The use of wood materials for the manufacture of various floorings and coverings installed on a summer cottage is justified from any point of view. Firstly, wood is a cheap building material that can be purchased at any construction organization. Secondly, the technology itself for assembling flooring from boards is so simple that any home craftsman who knows how to use a hacksaw and hammer can master it.

Wooden flooring at the dacha is one of the best options for arranging a children's playground or an impromptu stage used for amateur performances and performances. There are many known designs of such structures, intended for various purposes and differing in their configuration and size. Let's look at the most common of them in more detail.

Types of decking (sizes and shapes)

Floorings, or wooden platforms, from a construction point of view, are ordinary sheathing of pre-prepared sheathing, which in turn is laid directly on the ground or on logs. More reliable options can be considered structures whose foundation is made in the form of a foundation made of brick or concrete blocks. Sometimes such floorings are mounted on low supports made from pieces of logs or in the form of brick columns.

Before arranging a wooden platform in front of the house, you should think in advance about its shape and dimensions, which are usually determined by the intended purpose of the structure, namely:

- if you plan to stage home scenes and performances on the flooring, it is better to make it in the form of a rounded structure, convenient for spectators to view from one side;

- when making a children's playground for ball games, a standard rectangular platform will be more convenient, allowing you to select separate zones on the playing field;

- a corner platform can be used to enclose a garden pool, for example, or any other open body of water;

- If desired, outdoor garden furniture can be placed on diagonal decking as a convenient and level platform.

Functionally, the “flooring” category (without reference to a specific form) includes open verandas with and without fences, used for relaxation in a summer cottage. The simplest example of such a design is several boards laid close to one another and secured to joists.

Lags

The logs provide support for laying floor boards.

Wooden floors mounted on logs meet these requirements. They provide support for laying floor boards (they can be laid directly on wooden beams).

Logs are usually made of timber. They are fixed with a certain step, which depends on the thickness of the boards being laid. The logs can be laid on wooden beams, a concrete base or be recessed into the ground. This design allows for quick replacement of boards that have rotted. This is especially important in shower construction.

Materials used

In terms of durability and reliability, wood flooring is, of course, inferior to more durable structures made of concrete and metal. Their use is justified only in cases where the load on the surface is minimal. And by the nature of their use, they are more likely to be temporary (seasonal) objects that are dismantled with the onset of winter.

If these objects are intended for long-term use, the competent choice of the type of lumber in the form of boards becomes of paramount importance.

In this case, do-it-yourself wooden decks at the dacha, made in the yard or near the house, are usually made from wood material, which is distinguished by its density and durability.

Important! An ordinary board for arranging “long-term use” flooring is not entirely suitable.

To do this, you will need specially processed building material made of valuable and durable wood, designed in the form of blanks with locking joints (terrace or laminated board). It is clear that the costs of constructing such a flooring will increase noticeably, but over time they will pay off due to the operational longevity of the structure assembled on their basis.

How to decorate a podium

When the main work on arranging the flooring is completed, you can begin decorating. Initially, the podium is given the desired color using tinted oils, paints, impregnations or varnishes. It is advisable to use paints and varnishes that do not create a slippery glossy film on the surface of the wood.

If you want to bleach wood, there are suitable ready-made products already created in production.

They can easily be replaced with a solution of slaked lime (only a weak concentration), which will additionally protect the wood from mold.

Did the flat flooring not seem very impressive to you? Then cut round holes between the joists and place flowerpots in them or plant decorative low-growing shrubs.

But you just need to think about such decor in advance, at the stage of creating a drawing of the podium.

Wooden podiums look very impressive, into which shrubs and trees growing on the site are inscribed. When laying the supporting structure, logs are installed around the plants. They just leave free space for their growth and development, and when covering with boards, they make a “window” in the podium.

Under no circumstances should the frame be mounted to the trunk. A tree swaying in the wind can easily damage the decking.

If there are large stones and other natural objects on the site, then you can arrange a flooring, repeating their shape around the perimeter.

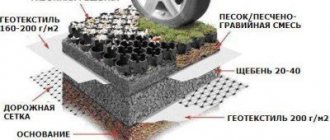

Geotextiles that protrude beyond the perimeter of the podium are cut and sprinkled with pebbles. Ornamental plants are planted along the edge, boxes or flowerpots with annual flowers are installed. The high podium is sewn up along the bottom with a board, which is nailed to the ends of the joists.

