When landscaping the area near a country mansion or a summer cottage, it is important to install high-quality fencing, beautiful gates and a gate. The main thing is that the product is comfortable, reliable, and durable. The most suitable option is a metal gate. The main functions of metal gates and doors are to provide access to the yard, protect against unauthorized people and animals entering the area, and additionally decorate the area around the house.

Iron gate

A metal street door must match all buildings on the territory. If the building, for example, is lined with facade plasterboard or erected from wood, then a metal structure will be inappropriate; it is better to use wood for manufacturing.

Metal fences, gates, wickets are harmoniously combined with brick and concrete buildings.

How to build a gate yourself

Before starting construction, it is necessary to determine the exact dimensions of the future gate. Usually it is built at the same level as the fence and should not exceed a height of 2 m. If the fence is higher, then another transverse bar is added to its structure to strengthen the gate.

When designing the width of the gate, it is important to take into account the ability of not only the free passage of people, but also the ability to bring in furniture.A very wide gate will look bulky and will create additional stress on the fastening materials. Therefore, it is optimal to build a gate 1 m wide.

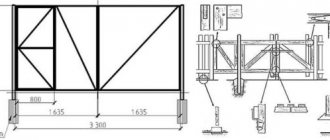

Wicket dimensions

To begin with, do not forget to prepare and later also look at the drawings of the gates when you design them with your own hands, so that all the dimensions match and there are no annoying surprises in the form of gaps, cracks or overlaps.

The height of the gate on external fences ranges from 2 to 1.2 meters. Gates delimiting the territory within the site can be made lower. And for solid fences, it is better to make the doors flush with the top of the fence.

The optimal width of the passage is 110-100 cm, but not narrower than 90 cm. Otherwise, passing through it will be problematic.

Set of tools for work

Many owners try to build a gate on their own. Before starting work, you should stock up on the necessary tools. For work you will need:

- measuring and marking tools;

- garden auger, shovel;

- welding machine;

- Bulgarian;

- screwdriver

- nails and screws;

- material for making the structure frame;

- equipment for making concrete mortar.

Drawing construction and material selection

You should decide in advance on the size of the gate and the material used. The drawing should not only indicate the dimensions of the future structure, but also provide for the location of individual elements in the form of inserts or gaps.

Wickets made of profiled metal can be combined with elements made of plastic or polycarbonate, and forged metal elements go well with wood.

The lock for the gate and the handle should be purchased in advance and their installation should be considered. After completing the drawing, you can begin to prepare materials for the construction of the gate.

Forged fencing options

According to their function and appearance, forged fences are conventionally divided into:

- protective;

- decorative;

- combined.

Most often, such protective fences are arranged in the shape of a peak.

They all look great, even the simplest designs. In terms of strength and inaccessibility, gates and fences made using forging techniques are not inferior to metal structures.

Protective fences include fences of any decorative complexity with a height of more than 1.5 m. They are installed on the border of the site, mainly on the front side - from the road. For the manufacture of most protective structures, simple sketches with a small number of decorative elements are used.

Installation of a fence to protect the facade

Decorative metal fences consist of a large number of artistic forging elements. They have different heights depending on their location. For example, you can fence off a recreation area from a garden with a beautiful, expensive fence 1 m high. Strength in such fences is of secondary importance, the main thing is the beauty of the forged figures and their combination. Decorative fences along the perimeter of the site are also protective.

Combined fencing includes several options:

- decorative and protective;

- with a high base;

- with a background fabric made of various materials.

Forged elements harmonize perfectly against the background of a solid metal sheet

They often combine sheets of corrugated sheets and bricks with decorative elements made by forging. The upper part of the fence is decorated with curls and peaks made from rods.

The disadvantages of openwork structures made from rods include their transparency. Through the openwork metal structures, not only sunlight and air freely penetrate, but also the views of strangers passing by, noise and dust from the street.

