As an advertisement

If for professional builders the importance of geotextiles is like an axiom: obvious, proven and undeniable, then private developers are not well enough aware of all the possibilities of this unique material. This picture does not always develop, but quite often. The use of geotextiles in private construction is not so uncommon (rather, on the contrary). But, unfortunately, this material is used quite rarely correctly and for its intended purpose.

It is very easy to make a mistake in choosing geotextiles. Therefore, very often, not only those who completely abandoned this material, but even those who were able to find use for it on their own personal plot have to regret missed opportunities. Paradox? Yes. But the explanation for such an intricate curiosity is very simple: geotextiles are not a finishing solution, which, if it does not correspond to the chosen style, can always be changed (if desired). This is the material that forms the basis, and if the geotextile was chosen incorrectly, then even the most expensive and high-quality material will bring nothing to the owner except costs and disappointments.

Avoiding superficial judgments, we will try to delve into the very essence of the problem. Let's find out, for example, why for the construction of an access road it is necessary to use Dornit geotextiles with a density of 350 g/m2, and not some other? Why is it undesirable to use this same material in the construction of drainage sewers? There are many questions, and so that the most important information is presented logically and consistently, let’s get acquainted with the types and features of the use of geotextiles.

General concept of geotextiles

By definition, geotextile is a special type of synthetic fabric that is manufactured using various technologies and has different physical characteristics. Manufacturing technology and material density are the key factors that determine the final purpose of the geosynthetic fabric. Geotextiles are used:

- in road construction:

- in private and industrial construction;

- in agriculture and even in medicine.

Nowadays, geotextiles are increasingly used in landscape design and private construction:

- Being part of drainage systems, geotextiles protect the perforation of underground pipes from clogging, and bulk materials from mixing with the soil and from spreading (thereby it extends the service life and increases the efficiency of drainage communications).

- The use of geotextiles during the construction of the foundation is an opportunity to provide additional reinforcement of the base. Strengthening the underlying layer (for example, sand bedding), protecting it from mixing with natural soil - all this helps to reduce the consumption of building materials and reduce construction shrinkage.

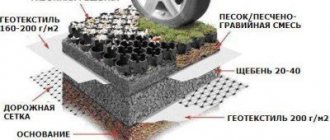

- During the construction of a roadway, geotextiles protect crushed stone from mixing with the soil, thereby allowing the thickness of the asphalt pavement to be reduced without losing its quality (the same functions are performed by geotextiles during the construction of pedestrian paths).

- It is completely impossible to imagine the improvement and decoration of a personal garden without geotextiles. It provides mechanical protection for film waterproofing used in the construction of reservoirs. Geotextiles also help protect decorative hills or landscape terraces from crumbling. Geosynthetic fabric increases the load-bearing capacity of the soil by an order of magnitude, and this quality is in demand wherever there is a need to strengthen bulk layers or protect materials susceptible to mechanical damage.

Advantages of using geotextiles in garden design

The use of geotextiles largely depends on its characteristics. The special technology for creating the material guarantees several advantages of the raw material:

- High level of environmental friendliness. The canvases do not decompose into chemical elements, so they do not harm human health or nature.

- Strength. Non-woven fabrics are resistant to deformation, mechanical flaws, piercing and tearing loads. This eliminates damage to the material during installation.

- Resistance to environmental factors. The canvases do not rot, do not rot, do not silt, they are very resistant to ultraviolet rays, various types of acids, alkalis, and substances of organic origin.

- Easy to install. The raw materials are sold in the form of small and light rolls, so they are extremely convenient for transportation and cutting with a knife or scissors.

- Low pricing policy. The material is an ideal ratio of price and quality, therefore it is actively used in industrial construction and for domestic needs.

The wide scope of operation makes the purpose and use of geotextiles a universal solution to many problems.

Raw materials for the production of geosynthetic fabric

Most often on sale you can find geotextiles made from polyester and polypropylene fibers. Thanks to its high strength and durability, polymer geotextiles have gained popularity in the construction industry and agriculture - where these qualities are valued most.

