Author of the article

Khvatkov Dmitry

Consultant in the field of rubber coating production

Crumb rubber flooring is a practical and multifunctional solution. This flooring is resistant to temperature changes, moisture, has good shock-absorbing ability and is highly wear-resistant. The wide range of colors and aesthetic appeal of the material make it possible to give the territory being developed a complete appearance. In the manufacture of rolled flooring, a UV-resistant coloring pigment is used, so the material retains its deep, rich color for a long time.

High-quality roll coating, subject to installation technology and operating rules, can withstand mechanical and vibration loads, and therefore can last more than 15 years. In this article we will talk in detail about how to glue rubber coating to different types of bases, what glue and tools will be needed for this.

Artificial Grass for Playground

This covering on the playground, football field, and recreation area successfully replaces a natural grass lawn. Its quality is so great that since 2005 FIFA has allowed matches to be played on artificial turf fields.

Making sports turf is similar to carpet weaving. The dense polymer canvas (base) is quilted with polyethylene threads (tufts of grass). The process is called tufting. Artificial grass carpet is sold in rolls.

A polyethylene lawn is not fertilized, watered or mowed, but maintenance is required. Weeds manage to grow through the artificial carpet and have to be removed. Many types of artificial grass are periodically sprinkled with quartz sand. This is how the playing properties of natural lawn are reproduced. Sand bedding is used when equipping high-quality playgrounds and sports fields.

Sports fields are covered with artificial grass Source sportcover.ru

Artificial turf in open areas is laid on crushed stone bases. It is possible to lay synthetic grass on sand; this option is not recommended for sports fields due to the instability of sandy soil. In some cases, the base for installation is concrete or asphalt.

The main requirement for a loose base is hygroscopicity. For concrete or asphalt, there must be a slight slope for water to drain. In addition to green, white synthetic grass is produced. Inserts are made from it - marking elements.

Sellers offer different types of artificial grass.

Based on the type of blades of grass, the coating is divided into:

- monofilamentous;

- fibrillated.

In the first case, a bunch of grass is obtained from one polyethylene strip. In the second, only the upper part of the strip is cut into conditional blades of grass. Monofilament coating is difficult to distinguish from natural. Fibrillated is cheaper and wear-resistant.

Artificial turf is visually indistinguishable from natural grass Source gazon360.ru

In relation to adding quartz sand, grass is:

- Non-backfilling . The length of the grass blades is from 4 to 10 mm. Used in low-use playgrounds or as a decorative element.

- Half-filled . The length of the grass blades is from 7 to 35 mm. It is preferably filled with quartz sand. The amount of sand introduced affects the hardness of the field. The less sand, the softer the field.

- Zasypnaya . The length of the grass blades is from 40 to 70 mm. It is filled with a mixture of sand and rubber granules. Used on professional football and rugby fields.

More often than synthetic turf, rubber surfaces are used on outdoor children's and sports grounds. They are cheaper than artificial grass, require almost no maintenance, and have “athletic” properties.

Installing tiles on a hard surface

The sequence of actions when installing the coating is as follows:

- The base is primed.

- The surface must dry for one hour.

- A cord is stretched around the perimeter of the base.

- Rubber-bitumen mastic is applied. Use a spatula or roller to level the adhesive layer.

- An area in the shape of a simple geometric figure suggests starting the installation of tiles, moving from the middle to the edge.

- Lay the tiles on the surface in dense rows with minimal gaps, and all elements must be pressed tightly to the base.

- After this, the remaining air under the coating is removed with a rubber hammer.

- A rubber curb is installed.

Two days after installation, the coating can be used.

Don’t be intimidated by the new material; installing rubber slabs will only require some effort, but it’s worth it, as a result you can get a beautiful, safe and reliable coating.

Crumb rubber is the main component of soft coverings

Crumb rubber is obtained from old car tires. They are sorted, the side rings are cut out, and crushed. Metal and tissue components are extracted from the resulting particles. At the final stage, the crumbs are divided into fractions ranging in size from 0.7 to 7 mm.

