting as a roofing material for single-pitched metal canopies provides the following advantages:

- The canopy will be durable, resistant to moisture, ultraviolet radiation and mechanical stress.

- The work of covering the canopy will be completed as quickly as possible without any particular difficulties.

- The material is lightweight, which allows minimizing the cost of lathing.

- The reasonable price of corrugated sheeting will also help you save money.

The material also has disadvantages. Firstly, poor thermal insulation characteristics, secondly, low sound insulation, thirdly, not very attractive appearance.