Openwork elements are most often used for internal fences

You can preserve the beauty of the lace sections and hide your privacy from prying eyes by installing opaque sheets on the inside or laying out a brick fence and decorating it with forged fragments. The canvases are made of various materials and cover the entire height of the fence or partially. The choice of material and the size of the canvas depend on the architectural style of the house and site.

Frame blank

The basis of a strong gate is the correctly selected material for the frame. Usually they take 4 beams and connect them into a frame. A crossbar is mounted in the center of the frame. The frame is tried on to the size of the span and only after that the hinges are hung and filled with sheathing material.

The structure can be strengthened by using reinforcing bars or metal corners. If desired, the gate is made blind, which firmly hides everything that is beyond its border.

Manufacturing procedure

The first step is to install the pillars (depending on the size of the sash, timber 60x60, 100x100 is taken), and the sash is made according to the size of the resulting gate opening. Standard sash dimensions are 1.1x2m.

Dig two holes 70 cm deep the width of a bayonet shovel. It is convenient to use a garden auger for these purposes. The screenings are poured into a 5 cm layer at the bottom of the hole. Then you need to prepare a wooden beam. Its lower buried part is burned with a blowtorch and treated with bitumen. Then it is placed in the hole on spacers and filled with concrete.

To limit the travel of the gate, slats are placed on the posts to imitate a quarter.

Scheme for installing columns in a bundle

Important! To achieve an ideal mutually parallel position of wooden poles, it is recommended to first knock them down crosswise with slats, thus assembling a rigid box. After this, they are installed in the pits in the form of such a structure and concreted. After the concrete has hardened, the slats are removed.

Assembling the gate on the frame

For assembly, prepare two identical horizontal beams along the width of the gate, onto which vertical slats will be placed. They are placed on a prepared table parallel to each other. It is advisable to make markings on the table and screw in the stubborn punks.

To maintain a constant gap between the vertical slats, prepare a thin rail, which is laid in front of each subsequent sheathing strip to be filled. The figured top edge of the picket fence is cut out with your own hands using a jigsaw after all the slats are nailed (or screwed). Therefore, it is not necessary to ensure that the top of the sheathing is level. The ends of the sheathing strips can be cut with a cone, and the edge of the slats can be processed with a figured cutter.

What does the assembled sash look like?

To attach the pickets, it is better to use stainless steel screw cutters. After the vertical strips are filled, the structure is turned over, the strut is measured and inserted.

Frame sash assembly

Making a wooden gate with your own hands is more difficult if you choose a frame structure. The complexity of the work depends on the design of the sash and whether it has curved lines. As a rule, the lower jumper of the frame and two side straight ones, and the upper jumper can be either straight or curved. The sash can be divided into 2 segments, with the lower part being solid and the upper part being transparent.

For the frame, a 30mm thick timber is taken, and the filler is made of 10mm thick lath and plywood. The essence of the design is that using a hand router, a groove is made with a 10 mm cutter on the inside of the jumpers. Slats or plywood will be inserted into it. If it is necessary to make a ledge less than 10 mm, then take a thicker lath (12 mm, 14 mm, etc.) and make the groove with a corresponding cutter.

Schematic diagram of the frame structure assembly

The vertical bars do not have to be cut to length; the excess ends can be trimmed off after assembly. And the transverse ones must be cut to length, since 3 cm spikes will be cut on them. If the width of the side post is 70 mm, then the length of the transverse will be 80 mm less than the width of the gate (140-60mm). The thorn is cut with a hacksaw, the cheeks are chopped off with a chisel. The eye in the rack is drilled out using a drill and finished with a chisel.

The infill lath (or plywood) is cut to exact size based on the depth of the groove.

Frame assembly process

The frame is assembled with glue, the tenons are reinforced with blind dowels. First, the lower jumper is connected to the stand, the filler is inserted, then the upper jumper is put on and the second stand is inserted. For tightening, use a hip or rope twists.

The simplest DIY design:

Choosing a location for the gate

It is usually installed together with the fence in the place that is most often used to enter the site.

If there is no need to install a gate at the entrance to the summer cottage, the most convenient place for the gate is selected. In this case, any type of swing gate can be built.To enter the territory of the site for motor transport, a gate is installed, where the gate can open as a separate door or gate leaf.