Crumb rubber from tires Source akmgk.ru

The crumb inherits the chemical composition from tires:

- Rubber. Typically this is a mixture that may contain natural rubber, styrene butadiene rubber, butadiene rubber and isoprene rubber.

- Carbon black. The common name is soot. It makes up a third of the volume of all the components from which tires are made.

- Silicic acid . Partially or completely replaces carbon black.

- Sulfur . Together with silicic acid it is a vulcanizing agent.

- Vulcanizing activators (stearic acids, zinc oxide).

- Other Supplements.

Crumb rubber is produced not only in the process of recycling car tires, but also directly from ethylene propylene rubber. This material is synthesized at chemical plants and is called EPDM or EPDM rubber. Available in the form of granules ranging in size from 1 to 4 mm. The elastomeric properties of crumb rubber obtained from recycling old tires or as a result of the synthesis of EPDM rubber are practically the same.

EPDM rubber granules Source www.olympicsports.kz

Preparing the mixture

The composition of the mixture is based on a covering area of 1 sq. m thickness 10 mm:

- crumb rubber – 8 kg;

- binder – polyurethane glue – 1.7 kg;

- coloring pigment of a certain color - 0.5 kg.

In practice, the optimal amount of mixture preparation at one time was established. This is the calculation of the ingredients required to cover 4 square meters. m.: 32 kg of crumbs, 6.8 kg of glue, 2 kg of dye.

The kneading is carried out for 10 minutes. First, mix the crumbs for about 2-3 minutes without adding other components to break up possible lumps formed as a result of caking. Then the pigment is added, which within 3 minutes will be evenly distributed throughout the entire volume of the crumb. Without stopping the mixer, add glue in a thin stream. After approximately 2-3 minutes it will mix evenly. The working mass is ready.

Helpful advice! Weigh the mixture ingredients as accurately as possible using an electronic scale. A deviation in the weight of the dye by even 50 grams will lead to the appearance of an undesirable distinctive shade.

Seamless rubber coating

This coating is called seamless, monolithic or self-leveling. To install it, crumb rubber and a binder are required. It can be multi-component, but more often one-component polyurethane glue is used. In screw or planetary mixers, a working mixture is obtained from crumbs and glue.

The technology for laying crumb rubber is similar to asphalt paving. In small areas, the working mixture is leveled manually, using rollers or hand rollers. When filling large areas, automated pavers are used.

Manual laying of seamless rubber coating Source 9ban.ru

Up to 4 cm of crumb rubber is applied to loose soil. It is enough to put 1 cm of the working mixture on leveled concrete or asphalt. In addition, the concrete is pre-primed with polyurethane glue. This increases the wear resistance of the coating.

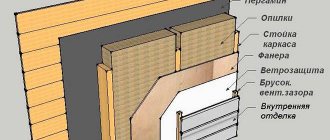

To obtain the highest quality coating, a two-layer “pie” is laid on the base. The bottom layer of the “pie” is coarse crumbs. Its thickness is 80-90% of the entire coating. The remaining 10-20% is occupied by the top layer, consisting of small crumbs with a granule size of 1 mm.

When filling critical areas, for example, athletics tracks, the top layer is applied by spraying. This technology increases the “athletic” properties of the rubber coating, but makes it more expensive.

Ethylene propylene rubber granules are produced in white, blue, green and other colors. Crumb rubber obtained from old tires is colored black due to the soot it contains. To give it a variety of colors, powder pigments are added to the working mixture before pouring. The multi-colored area pleases the eye, and the bright, contrasting markings help during competitions.

Colored crumbs made of ethylene propylene rubber Source www.intereco.ru

Seamless laying of rubber coating from crumb rubber is a technology that allows you to obtain the highest quality, safe, multi-color coating for a small playground and a large stadium.

Multi-color seamless coating on the playground Source tramplinsport.ru

See also: Catalog of companies that specialize in playgrounds, as well as landscape design and landscaping.

Advantages

The use of crumb rubber provides the following advantages to the coating created on its basis:

- Persistence. This material tolerates temperature fluctuations well, as well as any type of deformation and exposure to ultraviolet light.