Less common are geotextiles made of fiberglass and various natural inclusions (textile industry waste: cotton, wool, etc.). The use of natural fillers somewhat limits the scope of application of the material. Such fabric, for example, is not recommended for use in the construction of drainage communications, since it quickly wears out, and this leads to clogging of drainage systems.

What is geotextile?

Geotextile is a material made from synthetic polyester or polypropylene fibers using a woven or non-woven method. High-quality geotextiles are distinguished by high performance qualities and a fairly long service life. The material is sold in rolls of different widths, which can vary from 2000 to 5500 mm, lengths from 10 to 150 meters, and can have different thicknesses and densities.

Geotextiles are produced in different designs, which differ from each other in their operational and physical and technical characteristics. But some qualities are common to all varieties of such products:

- The materials have fairly high elasticity.

- Geotextiles promote uniform distribution of load from bulk materials.

- The fabrics are resistant to chemical oxidative processes.

- The material perfectly prevents weeds from growing through the main coating.

- Properly laid geotextiles promote timely drainage and perform well as a filter.

- The materials have excellent reinforcing qualities.

- Such products are not susceptible to destruction by insects or rodents.

- Geotextiles are affordable and easy to use.

Polypropylene geotextile

Geo-fabric made of continuous polypropylene fibers is a material based on a thermoplastic polymer with increased chemical resistance. Polypropylene fibers are a product of the polymer industry, which is a primary, that is, unprocessed raw material. The use of solid fiber gives the fabric high strength, but when exposed to sunlight, polypropylene threads quickly lose their strength. This problem is fixable: by adding chemical stabilizers to the product that protect it from exposure to ultraviolet radiation, polypropylene geotextiles are successfully used in a wide variety of areas of human activity. The relatively high cost of polypropylene geotextile is a consequence of the technological features of production.

Working with material

When arranging a landscape using geotextile, first measurements are taken and markings are applied. Then sand, geotextile, and crushed stone are laid. Where there are joints, the sections are stitched or fastened with a construction stapler. The final stage is an external covering of tiles, gravel and other materials.

If a swimming pool or other artificial reservoir is to be installed, then heavy-duty options are used. The fabric is laid over the insulation and secured with stones if work is being done on the inner surface. Laying around the pond will protect against weeds and prevent the roots of trees and shrubs from sprouting, and will preserve the integrity of the structure.

Video review of geotextiles in flowerbed design:

Polyester Geotextile

Polyester geotextile is a material made from short polyester fibers. They are based on recycled materials (plastic waste, polymer production waste, etc.), which significantly reduces the cost of the canvas, but gives it sufficient strength.

A suitable example of quality, durability and practicality is Dornit brand polyester geotextiles with a density of 250 g/m² - a popular and economical solution for low-rise construction, landscape design and complex landscaping of homestead areas.

With this, the classification of geotextiles based on materials of manufacture can be completed. There are not so many options, and their differences are clear even to the uninitiated.

The situation with production technology is much more interesting, because the area of application of geotextiles depends on it.

Based on the manufacturing method, geotextiles are divided into two main types: woven and non-woven.

Rules for laying paths

When arranging garden paths at the dacha, it is recommended to follow the following stages of work:

- Markings are made across the entire area of the site where the path will be laid. Next, the soil is excavated and the bottom of the ditch is cleared of weeds, roots and other debris.

- The selected geotextiles are laid in one layer in prepared shallow trenches. Here it is important to ensure that its edges extend beyond the surface of the soil. At this stage, the material is leveled and all folds are removed from its surface. It is better to securely fasten different pieces of fabric to each other with a special stapler or thread.

- Next, a cushion of sand and crushed stone, about 15 cm thick, is laid and compacted tightly.

- A second layer of geofiber is laid on top, and sand is poured on top of it, which is recommended to be pre-moistened.

- The textiles protruding along the edges of the track are carefully trimmed.

- Next, you can begin laying the tiles.