The most common and convenient option is to install a gate next to the fence, when, if desired, you can enter the territory of the dacha through the gate, and enter through the gate.

In this case, the wicket and gate are separated by a boundary post, which serves as a support for the structure.

Cheap or expensive gate?

Many garden lovers simply cannot imagine that any other material other than wood will appear in their space. Elements made from it (wooden gates or wickets) have long been valued by summer residents.

Swing gates go well with gazebos, houses, or, finally, with the above-mentioned vegetation. However, choosing cheap models is not necessarily a good option, it is better to invest a little more to enjoy high quality.

Therefore, you should choose durable, reliable and aesthetically pleasing wooden gates for your garden, which will delight owners for many years with their impeccable appearance and practicality.

Material for support posts

Metal or profile pipes with a diameter of up to 80 mm are often used as pillars. The wall thickness must be at least 4 cm. Pipe pillars are a reliable support for the structure.

Their light weight allows you to install them yourself in a short time. Sometimes stone or brick pillars are used. Their production is a longer process.

The disadvantage of the seemingly impressive support of such pillars is the tendency of the masonry to sag and collapse.

Important! To strengthen the structure of such pillars, a metal pipe is passed inside.

Gate supports

In order for the gate to stand level and not warp in the ground, it is necessary to install support pillars. For them, round hollow pipes or thick-walled profiles are used. The latter is more convenient, since a lock and hinges will be welded to the supports, but it is inconvenient to weld it to a round base.

For wooden doors, you can use wooden posts. However, you need to take into account that wood in the ground will sooner or later rot, and try to give preference to metal.

The question of how deep the pillars should be dug is resolved as follows: it all depends on the degree of freezing of the soil. Because of this feature, the soil “walks”, heaves in the spring, and the door can warp. To prevent this from happening, the supports are dug in below the freezing level of the soil by 15-20 cm.

The most durable and strong option is brick masonry pillars, to which a metal frame is attached, a frame for a gate.

Mounting and installation of the wicket frame

Before you start covering the frame, you should level the frame and try it on. To do this, the workpiece is inserted into the prepared opening and the gaps are aligned.

It is important not to forget to leave about 10 cm of free space at the bottom for the smooth opening of the gate. After hanging the loops, the workpiece is re-fitted and its movement is smooth.

Preparatory work

Preparations for creating a wooden gate begin before purchasing materials for it.

- The width of the passage and the height of the canvas are measured.

- The type of frame is determined.

- Drawings of the frame, panel covering and fastening diagrams are made.

- Beams, boards and fittings are purchased.

Creating a drawing is a mandatory step

The maximum width of a wooden swing gate is 1200 mm. The wide fabric turns out the fastening with its weight, so the hinges must be massive or 3 pairs. Experts advise making the canvas 1000 mm wide. This is enough to walk freely in warm outerwear. A garden gate for a seasonal dacha can have a width of 800 mm.

Variety of wickets

The choice of material from which the gate will be made should be approached carefully. The gate can be different in shape and material of manufacture. It can be decorated or left invisible to passersby.

Wooden gate

Every owner can make a wooden gate with their own hands. Such a structure has a number of positive qualities:

- use of environmentally friendly material;

- affordability;

- ease of purchase and delivery;

- ease of manufacture.

Among the negative qualities of wooden gates, they note the ease of breaking and short service life due to the inability of the material to withstand precipitation.

In order for the wooden structure to last longer, it is treated annually with special protective agents.

Frame for gate

The correct frame is very important for subsequent operation. This is the frame to which the door leaf made of wood or metal will be subsequently attached.

The most common frames are welded from metal profiles or corners. On this base you can attach any material you choose - corrugated boards, boards, polycarbonate sheets, slate, mesh, metal rods, complex forged patterns, etc.

The main thing is that the load-bearing capacity of the frame can withstand the weight of the entire assembled gate. Therefore, special importance is attached to its strength and wind resistance. Typically, a profile pipe with a cross section of 60X60 mm with walls 3 mm thick is used for the frame.

