Stylish sliding gates

Sliding gates are the most convenient and popular type of gate

Sliding gates in high-tech style

Despite the fact that it is much more difficult to make sliding gates with your own hands than the more usual swing gates, and they are more expensive, an increasing number of country property owners choose them to organize the entrance to the site. Their important advantage is that they save space; there is no need to create a platform in front of the gate for opening the doors, which means that space can be used more efficiently, especially in a small area.

Today, sliding gates are at the peak of popularity

Sliding gates are very reliable, convenient and durable

In addition, there is no need to clear this area after a snowfall in order to open the gate leaves. Sliding gates are more reliable, they have better burglar resistance and wind resistance. And one more important plus - sliding gates with an electric drive are much easier to install; the automation for them is simpler in design, cheaper and more reliable.

Forged sliding gates

Advantages and disadvantages

The positive features of roller gates include:

- Compactness. They do not take up much space, allowing for free movement of transport.

- The bottom-mounted cantilever system ensures reliability and ease of installation in any weather.

- The opportunity to express yourself as a creative person when finishing is a rich assortment of materials. You can finish the gate with corrugated sheets or forging.

- Wide range of variations.

- Long time of use.

- Application of automated systems.

Sliding gates also have some disadvantages. Let's list them:

- To install this option you will have to spend more money than when installing other gates.

- The cantilever part requires the creation of a foundation for its installation.

- Despite the significant savings in free space in general, additional space is needed for the retractable part.

Sliding gates: main types

There are three types of sliding gates. We will consider the design features, their advantages and disadvantages below.

Sliding gates can be either automatic or manually operated

Beautiful sliding gates will highlight the style of your property

Types of designs

The current stage of development of society is characterized by an abundance of different forms and designs. The same applies to sliding gates.

One of the variations is hanging. This modification has existed for a long time and is characterized by high reliability.

The essence of hanging gates is that the material on wheels is attached to beams located at a height of about five meters. That is, a kind of height limitation for cars is formed.

Option with console. As mentioned earlier, the variation is resistant to weather conditions such as snow, gusts of wind, and so on. Cantilever doors do not place any limits on the height of machines. The structure requires the construction of a foundation for stability.

Modification of gates based on screw piles. Metal piles about 1.5 meters long are placed in the ground and act as load-bearing piles. As a rule, they are manufactured and installed in a short time - 3 days.

Mechanical design - requires manual opening and closing. The undoubted advantages of the variation will be easy installation and low costs. A good option for installation in a place that is not often visited.

Automatic gates are the most convenient option for regular use.

Another interesting option is a gate with a wicket.

Making a section with your own hands

The principle of manufacturing a sliding gate frame is the same as for swing gates.

Fundamental differences:

- one section is made;

- the frame must be light and have stiffening ribs.

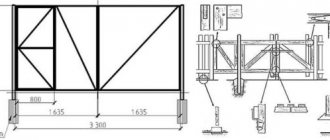

For a passage 4 meters wide, a section two meters longer is made. In our case, it will be a frame 6 meters long on the bottom side and 4 meters long on the top.

The result should be a design in the form of a rectangle in combination with a triangle (in one of the parts of the gate), that is, a trapezoid.

For structural rigidity, we reinforce the frame with profile pipes in the form of a mesh and a cross. We will separately consider the possibility of installing a gate in sliding gates.

She may be:

- free-standing;

- built into the gate.

The question of the type of gate should be decided during the manufacturing process of the gate frame - whether to embed it into the leaf. For sliding gates, experts advise making a free-standing gate and purchasing it in a factory version.

This will save you from many problems, since you will receive a complete package:

- drive unit;

- closer;

- lock;

- handle.

If you decide to embed a gate into the gate, we advise you not to place it in the center of the section, but to move it one meter from the edge. The width of the gate, as a rule, does not exceed 100 centimeters. The frame for the gate should be welded separately into the frame.

The hinges are welded in such a way that the gate opens inward without interfering with the sliding of the gate. The door should be equipped with high-quality handles and a lock.

Such a gate will cost you much less than a free-standing one. One of the disadvantages of a mortise gate is that it weakens the gate structure and the presence of a threshold. After this, thoroughly clean the frame from rust and scale, prime and paint thoroughly.

How to make a gate from a profiled sheet with your own hands? Read our article about this.

You can see how to make automatic gates with your own hands in this article.

What does the structure consist of?

Sliding gates contain the following parts necessary for installing the gate:

New Year in the yard: how to beautifully decorate the yard with your own hands!- How to make a modern landscape design with your own hands?