Woven geotextile

Woven geotextiles (geofabric) are made using classical technology, which is based on the mutual interweaving of longitudinal and transverse fibers. This material has high tensile strength and can withstand breaking loads well. These qualities determine the area of application of geofabric:

- construction of reinforced earth embankments;

- arrangement of retaining fortifications;

- arrangement of foundations with complex configurations;

- road construction;

- complex construction work, construction of engineering infrastructure and so on.

Why do you need geotextiles when arranging garden paths?

When laying paths in the yard, various materials are used. But in any case, a sand and gravel cushion is built between the soil and the finishing coating. So that it does not sink into the ground, does not succumb to moisture, and so that voids do not form under it, it is necessary to use geofabric for garden paths.

Also, when using geotextiles, you can get rid of not only soil subsidence, but also the destruction of the finishing decorative coating. In addition to protection against deformation, it also has other functions:

- high moisture resistance. Thanks to this, melt and rain water does not linger at the base of the path, which prevents the process of erosion and has a good effect on the appearance of the coating;

- serves as a good barrier to prevent the growth of weeds and bush roots. The fabric prevents grass and roots from growing through the path, thanks to which it maintains its integrity.

Non-woven geotextile

Non-woven geotextiles, in turn, can be thermally bonded and needle-punched. In the first case, geotextile fibers are bonded together under the influence of high temperature, in the second - under the influence of a mechanical press with needles.

Thermally bonded geotextiles are made exclusively from polypropylene fibers. This determines its main qualities: strength and elasticity.

Thermally bonded geotextiles are successfully used to strengthen the soil during construction on slopes. Also, its qualities can hardly be overestimated if you are planting trees or improving plant areas (it retains moisture well, thereby allowing you to increase the intervals between watering plants by an order of magnitude). But due to the low filtration coefficient, this material should not be used in the construction of drainage communications, because it allows water to pass only in the transverse direction.

How agrofibre is laid at the dacha

Paths and parking

A dacha with sidewalk paths is a beautiful and comfortable dacha. Everyone who installs them wants them to last for years to come. But it often happens that the paths fail, sag, cracks appear on them and grass grows in the seams between the tiles. But if you use geotextiles when laying sidewalk paths or parking areas, such problems can be avoided.

Agrofibre should be laid under paving slabs as follows:

- Remove the soil to a depth of 30−50 cm. The depth depends on the planned load.

- Cover the geotextile so that it covers the bottom and walls with a protrusion of 10 centimeters above the future zero level of the site.

- Fill and level the crushed stone.

- Cover the second layer of geofiber. It is important to overlap at least 30 cm.

- Fill with a 10 cm layer of sand.

- Next, the paths are laid in the traditional way.

By adhering to this technology, you don’t have to worry about the quality of the coating. It will serve for many years without changes.

Garden

Agrofibre makes agricultural work easier. Now you won’t have to weed the garden bed. To do this, you need to adhere to the following algorithm.

- Cover the ground with cloth. It is important to overlap at least 25 cm. Otherwise, weeds may grow at the joints.

- Make holes in it at the required distance. For strawberries, for example, the step between the holes is 20-30 cm.

- Plant plants in the resulting slots.

The pores in the geofiber will allow moisture to pass through and provide the necessary air exchange. Loosening is also not required, since moisture will flow through the pores capillarily and the soil will not be compacted.

Flower beds

For flower beds, you need to remove the top layer of soil, fill the resulting ditch 5 cm with sand, cover the bottom and edges with geofiber with a small exit to the surface, install a drainage layer of crushed stone if necessary, and fill in the chernozem layer.

Needle-punched geotextiles are an indispensable solution for private construction

To produce needle-punched geofabric, both short and continuous polymer fibers are used. The mechanical method of fastening fibers simultaneously gives the fabric both strength and a high filtration coefficient. This significantly expands the scope of its application. Considering that modern technologies make it possible to produce material with specified density parameters, it is difficult to find a more suitable synthetic fabric for private construction than needle-punched polyester geotextiles.