- Wear resistance. Thanks to its special properties, this material is durable.

- Aesthetics. A wide variety of color solutions and their combinations allows the material and coatings made from it to look quite attractive. This is largely due to the ability to withstand fading and the effects of aggressive substances, including alkalis, acids and solvents.

- Hygiene. The coating created on the basis of crumb rubber demonstrates resistance to rot, mold, weeds and insects.

- Elasticity and safety. The absence of toxic emissions from this material makes it safe for humans. This is greatly facilitated by the presence of such properties as tram and impact resistance, as well as anti-slip.

- Easy to care for. Due to the absence of shrinkage and the presence of a seamless structure that does not allow grass to grow through the coating, it does not require special measures to maintain it in proper condition. Coverings located outdoors are quite easy to clean, and those located indoors can be kept clean with a vacuum cleaner. They are also repairable.

Rubber tiles

A tile is a product based on rubber crumbs. At the manufacturing plant, the crumbs are mixed with a binder and a dye is added. After that, rectangular rubber plates are formed by cold or hot pressing.

The common shape of the tile is a square with a side of 0.5 m. Its thickness varies from 1.6 to 4 cm. When pressed, a relief pattern is extruded on the upper surface. It gives the covering of playgrounds an attractive appearance and increases the anti-slip properties of the covering material.

Rubber tiles Source images.ru.prom.st

At the same enterprises where tiles are made, rubber paving stones are produced. She goes to pave the paths. The paving stones are given not only a rectangular, but also a shaped shape, which allows adjacent elements to hold each other.

The method of laying tiles is “butt joint”. There are blind holes in each side of the rubber square. The tiles come with sleeves that are inserted into the holes. The resulting joints are of the tongue-and-groove type. These simple but reliable locks keep the tiles from moving.

Soft coverings for children's playgrounds on the street or in the yard are exposed to active exposure to the external environment. Children playing cause injuries to the coating. As a result, the site has to be repaired from time to time. From this point of view, rubber tiles are the most convenient covering option.

Necessary equipment

To lay the tiles you will need:

- Plates made of polymer chips, the thickness of which will be 20 mm;

- Rubber curb;

- Furniture knife;

- Adhesive solution specifically for rubber with polyurethane;

- Container for adhesive;

- Vacuum cleaner or broom;

- Chalk;

- Construction level or ruler;

- Notched spatula;

- Foam sponge;

- Rubber mallet.

Rolled rubber coatings

Rolls are laid faster than other types of crumb rubber coatings. Their use is justified when paving large areas. In terms of composition and manufacturing method, rolls differ little from tiles.

Rolls of crumb rubber Source www.intereco.ru

The rolls are laid end to end. They are connected to each other by tongue-and-groove locks. Parts extending beyond the boundaries of the site are cut off with a carpenter's knife or an electric jigsaw.

The monolithic crumb rubber coating has no cracks, so moisture remains on its surface and, if there is a slight slope, flows off the site. Paving with tiles or rolls does not have this advantage. Water penetrates under the tiles through the joints. To prevent the coating from “floating”, additional measures must be taken.

Caring for rubber tiles

Catalog of rubber tiles

The tiles are resistant to adverse weather conditions and temperature fluctuations, so there are no special tips for using and caring for the rubber coating. Thanks to its properties, the tiles are insured against the formation of mold, fungi and damage to the coating by rodents.

If the surface becomes dirty, just rinse it under medium pressure with water from a hose. Stubborn stains and stubborn dirt can be scrubbed with a brush dipped in soapy water.

Ice on the surface must be carefully chipped with an ice ax and removed with a stiff brush or shovel. Remove snow from the rubber surface with a broom or plastic flat shovel. If the area is very large, you can use a snowblower.

Preparation of bases for laying rubber coverings

The thoroughness of preparing the base on which crumbs, tiles or rolled material will be laid determines the durability of the coating. The simplest option is a leveled dirt area. Such preparation is often limited to when applying rubber coating for children's playgrounds in the country, where it is planned to install children's houses, ladders, and swings. But even in this case, it is important that the base is hygroscopic and has a slight slope for water drainage.