Wood is not the most durable material for constructing a playground or garden paths on a site. But proper processing of the material will allow the tree to be used for a very long time. And delight with its natural aesthetic appearance and warm, comfortable surface.

Ready-made modular flooring

To ensure that the flooring used at the dacha can be moved from place to place, building materials manufacturers have mastered the production of collapsible models. To implement this idea, the modular principle of assembling a structure consisting of a large number of standard cells was used.

For their manufacture, wood that is particularly weather-resistant or the same deck board (deck) is used.

Note! The cost of structures made from this material is noticeably higher than the same figure for simple solid flooring, which significantly reduces the demand for them.

If a cheaper regular board is used to make a modular platform, it is pre-treated with special impregnations and varnishes. In addition, a special waterproofing layer is provided on its reverse side during manufacturing. This modification of the system of wooden modules can significantly extend the service life of a homemade platform without excessively increasing its cost.

This coating is usually called garden parquet, which further emphasizes its similarity to its panel counterpart. It goes on sale in the form of square blanks with locks that allow you to quickly fasten them together. The result of assembly is a solid and fairly even canvas, resembling parquet flooring in appearance.

Pallet floor

One of the most inexpensive options for flooring a small summer house or shower room

One of the most inexpensive options for flooring a small summer house or shower room is the use of wooden pallet boards. Pallet boards are carefully separated from the pallets without damaging the wood, impregnated with an antiseptic and laid on the logs. Then they can be cleaned and used to refine the varnish, or they can be leveled with plywood and covered with linoleum.

Advice: you can make flooring only from boards of only those pallets. The origin and conditions of use of which are known to you.

The flooring on the second floor does not require insulation. This overlap is performed single. The floor boards are attached to the floor beams, and from below (like the ceiling of the first floor) they are covered with plywood, fiberboard sheets or panels.

Pole flooring

If there are so-called floating soils at the dacha site, it is recommended to install the flooring on support pillars that are not completely buried in the ground. To obtain a floating effect, the supports rest their base on concrete shoes with rectangular landing sockets. Each such shoe is made in the form of a square with a side of 400 and a thickness of 15 mm.

Installation of supports

Typical support posts are made from solid timber or glued together from thick boards and are equipped with a fastening spike used to secure them in the foundation soles.

Installation of support pillars is carried out in the following sequence:

- first, the platform for the flooring is marked for the installation of soles or shoes, taking into account that the supports should be approximately 1.4 meters apart from each other (these distances are measured from the center of the flooring area);

- after marking the points for installing supports in the designated areas, the top layer of soil is removed, and then crushed stone is poured there and compacted well;

- finished shoes with anchor eyes in the upper part are placed on compacted crushed stone and filled with concrete mortar;

- after this, the supports are installed in the shoes and fixed in the anchors with bolts.

Important! When securing the supports in the shoes, their upper cut should be leveled in order to bring them to the same height.

It is also important to ensure that their tops are located exactly in a line parallel to the wall of the nearest building. To extend the service life of the wooden platform, the surface of the pillars is treated with antiseptic compounds.

Preparation and installation of logs (straps)

After strengthening the supports, you can begin to arrange the sheathing, consisting of wooden beams or joists. First of all, the external strapping elements are laid out, which are fixed at the corners of the structure with their ends end-to-end. Small staples can be used to secure them.

Intermediate beams are placed parallel to the outer ones, and their height position is constantly controlled by means of a level. To fix them on the heads of the supports, it is recommended to use large nails or special galvanized screws. In a situation where the platform has several levels, the lower logs are nailed first and only then the installation of the upper beams begins.

When laying at one level, it is important to ensure that the upper planes of the intermediate beams are located at the same level as the trim beams.

Double plank floor with subfloor

It differs from single ones in that the bottom, rough layer is attached to the bottom of the laid joists or beams, using slats.

It differs from single ones in that the bottom, rough layer is attached to the bottom of the laid joists or beams, using slats. Insulation boards and vapor barrier material are laid on the rough boards. Boards with wane, unhewn boards, parts of wooden pallets, etc. can be used as rough materials.

To prevent the floor boards from rotting, you need to create an air gap between the finishing layer of boards and the insulation for ventilation. Sometimes a simplified, budget version of such a double floor is made - without laying insulation boards.