Root containment

In some cases, gardeners need to restrain the growth of the root system of trees or shrubs. Geotextiles are perfect for these purposes; due to their high strength, they are able to prevent roots from spreading beyond their boundaries. To do this you need:

- Dig a hole in the place of the future plant.

- Cover it with geotextiles. It is important that there is a small amount of material left at the edges of the pit.

- Fill the resulting “pot” with soil.

- Plant a plant.

The note. It is worth noting that this method works both ways, so it is excellent not only for containing the root system, but also for protecting it from surrounding dangers, such as insects.

Density of geotextiles and areas of its application

For private construction, for work related to landscaping, as well as for the construction of temporary local roads, construction experts recommend using Dornit needle-punched polyester geotextiles, the density of which varies from 150 to 350 g/m².

On the one hand, this material is inexpensive, thanks to which the average private developer can purchase it without any problems, on the other hand, the characteristics of the material fully correspond to the listed areas of application. The Dornit classification by density has a step of 50 g/m², and each subsequent classifier step has its own narrowly targeted purpose.

To understand how to choose the right fabric based on density, let’s look at several examples of the intended use of needle-punched geotextiles.

Errors and problems when laying geotextiles

The most common mistakes that homestead owners make are:

- incorrectly selected geotextiles. Here it is important to take into account the type of soil, the level of groundwater, and climatic conditions;

- inappropriate trench depth. It should be no more than 40 cm;

- incorrectly selected similar materials. If for some reason it is not possible to use geofabric on the site, it can be replaced with the following analogues: roofing felt, metal mesh, doronite.

In conclusion, it is worth noting that the use of geofiber when laying paths in the yard requires special attention. Since this material can sag, deform and even rot (with abundant moisture). But with a competent approach to laying a garden path with geofabric, the paths will delight the owners with aesthetics, high technical characteristics, durability and resistance to negative factors.

Geotextile with a density of 150 g/m²

Geotextile "Dornit" 150 g/m² was developed specifically for the construction of drainage systems and for strengthening the soil when organizing drainage communications. The small pores of denser geotextiles quickly become clogged with solid microparticles of soil, thereby reducing the filtering capacity of the material. At the same time, the material, with a density of 150 g/m², is ideal for drainage and excellently strengthens weak foundations.

Comfortable garden

Using geotextiles for garden work it is very easy to create beautiful designs in the garden. You can organize a flower bed, make a rock garden, an alpine slide, or artificial terraces. You can make a real pool in the middle of the garden lawn without spoiling the green covering.

The geomaterial will strengthen the soil, the grass will not wrinkle underfoot. A sports ground and children's playground are organized in the same way.

The use of geotextiles will allow you to quickly create impeccable beds and flower beds. Do you want a symmetrical arrangement of trees on your site? Then, when laying the geotextile fabric in the appropriate order, make X-shaped cuts on the fabric and plant the seedlings in them. Geotextiles will protect tree roots from damage; weeds will not be able to grow through the layer of material, which will allow your garden to have a spectacular, impeccable appearance.

Geotextile with a density of 200 g/m²

Geotextile "Dornit" 200 g/m² is designed to strengthen unstable and weak soils. It is used in the following situations:

- when it is necessary to arrange a lawn on a personal plot: to stabilize the soil or protect the soil from deformation;

- when it is necessary to strengthen an unused embankment;

- during the construction of pedestrian paths and decorative slopes.

Most often, people who engage in landscape design use material with a density of 200 g/m². With its help, you can effectively separate layers of soil in unexploited areas or protect lawns from the germination of weeds.

The use of road geotextiles on your site

Since this material is actively used in road construction, a popular area is the use of geotextiles for garden paths. The canvases allow you to separate layers to reduce the level of load on the base of the structure. Also, such raw materials are an excellent solution if it is necessary to reinforce the soil, which is especially important when moisture levels are high.

When arranging garden paths, you can profitably use another property of the canvas - to prevent pressing of crushed stone, thereby guaranteeing a higher level of compaction. In addition, thanks to the use of raw materials, it will be possible to achieve the following results:

- reduce the cost of purchasing sand or crushed stone;

- reduce the time required for the construction process;

- reduce the cost of further maintenance of a parking lot or garden path.