Gate made of profiled sheets

To make such a gate, a metal structure is first constructed from profiled pipes of the required dimensions, then it is filled with metal sheets.

There are several types of profiled flooring. Therefore, you should consider your choice in advance:

Sheets of the H series are distinguished by increased thickness and special stiffeners. A structure made from such sheets will be heavy and expensive, so it is better not to use them for a gate;

The ideal option would be to use sheets of the NS series. They are of medium thickness and are specially designed for use in the construction of fences and roofs.

Metal sheets of the C series have a small thickness. It can be used for construction of gates due to its attractive appearance. In this case, you should select a material with a thickness of at least 0.5 mm.

A gate with a fence made of corrugated sheets will reliably protect the area not only from prying eyes, but will also become a reliable defense against attempted vandalism. The disadvantages of using such a material are the susceptibility of the sheets to corrosion and simplicity of appearance.

Additional items

To reliably protect the site, owners prefer to install a lock on the street metal door. When installing a locking device, you should take into account the properties of the structure located on the street. The metal sheet is constantly exposed to heavy loads and negative environmental influences.

Electromagnetic lock

The mechanisms must be secured firmly so that they do not tear out under the influence of strong winds. Various types of locks are used:

- overhead;

- mortise;

- mounted;

- rack and pinion

Intercom

Based on the type of mechanism, devices are divided into types:

- cylinder;

- level;

- electromechanical;

- electromagnetic.

Door latch

While it is easy to install hinged, overhead, and mortise locking devices, installing electronic or electromechanical mechanisms is much more difficult. They also require electricity supply.

Canopies and canopies

It would be a good idea to install a canopy over the metal gate. The visor will reliably protect not only the lock, but also the bell, video camera, and intercom from rain and snow. Thanks to the canopy, the service life of the entire metal structure will be extended, as it reliably protects against fading and rust.

Near a private house

In case of heavy snowfalls, the canopy for the gate will protect the space at the entrance from snow. You won't have to waste time and effort cleaning it up. The following materials are used to make the canopy:

- Glass. Heat-strengthened and hardened material is used for the two outer layers, and a polymer film is used for the inner layer.

- Polycarbonate. Monolithic or cellular polycarbonate is used.

- Metal. Metal canopies are made from stainless steel with galvanized iron or metal profile casing.

- Metal tiles. A popular material for making canopies.

Gate with door in the fence

Canopies are made arched, with one slope, two, domed, straight with a valance, awnings.

The photo shows an iron gate with a canopy.

Visor

Mesh wicket

Chain-link mesh is often used to make gates. Ideally, this gate fits a fence made of the same mesh. Typically, such a structure has the same height as the fence. The convenience of using the mesh lies in its inexpensive price and ease of processing.

It is important that with good care, such a gate will last a long time. However, a mesh gate has the disadvantages that the area is clearly visible, and the wire is easily cut and cannot serve as a barrier to intruders.

For the construction of a gate, a mesh coated with a special PVC coating measuring 50x50 mm with a wire diameter of no more than 2.5 mm is ideal.

The use of such material does not require additional processing, and the high anti-corrosion properties of the treated wire will allow the gate to serve for as long as possible.

Making and installing a gate with your own hands

To understand how to make a gate, you need to look at this question step by step. The creation of a wooden structure begins with the frame.

Frame sketch options

It can be metal, from a profile pipe. Such a strong base is needed when making a combined structure decorated with forging or metal elements. In all other cases, the base is made of wooden beams 20–40 mm thick and 80–100 mm wide.

Frame

There are main types of frames for wooden gates:

- frame;

- rack Z-shaped;

- arched;

- with a portal - a canopy over the entrance.

Components of the entrance group

Light slatted wooden structures are made for a summer cottage and placed in the garden fence. Capital strong doors require a rigid base in the form of a reinforced frame.