Safety comes first!

Regardless of who will be the main “inhabitant” of the house: a five-year-old fidget or a ten-year-old pioneer, parents should first of all think about safety precautions and only then about the appearance of the structure.

Observe the permitted height level. The younger the children, the closer to the ground the platform should be located. But even if your child has long outgrown the senior group of kindergarten, it is better to limit the height to 2-2.5 m. And of course, do not forget to install a safe ladder!

Don't skimp on materials and fasteners . This is especially true for the arrangement of load-bearing structures. If you are not sure about the quality of the wood of the board or pile, set the material aside.

Try to drill fewer holes . In countries where both amateurs and full-fledged construction companies are engaged in the construction of tree houses, special fastening systems can be purchased in hardware stores. This is still a novelty for us, but still remember: 2 large fasteners are better than 20 small ones. Because the fewer holes, the less likely it is that the tree will suffer from diseases and pests.

Maximum work “on the ground” . Do not expose yourself and your loved ones to danger - do all the work that is possible below. Fitting boards, drilling holes for bolts, assembling a ladder - you don't need to climb a tree to do all this. The better the preparation, the faster the assembly process will go.

Install safety railings . A blank wall, turned balusters, rope or wire mesh - the main thing is that the handrails are reliable enough.

Coordinate the work with your neighbors . Before setting up a treehouse on your property, discuss it with your neighbors. Will the walls of the building obscure their favorite hydrangea? Will the neighbor's Rex's booth be within the range of the cubes flying out of the windows of the house? Discuss all possible options.

Device technology

Before carrying out the main work, it is necessary to prepare tools and materials:

- edged boards of the required length;

- saw cuts;

- garden parquet;

- material for making borders made of metal, wood or concrete;

- waste machine oil or drying oil for wood processing;

- materials for sealing gaps (pebbles, sand, gravel), alternative: sand with cement.

Construction tools used include a hacksaw, tape measure, plane, mallet, shovel, electric planer, and chainsaw.

The process of installing wooden paths is performed in the following sequence:

- We mark the area where the future path will be laid using wooden pegs and a cord (we set the width of the path within 0.5–1 meter).

- We remove the layer of turf from the soil; its thickness depends on the type of material used. The coating should be a couple of centimeters higher than the rest of the surface, taking into account the backfill. The depth of the trench is between 20–40 centimeters.

- We cover the bottom of the ditch with plastic film, which will protect the wood from moisture penetration and prevent the growth of weeds. We make a cushion of gravel and sand and compact the mixture with a tamper.

- We install a concrete or metal border at the edges of the trench.

- We lay the covering for the sections of logs, garden parquet, timber or boards. Before carrying out installation work, we cut the lumber into pieces of the required length, treat the surfaces with an electric planer, and cover them with an antiseptic and impregnation.

- We lay out the lumber according to a pre-developed pattern (in a continuous layer or with gaps). The recommended distance between beams, boards or stumps is within 5–8 centimeters.

- We level the laid materials using a mallet. We constantly check the horizontality of the coating using a building level.

At the final stage of work, we fill the gaps with bulk materials, gravel or pebbles. You can use a mixture of cement and sand in a ratio of 1:6.

Finishing

Wooden floors in a room should not only be durable, but also beautiful.

Wooden flooring in a room should not only be durable and rigid. Beautiful flooring: linoleum, carpet or varnish, enamels of various shades can make the floor attractive and comfortable for walking. For example, varnishes will not only highlight the structure of the wood, but also create a protective surface layer. If necessary, the easiest way to level a plank floor is with sheets of plywood.

The choice of flooring design in a wooden house and outbuildings (sheds, showers, etc.) depends on: the purpose of the room, seasonality of use, and the presence of heating. The costs of its arrangement can be reduced if improvised materials are used during construction, for example, wood from used wooden pallets.

Preparing for construction

If the house is still intended for children, then the task is greatly simplified. You can make it very small. But of course, in any case, it should also be beautiful - and extremely safe in every sense, from height to strength and ease of design.

Before you start building a house, you need to be aware of its future tasks and initial characteristics.

Objectives and qualities of the future house for a child

Let's remember our childhood. What would we want if our parents promised us such a house? Let's sum it up:

- so that it looks somewhat similar to the real one;

- so that it has a floor for a cozy arrangement inside;

- so that there is a waterproof roof for sitting there in the rain;

- the house itself should not be fortified too low.