Rubber coating on a country playground Source www.sport-masterfibre.ru

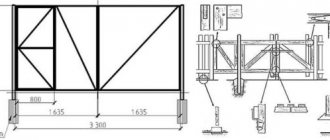

- More thorough work is being carried out to prepare the site on which a children's sports and play complex for numerous visitors will be built. Preparatory stages of work when creating a sand base:

- site marking;

- removal of vegetation, soil sampling while maintaining the slope (for water drainage);

- backfilling of the drainage layer, its thickness is usually 10 cm, the material is crushed stone;

- backfilling a 10-centimeter layer of sand onto a crushed stone bed;

- tamper with a high degree of compaction;

- laying geotextile fabric on which a rubber coating will be applied.

Sometimes the preparation of the base is completed by laying a layer of concrete or asphalt. When organizing places for street sports, the concrete or asphalt base is often “inherited”. Whatever base is used, it is necessary that water does not stagnate on it. That is, you need a slope of 2.5 mm for every 3 m of length.

Laying crumb rubber on an asphalt base Source https://blagsar.ru

What to consider during installation

When planning the installation of a polymer coating, it is necessary to take into account the following features of the material:

- Installation of tiles on a hard surface is carried out using an adhesive composition specially designed for this purpose.

- Laying the product on a ground or sandy surface will require removing the top layer of soil, and the products are connected end-to-end.

- The water outflow necessary for this coating can be created by installing the tiles with a slight slope of 1-2°.

- The coating will become more durable if you install a rubber curb.

- Installation must be carried out in dry weather and a temperature of 5°C, and it is preferable that there is no precipitation for another 2-3 days. This will allow the coating to be installed securely.

- The rubber sheet can be cut with a jigsaw, furniture knife or hacksaw.

When creating an original design from tiles of different colors, you need to make a sketch in advance, on which all the elements are then laid out in the right order.

Equipment and tools for applying crumb rubber coatings

Outdoor children's playgrounds and sports grounds can be of very different sizes. From a few square meters to the size of a stadium with athletics tracks. In the first case, you can use simple hand tools to lay the coating; in the second, you need serious equipment.

- Mixers . Used to obtain a working mixture of crumb rubber and binder. It is possible to use construction and more productive, specialized mixers.

- Trolleys for delivering the finished mixture to the installation site.

- Manual rolling rollers are the simplest tool for leveling the working mixture.

- Heated rollers . When using this tool, a better leveled surface is obtained.

Roller for laying crumb rubber with heating Source i.ytimg.com

- Machine for laying rubber crumbs . A simple mechanical device that evenly distributes the working mixture over the surface.

- Automatic coating layer. A complex device for installing coatings over large areas.

Seamless rubber coating paver Source www.smg-gmbh.de

Spray machine (spray) for applying a mixture of crumbs and a binder.

When laying rubber tiles and rolls, the set of tools is reduced to a regular mallet, with the help of which the covering elements are knocked together.

Laying methods

Rubber flooring sheets can be laid both from the edge of the room (platform) and from the middle. Polyurethane adhesive is applied to the base using a notched trowel, after which installation is immediately carried out. The sheets are laid end-to-end, without the slightest gap. Immediately after installation, the coating is rolled with a special roller to achieve a tight fit to the base and remove excess glue (they must be removed immediately with a clean rag). Average drying time is 24 hours. After this time, you can begin using the rubber coating.

It is important to ensure that no air remains under the canvas during installation. Particular attention should be paid to the joints of the canvases. If the edges of the coating are deformed and do not fit tightly to the base, you should press the problem area with a flat weight for several hours.

Briefly about the main thing

In the recent past, the most common type of surface for outdoor playgrounds was natural soil. It was replaced by artificial grass and rubber covering. They make children's games and sports safer. Most rubber flooring is a recycled product. They are made from old, worn-out tires. In terms of production method, appearance and performance characteristics, these coatings meet the requirements of the 21st century.

Ratings 0