Microgreens at home

- guide beams that act as a load-bearing beam;

- roller supports;

- a roller that can be removed;

- windage and load regulators - catchers;

- a bracket is used as a fastening to protect the gate from swaying;

- a support that provides mobility to the doors and a stand for it.

Also an integral part of sliding gates on a cantilever basis is the foundation. Supports for the rollers are placed on it, and the load of the carrier is distributed on them. The rollers themselves are placed inside the console.

The doors themselves must also meet certain requirements. Such as stability, reliability in bad weather, strong winds, some rigidity. All these requirements ensure the functioning of the gate leaves.

The composition of the structure can be visually represented by a diagram of a sliding gate.

Foundation arrangement

The most important and time-consuming work is laying the foundation for securing the cantilever blocks, the structural part of the gate. The foundation is a rectangular block reinforced with metal.

It is installed from the inside of the fence, in the part of the opening where the door will roll back.

Important! Before starting excavation work, it is necessary to carefully calculate the dimensions of the foundation for the embedded element.

Foundation dimensions

- the length of the concrete rectangle is equal to half the width of the passage;

- width not less than 50 centimeters;

- the depth depends on the freezing of the soil plus 20 centimeters.

It is important to adhere to these exact dimensions so that your entire structure does not warp later - when the soil swells in spring, you simply will not be able to open the gate and get to your site.

We recommend making the width of the entrance opening 4 meters: an inexperienced driver will enter, and the truck will bring everything that needs to be brought. Therefore, the length of the foundation block will be two meters. The freezing depth in central Russia is about 140 centimeters. For reliability, we will deepen our block by 160 centimeters.

It is easier to make the foundation for the supports: dig holes for them to the same depth - 160 centimeters. Install the posts using a level and fill with concrete. There is a large amount of excavation work to be done - take equipment or friends to help.

In addition, it is necessary to level the area for the vehicle to enter on both sides of the gate. Remove fertile soil by 20 - 30 centimeters. Fill the area with sand and gravel, lay tiles or asphalt.

In this video you can watch instructions for making sliding gates with your own hands.

By ordering a corrugated fence with sliding gates, you will receive

When ordering the construction and installation of a corrugated fence with sliding gates from our company, you will receive a guarantee certificate that will confirm not only the quality of the work performed, but also our legal responsibility. Consequently, we will provide you with post-warranty service for the installed fencing for two years.

Order the construction of a fence from corrugated sheets with a 2-year guarantee

Methods for installing fence posts

Screwing in pillars

Installation of pillars for driving

Installation of pillars with concreting

Butting pillars with crushed stone

Learn more about pole installation methods

Why our company?

- Own production We have a production base equipped with uninterrupted equipment that guarantees high quality of finished products. In addition, in the process of work we use modern technologies that allow us to reduce the time it takes to complete orders.

- Full-time teams Absolutely all work on the construction and installation of corrugated fences with sliding gates is carried out by our full-time specialists who have many years of practical experience and professional skills. We do not hire outside workers.

- Discounts on installation Since we purchase raw materials in large volumes from regular suppliers at reduced prices, we have the opportunity to offer customers discounts on the installation of fences made of corrugated sheets with sliding gates of up to 30%, depending on the volume and level of complexity of the order.

- We do it thoughtfully and responsibly. Fast, but neat, smooth, beautiful.

Execution options

- Frame without covering

- Sheathing with corrugated sheets on one side

- Sheathing with double-sided corrugated sheet on one side

opening width 3500 (total door width 5000mm) 4300 (total door width 6000mm) opening height 2000 33200 34800 2500 33900 35200 opening width 3500 (total door width 5000mm) 4300 (total door width 6000mm) opening height 2000 39400 41000 2500 41400 42800 Profiled sheet Polyester, thickness – not less than 0.4, color – available from the manufacturer.

opening width 3500 (total door width 5000mm) 4300 (total door width 6000mm) opening height 2000 45500 47100 2500 48900 50300 Profiled sheet Polyester, thickness – not less than 0.4, color – available from the manufacturer.

Additional services

Repair and service

Measurement and production

Installation

Prices for repairs and adjustments

| Departure of a specialist within the ring road | 1400 rub. |

| Visit of a specialist in the area | 2500 rub. |

| Cost of 1 hour of work | 1500 rub. |

Gate repair tariffs

| Contract type | Price | Number of trips included in the price |

| Business | 36,000 rub. | 4 |

| Standard | 18,000 rub. | 2 |

| Economy | 9,000 rub. | 1 |