Photo: 2gis.ru A good and reliable fence around the site requires the same gate. Of all the variety of materials, it is easiest to work with corrugated sheeting, because besides it you only need a few pipes, fittings and fasteners. Moreover, you can definitely do it with your own hands. Let's tell you more!

Advantages of gates made of corrugated sheets

Installing gates made of corrugated sheets has a number of positive qualities:

- The fence turns out to be durable. It is able to withstand any load, including strong gusts of wind;

- The fence is not subject to corrosion when exposed to moisture. Modern production methods make it possible to coat the metal with a special composition, which protects it from rust;

- Installing the gate will not be difficult because the material is lightweight;

- At a relatively low price compared to other types of materials, profiled sheets also have a decent appearance. In addition, the expanded color range allows you to choose the color to suit your taste.

Color variety

According to the method of applying the paint layer, sheets are divided into those painted on one side only, painted on both sides in the same shade, and multi-colored on both sides. The color scheme used is regulated by regulatory documents, among which the following standards are the most common:

- European (RAL);

- Finnish (RR);

- English (HPS);

- Swedish (PRELA).

For the construction of a fence, the most acceptable is corrugated sheeting that has double-sided painting. When choosing a suitable color, pay attention to its compliance with the overall design of the site and the house. Most often, preference is given to a green tint. It fits well into almost any landscape design and looks great against the backdrop of natural green spaces.

Brown, blue, and gray tones are also in demand. They are compatible with most building materials used for fences and building facades. It is not advisable to choose red and yellow colors. The worst solution would be to use unpainted galvanized corrugated sheet. It is not only unattractive in appearance, but also less durable and practical.

Types of structures

There are two types of gates you can make from corrugated sheets yourself: swing gates and sliding gates.

Swing gates consist of two doors that swing open in different directions from each other. With this type of gate, the load on the supports remains minimal. With this type of construction, the gate is mounted separately or located in one of the parts of the gate.

Sliding gates made of corrugated sheets are a single sheet that opens by rolling to one side. You can make either an automatic mechanism that will roll back the gate, or leave a manual opening method.

Sliding gates, unlike swing gates, require much less space. There is no need to leave it in order to open the doors of the structure.

But with sliding gates, it is worth strengthening the strength of the support, because the load in this system is distributed unevenly.

Before installation

We determine the dimensions of the future gate. Experts consider a meter wide opening to be optimal. A smaller size will create problems when bringing large items into the site. Large width increases the load on hinges and supports, thereby reducing their service life.

The passage and the fence should be the same in height - this will visually give integrity to the entire fence.

Gate size

Usually swing gates are made in such a way that a car can pass through them freely. Usually they take the width of the car and add a meter and a half to it, so that you can leave the site not only straight, but also turn.

It is also worth considering the size of the material itself in order to reduce the number of residues as much as possible.

Typically, the optimal gate width is from 4 to 4.5 meters, this distance also includes the width of the support. For a person to pass, you can leave 1-1.2 meters. This is quite enough to easily fit into the opening.

The standard length of corrugated sheeting is 2 meters; the height of the gate is determined from this indicator. The distance that remains from the ground level to the sash is also added to 2 meters.

It turns out that the height of such a fence is usually 2.1 meters. The space from the ground to the gate must be left at least 10 centimeters, because in winter, due to precipitation and the formation of ice, the gate may stop opening.

Difficulties in manufacturing sliding gates

Before you begin construction, you need to make a drawing of the gate. Particular attention should be paid to the drawings of sliding structures, because they are quite complex in execution.

You will face the following difficulties:

- Incorrect calculation of the counterweight can lead to the gate stopping opening;

- The foundation for the pillars must be strong, otherwise they may not withstand the weight of the structure;

- Welding elements of such gates will require certain skills and abilities. Without preparation it will be difficult to do this;

- If you plan to install an automatic mechanism for opening the structure, you will also have to tinker with it.

Swing gate design

If you have decided how to make a gate and have chosen a swing type, then the following description can serve as instructions for action:

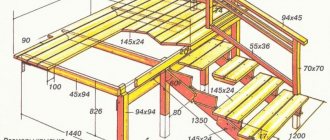

- First you need to draw up a drawing, indicating on it all the necessary dimensions. The simpler it is, the faster you can make the gate. Horizontal and vertical ribs are not needed for such a design, because the material itself is already quite rigid;

- The photo of a gate made of corrugated sheets shows that the frame is initially made. Corrugated sheeting can be attached directly to the frame, selecting rivets to match the material;

- The frame is made from a profile pipe. The section is selected individually. You can take either 60*40 mm or 40*20 mm;

- If the corrugated sheeting needs to be trimmed, you will need a grinder for this. Be sure to place the sheet with the front surface facing you, otherwise the edge will be uneven.

Unusual design for a gate

Wickets made of corrugated sheets with forging elements look very unusual, but at the same time chic.

Supplemented with forged parts, it acquires a unique look and immediately declares the high aesthetic taste of the owner.

An unprepared person will not be able to forge openwork elements on his own. They will have to be purchased at specialized stores. But it is quite possible to weld parts to the gate, turning the entrance door to the site into a real work of art.

Gate installation

In order to install a gate made of corrugated sheets, you will first need to make a frame.

- To do this, the pipe is cut at an angle of 45 degrees and welded with another pipe cut at exactly the same angle. The end result should be a frame rectangle.

- If you do not plan to attach the sheets directly to the frame, then you need to weld an additional strip onto the frame. You can leave it without it, then the fastening will be carried out directly to the frame.

- Next comes the installation of posts and hinges on the gate posts. There should not be too much of a gap between the post and the gate, maximum 3 mm.

- Now the frame needs to be fitted to the pillars. There is no need to rush to secure the structure; you should first check its correctness and the ease of opening and closing the doors.

- After this, a lock is placed on the frame, and the final stage will be painting the frame.

- This must be done, otherwise the iron will quickly rust. Before painting, be sure to clean the metal in the weld areas and sand the surface, if necessary.

- After the paint has completely dried, you can begin attaching the corrugated sheeting to the frame.

Swing gates are simpler and easier to install. Sliding ones are more difficult to make and it is best to contact specialists so that you do not have to redo the work.

Materials for creation

At the initial stage of work, sketches are made with the exact dimensions of the future gate. Based on them, taking into account the dimensions of the profiled sheet, the required amount of material is calculated. For further work you will need material for support. The height of the post depends on the design of the gate. 1 additional meter of height must be dug into the ground for reliability. For work you will need corrugated sheeting, a pipe for the frame, and metal processing products. As well as forging elements, the installation of which will be carried out by welding or screwing.