Agrofibres are also actively used for the formation of open areas around the house and the formation of rocky gardens. Thanks to this material, it will be possible to create beautiful patio areas, divide and build various types of embankments, and strengthen surfaces. It is impossible to imagine the creation of children's playgrounds in suburban areas without the use of agrofibre.

Geotextile with a density of 250 g/m²

Needle-punched geotextiles with a density of 250 g/m² are chosen by those who plan to undertake large-scale construction work on their own personal plot. This material is optimal for strengthening the soil under the foundation by laying a sheet under a sand cushion. It reliably separates the shock-absorbing bedding from the main soil and allows you to evenly distribute the loads along the entire perimeter of the foundation. At the same time, Dornit 250 g/m² is successfully used to strengthen blind areas, as well as for mechanical protection of polymer film used in the construction of swimming pools and artificial reservoirs.

Advantages and disadvantages

The main advantages of using geotextiles when laying paths include:

- ability to withstand heavy loads;

- preventing paths from becoming overgrown with weeds by forming a barrier between the soil and the decorative coating;

- good protection from dirt, since sand will not mix with the soil;

- good soil strengthening on slopes;

- possibility of carrying out repair work;

- reliable protection from high humidity;

- the aesthetics of a path built even on difficult and depleted soil.

Also, to the advantages of using this material, it is worth adding that the paths do not lose their shape for a long time and do not allow water to pass through. And if paving slabs are laid on geotextiles, they last a long time and last well. In addition, geofabric is durable and easy to install. The installation process does not take much time, and even beginners can cope with this workflow.

Geotextile with a density of 350 g/m²

Needle-punched geosynthetic fabric, with a density of 350 g/m², has also become widespread in private construction. This material is most suitable for the construction of reliable access roads, car parks or massive foundations. It can also be used to solve other problems that have a similar purpose and corresponding level of complexity.

Brands and types of geotextile material

Geotextiles in gardening are selected based on the type of problem being solved. If it is necessary to use good filtration and hydraulic permeability of the layer, but with low strength, needle-punched geotextiles should be used. If strength is a priority in the landscape, thermally bonded materials are a worthy choice.

When choosing a brand of geomaterial, we pay attention to the type of soil, the thickness of the embankment layer, and especially the functions that the material should perform.

The main advantages of Dornit brand needle-punched geotextiles

The key advantages of the presented material lie in the almost unlimited scope of its application, as well as in the unchanged performance characteristics throughout the entire period of operation (which, by the way, reaches 25 years). It is characterized by:

- strength and durability, which are achieved by using non-degradable geosynthetic materials;

- resistance to vibrations and temperature changes;

- good filtering ability even under extreme operating conditions (intense vibrations, strong mechanical pressure, etc.);

- environmental friendliness and affordable cost.

By the way, about the cost: the price of the material includes all the costs that are required by impeccable adherence to production technology, the cost of purchasing high-quality raw materials, as well as the cost of operating high-tech production equipment. If you like geotextiles that are too low in price, it means that one or another cost item is not included in its cost. Consequently, the material was produced in violation of technology or using low-quality raw materials.

It is impossible to create high-quality material without appropriate investments, so cheap geotextiles will have neither reliability nor durability. By purchasing geosynthetic fabric from official dealers who directly cooperate with the manufacturer, you will always receive guaranteed quality at a reasonable and reasonable cost.

Subscribe to our Telegram channel Exclusive posts every week

Features of a track with a geotextile backing

A garden path equipped with geotextile fabrics will retain its configuration for a long time.

In this case, the crushed stone layer will be used as drainage, through which moisture will freely drain into the sand and soil. As a result, the layer is compacted, and the geotextile fabric ensures the unhindered removal of excess moisture.

Sand poured onto geotextiles acts as a cushion for decorative material laid out on the surface. If any tile product begins to sag, the path can be quickly and easily repaired. To do this, you just need to lift the settled element and sprinkle a little moistened sand under it, then compact it with a mallet.