Now let's look at the problem from an adult's point of view:

- the house must be firmly made so that rowdy children cannot destroy it under any circumstances;

- it should not be fortified too high - also for safety reasons;

- he must have a strong ladder, and preferably not a rope one.

Selecting Support Trees

Much of the design, its strength and reliability, depends on the trees available. The best option is if we have a strong tree on our site with a powerful trunk and thick branches, around which we can build a deck. But there are some limitations here. Old hollow trees with cavities and dry branches are not suitable.

Scheme of building a house on a large tree: the height of the lower branches and the building platform are shown

Ideally, when a thick trunk is bifurcated or "untuned", then there is almost no need to make additional supports for safety and strength.

The house is securely fastened on three thick branches and does not require additional supports

More often than not, there is no such large tree on the site, and it is necessary to design a house on two or more thinner trees.

House on two trees without additional supports

Often in these cases additional supports are needed.

A house on two trees needs two additional supports

If the trees are completely unreliable, then the house is built entirely on supports, and the tree acts more like a decorative addition.

Recent Posts Chainsaw or electric saw - what to choose for the garden? 4 mistakes when growing tomatoes in pots that almost all housewives make Secrets of growing seedlings from the Japanese, who are very sensitive to the soil

The type of wood also matters. Good - in descending order - oak, maple, ash. But they also need to remove thin or dry branches. Species with fragile roots - birch, chestnut and especially poplar - can collapse entirely. Linden wood is viscous and soft, making it difficult to attach a house structure to it. Pine is thorny and is considered a haven for ants. It is not recommended to build it on fruit trees for other reasons - there is no need to disrupt normal fruiting.

Although in my childhood I had a house high on a huge old apricot tree (this is the Central Asian name for an apricot tree). I came up with such a shelter myself, and my dad helped lay the floor between four thick trunks, build shelves and seats, and stretch a tarpaulin on top instead of a roof. In the evenings, my house was illuminated by three battery-powered flashlights. Of course, it was possible to “live” there only during the warm season, but in the south this time is very long.

Preliminary estimates

- Select a tree or trees. It is advisable to photograph them from different angles - this will help when creating a sketch and choosing the design of the future house.

- We are figuring out how many children we need to build a shelter for so that it can withstand all the loads. We feel free to add all our neighbors to our children; they will not miss such an adventure. This affects the size and capital of the building. But the size and weight must match the chosen tree.

- Let the children decide for themselves what they need: a headquarters, a house itself, or just an observation deck with a roof. The design of the house depends on this: whether windows, doors, furniture are needed inside. We immediately estimate the type of windows, doors, furniture.

- Based on all this data, we decide how the structure will be strengthened - around the trunk, on branches or on autonomous supports.

- Now you can make a drawing, and behind it - drawings.

Drawing of a two-level house on a large tree with a sturdy staircase and a veranda

An example of the implementation of one of the drawing projects.

This cozy house is built according to the drawing

Limits of Possibilities

When we have decided on the type of house and its location, it is necessary to outline the boundaries of our capabilities:

- do we have carpentry and plumbing skills;

- Do you already have building materials? Often boards and hardware remain at the dacha from construction and repairs;

- If you need to buy something additional or buy building materials entirely, how much do we expect to spend?

When this task is solved, we proceed to the next stage.

Drawing or drawing

To begin with, in search of ideas, we look on the Internet and select, in our opinion, examples of houses and their drawings that are suitable for our conditions.

Photo gallery: examples of house drawings

The drawing of a low-lying house with a minimum of complex details is also very simple. Drawings for attaching the platform to a tree for the case of diverging branches - and piles for other cases. This tree house is more like a platform on stilts. The drawing of the frame is made quite skillfully. There are also such drawings - completely by hand. Sketch in 3DMax, if you own it, is the best solution

But, having decided on the height of the platform from the ground, the area and height of the house itself, and the method of attaching it to the tree, we will draw the invented structure by hand. We will attach it directly to two rather thick maples. Their damage will not be so great as to seriously damage the trees. The ladder is usually attached not to the tree due to its growth, but to the house itself. We abandoned the idea of using a rope ladder: although it is an additional romance for children, such a ladder is much less safe than a wooden one with steps.