Frame frames

Frame frames are a rectangular frame with a lintel. The frame is assembled using metal brackets - a perforated strip bent at a right angle. The bars are cut to size and laid out on a flat area, as indicated in the drawing. Brackets are installed in the corners from the inside and screwed with self-tapping screws or bolts. The boards are laid on top and the fabric is sewn up.

Idea for creating a frame

Connection at the corners is possible using the tongue-and-groove principle, if the level of skill allows and a router is available.

To create a three-dimensional frame, slats are nailed along the front side of the canvas along the perimeter, or grooves are cut in the horizontal beams of the frame and boards are inserted into them. The frame with this base option is assembled without a top crossbar. It is placed on top of the ends of the boards and screwed after covering the base.

Drawing for creating a steel base

The frame frame serves as the basis for more complex types of gate designs: with arches, combined inserts, portals. It is strengthened with spacers and struts.

Slatted base

Fences separating a garden from a yard often use a Z-frame. Two horizontal beams with an inclined bridge (strut) do not always represent an independent part. They are fastened together with sheathing boards in the manufacture of lightweight garden structures.

Frame mounting procedure

To create a strong Z-shaped frame, the following operations are performed.

- Horizontal beams are cut to a length 5 cm less than the width of the opening.

- They are laid out to size on a flat surface.

- The brace is noticed after the fact. The ends of the plank are cut at an angle and screwed with long screws.

- The frame is covered with boards.

- Canopies are screwed onto the crossbars from the rear side. On the other edge, a latch or latch is attached to the upper horizontal bar.

Decorative canopies with shaped strips can be attached to the front side and decorate a wooden structure, as in the photo.

Exterior design option with decorative elements

Arched and carved products are complex in execution and require a high level of craftsmanship, as well as special electrical equipment. They are not suitable for amateurs.

Canvas

The planks are cut to size according to the drawing, taking into account the gap at the bottom. They are laid out on a frame with a gap or completely, as the design is intended. When the boards are of different lengths, the top is shaped. The actual width of the created gate is checked, the size is adjusted due to the gaps.

Scheme of cladding the entrance group with dry planed boards of class AB

For a solid canvas, the board is immediately ordered with the calculated width so that you do not have to trim the edge strip and there is no gap left between the post and the gate leaf. The boards are sewn with a gap of 1–2 mm, for thermal expansion, so that they do not warp, resting against each other with their ends. This does not affect privacy, since nothing is visible through the gaps. The video clearly demonstrates the ease of making a frame wooden gate.

Polycarbonate – a new generation material

This material appeared on the construction market recently, but has already managed to win the preferences of summer residents.

A gate made from this material has a refined and attractive appearance. It is easy to process and assemble, does not fade in the sun and has a high degree of wear resistance.However, despite all its attractiveness, there are negative aspects of its use:

- is destroyed by both high and low temperatures;

- does not tolerate mechanical stress;

- is not an environmentally friendly material.

Forged gate - the ideal choice

Hand-forged metal gates are often a real work of art. Such a gate will not stand next to a dilapidated fence.

Both the house itself and the fence around it must comply with the use of such material. The impressiveness of the forged gate and its unique appearance emphasize the sophistication of the choice of the owners.The positive aspects that highlight its effectiveness are:

- reliability and strength of the material;

- durability with proper care, which consists of regularly lubricating the hinges and painting the metal elements;

- the possibility of combining metal with wood, polycarbonate, stone;

- environmental friendliness.

Among the existing disadvantages, they include the high price and heavy weight of the structure. It is better to entrust the installation and installation of a gate made using the forging method to specialists.

Having a beautiful and reliable gate is the dream of every owner. You can bring it to life with your own hands. The instructions on how to make a gate, located on various construction sites, can help with this.

Ideas for a homemade gate

In private houses, the entrance to the site is the calling card of the house, its decoration and expresses the hospitable or closed character of the owners. Therefore, most often gates are made according to individual orders, or even owners prefer to do it themselves.

With some dexterity and construction skills, it is quite possible to make it unique, beautiful and durable. In this article you will find examples of such original crafts and many photos of gates made by yourself.

Photo of a garden gate

Total

Category: Fence and gates