The diagram of the house as a whole, side view, gives an idea of the height and overall dimensions

The next scheme will be the platform of the house. The floor inside will be plywood, the veranda will be made of boards.

The platform of the house is also drawn by hand, the dimensions are indicated

Now you need to roughly estimate how much material will be used. We do this right in the picture.

The layout of the boards does not pretend to be accurate and gives the most general idea

Material selection

I am sure that there is always a great temptation to use cheap chipboard for the floor, channels for the beams and polycarbonate for the roof. But I am a staunch supporter of environmentally friendly buildings, and on my site I have always built from natural materials. Therefore, I do not insist at all, but I advise you to do the same. It will be much more useful for children. So, we choose a tree: timber and boards of different sections. The most unsustainable parts of the house will be unbreakable plexiglass for the dormer windows, plywood and thin panels of pressed wood; we are forced to prefer them to boards because of their greater lightness. The windows will look more like shutters - this will eliminate the danger of glass breaking. The roof will be covered with strips of thin galvanized steel - standing seam metal roofing. Since, as planned, we do not have supports dug into the ground, we do not need resin or grease for impregnation.

Let's estimate how much we need.

Attention: the calculation of materials is very approximate, and the price is not indicated due to seasonal and geographical fluctuations.

Table: approximate calculation of materials

| Position | Name | Definitions | Required quantity |

| 1 | Edged board | 50x250x6000 mm | about 1 m3 |

| 2 | Edged board | 25x150x6000 mm | about 0.5 m3 |

| 3 | timber | 150x150x6000 mm | about 1 m3 |

| 4 | Support beams | 200x200x3000 mm | 8 pieces |

| 5 | Plywood | 10x1200x2400 | 4 sheets |

| 6 | Isotex Luxor wall panels with vinyl coating or any similar | 580×2700 mm | 4 packs of 4 panels (package area - 6.26 m2) |

| 7 | Plexiglas (plexiglass) | 600x600 mm | 4 sheets |

| 8 | Metal seam roofing (panels) | 0.4x1420x710 mm | about 10 m2 |

| 9 | Galvanized self-tapping screws | Different sizes | 4 kg |

| 10 | Metal mounting plates and angles | Different sizes | As needed, but not less than 50 pcs. |

| 11 | Window and door hinges, left and right | – | 4 small (2 different), 3 large (identical) |

| 12 | Antiseptic impregnation for wood | – | As needed |

| 13 | Varnish, paint | – | As needed |

Required Tools

- hammer;

- planer and jointer;

- electric or hand drill with a set of drills and grinding wheels;

- screwdriver;

- building level or level;

- hacksaw saw (or circular saw);

- brushes for applying antiseptic impregnation, grease and varnish (if desired).

Caring for wooden paths

During use, garden sidewalks crack, rot and lose their attractiveness over time. In order to bring the appearance of the path back to normal in a timely manner, it is necessary to carefully inspect it annually. When creating paths, it is recommended to save the main and decorative materials that will be needed for future repairs.

Mandatory procedures include:

- Cleaning paths from debris and dirt.

- Treating stumps with antiseptic agents.

- Replacement of damaged elements with new ones.

Thus, wooden paths are aimed at creating ease of movement around the garden plot, as well as maintaining a neat appearance of the area. Creating such an element of landscape design is not difficult and it does not require large financial costs. If you make a garden sidewalk from saw cuts, following step-by-step instructions, and also carry out all the necessary maintenance steps, then such a functional part of the exterior will delight the owner for many years.

Requirements for wood materials

A prerequisite is that initially there should be no traces of rotting on the surface, since already infected wood cannot be cured with any impregnation. The exception is blue - a fungal infection of a bluish color. It does not destroy the structure of the wood, and you can get rid of it with special bleaches. The product is applied to the stain for 25-55 minutes in several layers. After treatment, the blue discolors and disappears.

Much more dangerous are spots of black, green or red color. They need to be removed as deeply as possible, and then bleaches and impregnations must be used.

Photoaging is another dangerous factor for wood. The sun's rays destroy the lignin that glues the fibers together, cracks appear, and the wood itself turns gray. To avoid this, it is recommended to use impregnations for outdoor use with a UV filter. They protect wood from harmful radiation, preserve its color and structure.